Abstract

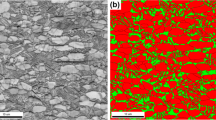

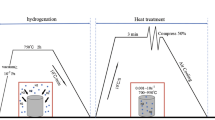

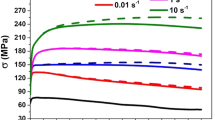

Based on the flow stress data obtained from the isothermal hot compression tests, the processing maps of Ti-6Al-4V alloy were developed based on the instability criteria of Prasad, Malas, and Murty. The validation of the processing maps was achieved by investigating the microstructures of compressed Ti-6Al-4V alloy specimens. The results showed that the power dissipation maps obtained using the criteria of Prasad and Murty exhibited similar distribution, whereas the instability domains obtained by various instability criteria had great differences. Microstructure analysis showed that the instability domains determined by Murty’s criterion were more accurate than those determined using other criteria.

Similar content being viewed by others

References

G. Chen, C.Z. Ren, X.D. Qin, and J. Li, Temperature Dependent Work Hardening in Ti-6Al-4V Alloy Over Large Temperature and Strain Rate Ranges: Experiments and Constitutive Modeling, Mater. Des., 2015, 83, p 598–610

R. Sahoo, B.B. Jha, and T.K. Sahoo, Effect of Primary Alpha Phase Variation on Mechanical Behaviour of Ti-6Al-4V Alloy, Mater. Sci. Technol., 2015, 31, p 1486–1494

F.Z. Wang, J. Zhao, N.B. Zhu, and Z.L. Li, A Comparative Study on Johnson–Cook Constitutive Modeling for Ti-6Al-4V Alloy Using Automated Ball Indentation (ABI) Technique, J. Alloys Compd., 2015, 633, p 220–228

S. Bruschia, S. Poggiob, F. Quadrinib et al., Workability of Ti-6Al-4V Alloy at High Temperatures and Strain Rates, Mater. Lett., 2004, 58, p 27–28

B.P. Severino, A.A. Couto, D.A.P. Reis, C.L. Aguiar, M. Castagnet, and C. Moura Neto, Study of High Temperature Mechanical Behavior of the Thermally Oxidized Ti-6Al-4V Alloy, Mater. wis. Werkstofftech., 2014, 45, p 269–280

L. Filice, F. Gagliardi, S. Lazzaro et al., FE Simulation and Experimental Considerations on TI Alloy Superplastic Forming for Aerospace Applications, Int. J. Mater. Form., 2010, 3, p 41–46

Y.V.R.K. Prasad, T. Seshacharyulu, S.C. Medeiros et al., Influence of Oxygen Content on the Forging Response of Equiaxed (α + β) Preform of Ti-6Al-4V: Commercial vs. ELI Grade, J. Mater. Process. Technol., 2001, 108, p 320–327

M.J. Zhang, F.G. Li, S.Y. Wang et al., Characterization of Hot Deformation Behavior of a P/M Nickel-Base Superalloy Using Processing Map and Activation Energy, Mater. Sci. Eng. A, 2010, 527, p 6771–6779

G.L. Ji, F.G. Li, Q.H. Li et al., Development and Validation of a Processing Map for Aermet100 Steel, Mater. Sci. Eng. A, 2010, 527, p 1165–1171

R. Raj, Development of a Processing Map for Use in Warm-Forming and Hot-Forming Process, Metall. Trans. A, 1981, 12A, p 1089–1097

Y.V.R.K. Prasad and T. Seshacharyulu, Modelling of Hot Deformation for Microstructural Control, Int. Mater. Rev., 1998, 43, p 243–258

J.C. Malas and V. Seetharaman, Using Material Behavior Models to Develop Process Control Strategies, JOM, 1992, 44, p 8–13

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu et al., Modeling of Dynamic Material Behavior in Hot Deformation: Forging of Ti-6424, Metall. Trans. A, 1984, 15, p 1883–1892

S.V.S.N. Murty and B.N. Rao, On the Development of Instability Criteria During Hot Working with Reference to IN718, Mater. Sci. Eng. A, 1998, 254, p 76–82

N.K. Park, J.T. Yeom, and Y.S. Na, Characterization of Deformation Stability in Hot Forging of Conventional Ti-6Al-4V Using Processing Maps, Mater. Sci. Eng. A, 2002, 130–131, p 540–545

J. Luo, M.Q. Li, H. Li et al., Effect of the Strain on the Deformation Behavior of Isothermally Compressed Ti-6Al-4V Alloy, Mater. Sci. Eng. A, 2009, 88–89, p 88–95

Y. Wang, W.Z. Shao, L. Zhen et al., Flow Behavior and Microstructures of Superalloy 718 During High Temperature Deformation, Mater. Sci. Eng. A, 2008, 497, p 479–486

J. Lin and F.P.E. Dunne, Modelling Grain Growth Evolution and Necking in Superplastic Blow-Forming, Int. J. Mech. Sci., 2001, 43, p 595–609

J. Luo, M.Q. Li, W.X. Yu, and H. Li, The Variation of Strain Rate Sensitivity Exponent and Strain Hardening Exponent in Isothermal Compression of Ti-6Al-4V Alloy, Mater. Des., 2010, 31, p 741–748

Y.Q. Ning, B.C. Xie, H.Q. Liang et al., Dynamic Softening Behavior of TC18 Titanium Alloy During Hot Deformation, Mater. Des., 2015, 71, p 68–77

S.V.S.N. Murty, B.N. Rao, and B.P. Kashyap, Development and Validation of a Processing Map for Zirconium Alloys, Model. Simul. Mater. Sci. Eng., 2002, 10, p 503–520

S.V.S.N. Murty, B.N. Rao, and B.P. Kashyap, Processing Maps for Hot Deformation of α2 Aluminide Alloy Ti-24Al-11Nb, J. Mater. Sci., 2002, 37, p 1197–1201

R. Ding and Z.X. Guo, Microstructural Evolution of a Ti-6Al-4V Alloy During β-Phase Processing: Experimental and Simulative Investigations, Mater. Sci. Eng. A, 2004, 365, p 172–179

S.M. Abbasi and A. Momeni, Effect of Hot Working and Post-deformation Heat Treatment on Microstructure and Tensile Properties of Ti-6Al-4V Alloy, Trans. Nonferrous Met. Soc. China, 2011, 21, p 1728–1734

T. Seshacharyul, S.C. Medeiros, W.G. Frazier et al., Hot Working of Commercial Ti-6Al-4V with an Equiaxed α − β Microstructure: Materials Modeling Considerations, Mater. Sci. Eng. A, 2000, 284, p 184–194

Acknowledgments

The authors gratefully acknowledge the financial support received from Innovation Foundation of Western Materials (XBCL-3-19), Planned Scientific Research Project of Education Department of Shaanxi Provincial Government (15JS056), Industrial Science and Technique Key Project of Shaanxi Province (2016GY-207), Province Natural Science Foundation of Shaanxi (2014JM6230), and Service Place Special Plan Project Funded by the Shaanxi Province Education Department (14JF013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cai, J., Zhang, X., Wang, K. et al. Development and Validation of Processing Maps for Ti-6Al-4V Alloy Using Various Flow Instability Criteria. J. of Materi Eng and Perform 25, 4750–4756 (2016). https://doi.org/10.1007/s11665-016-2296-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2296-9