Abstract

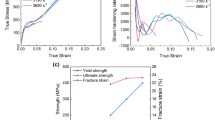

The effect of grain size and current density on deformation behavior during electrically assisted tension of Ti-6Al-4V alloy was investigated. The microstructural variations under different conditions were observed by optical microscope, SEM and TEM. The dislocation density was quantified by x-ray diffraction technique. The decrease in grain size could increase the elongation growth and stress reduction during electrically assisted tension. Fine grain size specimens can reach higher temperature than coarse grain specimens. With increasing current density, wider and deeper dimples on the fracture surfaces were observed, and less dislocation density and pileups were found in comparison with room-temperature tension without current. The dislocation density has a 62.1% reduction at 10.48 A/mm2 compared with room-temperature tension for 9.2 μm grain size specimens.

Similar content being viewed by others

References

H. Karbasian and A.E. Tekkaya, A Review on Hot Stamping, J. Mater. Process. Technol., 2010, 210, p 2103–2118

C.D. Ross, D.B. Irvin, and J.T. Roth, Manufacturing Aspects Relating to the Effects of Direct Current on the Tensile Properties of Metals, ASME J. Eng. Mater. Technol., 2007, 129, p 342–347

T.A. Perkins, T.J. Kronenberger, and J.T. Roth, Metallic Forging Using Electrical Flow as an Alternative to Warm/Hot Working, ASME J. Manuf. Sci. Eng., 2007, 129, p 84–94

J. Magargee, F. Morestin, and J. Cao, Characterization of Flow Stress for Commercially Pure Titanium Subjected to Electrically-Assisted Deformation, ASME J. Eng. Mater. Technol., 2013, 135, p 041003

B. Kinsey, G. Cullen, A. Jordan, and S. Mates, Investigation of Electroplastic Effect at High Deformation Rates for 304SS and Ti-6Al-4V, CIRP Ann. Manuf. Technol., 2013, 62, p 279–282

J.T. Roth, I. Loker, D. Mauck, M. Warner, S.F. Golovashchenko, and A. Krause, Enhanced Formability of 5754 Aluminum Sheet Metal Using Electric Pulsing, Trans. N Am. Manuf. Res. Inst. SME, 2008, 36, p 405–412

P.C. Song, X.F. Li, W. Ding, and J. Chen, Electroplastic Tensile Behavior of 5A90 Al–Li Alloys, Acta Metall. Sin. (Engl. Lett.), 2014, 27, p 642–648

X.F. Li, Q. Zhou, S.J. Zhao, and J. Chen, Effect of Pulse Current on Bending Behavior of Ti6Al4V Alloy, Procedia Eng., 2014, 81, p 1799–1804

T.J. Kronenberger, D.H. Johnson, and J.T. Roth, Coupled Multifield Finite Element Analysis Model of Upsetting Under an Applied Direct Current, ASME J. Manuf. Sci. Eng., 2009, 131, p 0310031–0310038

J.-H. Roh, J.-J. Seo, S.T. Hong, M.-J. Kim, H.N. Han, and J.T. Roth, The Mechanical Behavior of 5052-H32 Aluminum Alloys Under a Pulsed Electric Current, Int. J. Plast., 2014, 58, p 84–99

C. Li, K.F. Zhang, S.S. Jiang, and Z.P. Zhao, Pulse Current Auxiliary Bulging and Deformation Mechanism of AZ31 Magnesium Alloy, Mater. Des., 2012, 34, p 170–178

A.A. Potapova and V.V. Stolyarov, Deformability and Structural Features of Shape Memory TiNi alloys Processed by Rolling with Current, Mater. Sci. Eng. A, 2013, 579, p 114–117

Z.S. Xu, Z.H. Lai, and Y.X. Chen, Effect of Electric Current on the Recrystallization Behavior of Cold Worked α-Ti, Scr. Metall., 1988, 22, p 187–190

H. Conrad, Effects of Electric Current on Solid State Phase Transformations in Metals, Mater. Sci. Eng. A, 2000, 287, p 227–237

X.X. Ye, Z.T.H. Tse, G.Y. Tang, and G.L. Song, Mechanical Properties and Phase Transition of Biomedical Titanium Alloy Strips with Initial Quasi-Single Phase State Under High-Energy Electropulses, J. Mech. Behav. Biomed. Mater., 2015, 42, p 100–115

M.S. Siopis and B.L. Kinsey, Experimental Investigation of Grain and Specimen Size Effects During Electrical-Assisted Forming, ASME J. Manuf. Sci. Eng., 2010, 132, p 0210041–0210047

R. Fan, J. Magargee, P. Hu, and J. Cao, Influence of Grain Size and Grain Boundaries on the Thermal and Mechanical Behavior of 70/30 Brass Under Electrically-Assisted Deformation, Mater. Sci. Eng. A, 2013, 574, p 218–225

L.F. Peng, J.M. Mai, T.H. Jiang, X.M. Lai, and Z.Q. Lin, Experimental Investigation of Tensile Properties of SS316L and Fabrication of Micro/Meso Channel Features by Electrical-Assisted Embossing Process, ASME J. Micro Nano-Manuf., 2014, 2, p 021002

ASTM E112-96 e2, Standard Test Methods for Determining Average Grain Size, ASTM International, West Conshohocken, 2004

H. Conrad, Electroplasticity in Metals and Ceramics, Mater. Sci. Eng. A, 2000, 287, p 276–287

P. Gay, P. Hirsch, and A. Kelly, The Estimation of Dislocation Densities in Metals from X-ray Data, Acta Metall., 1953, 1, p 315–319

N.E. Paton and W. Backofen, Plastic Deformation of Titanium at Elevated Temperatures, Metall. Trans., 1970, 1, p 2839–2847

Y. Liu, L. Wang, F. Feng, X.D. Lu, and B.J. Zhang, Effect of Pulse Current on Tensile Deformation Behavior of IN718 Alloy, Adv. Mater. Res., 2012, 509, p 56–63

X.F. Li, S. Wang, S.J. Zhao, W. Ding, J. Chen, and G.H. Wu, Effect of Pulse Current on the Tensile Deformation of SUS304 Stainless Steel, J. Mater. Eng. Perform., 2015, 24, p 5065–5070

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Nos. 51105248, 51475295). We expressed our sincere thanks for their financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, X., Ji, B., Zhou, Q. et al. Influence of Grain Size on Electrically Assisted Tensile Behavior of Ti-6Al-4V Alloy. J. of Materi Eng and Perform 25, 4514–4520 (2016). https://doi.org/10.1007/s11665-016-2268-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2268-0