Abstract

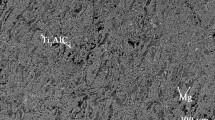

AZ31-Mg2Si in situ composites were prepared from AZ31 Mg alloy and Si particles by a gravity casting method. Several parameters, such as Si content, normal load, and environmental temperature, were varied in order to study their effects on the composite dry sliding wear properties. Tensile properties and hardness of the composites were also investigated. The obtained results showed that the wear resistance, yield strength, and hardness of the AZ31-Mg2Si composites increased with size and quantity of the Mg2Si phase. However, when the environmental temperature increased from 25 to 190 °C, the composite wear resistance and ultimate tensile strength gradually decreased due to softening of the AZ31 matrix.

Similar content being viewed by others

References

T. Tanski, K. Labisz, and J. Szewczenko, TEM Investigations of (Ti, Si)N Layer Coated on Magnesium Alloy Using PVD Technique, Solid State Phenom., 2013, 203–204, p 198–203

C. Taltavull, B. Torres, A.J. López, and J. Rams, Dry Sliding Wear Behavior of AM60B Magnesium Alloy, Wear, 2013, 301, p 615–625

P. Poddar, A. Das, and K.L. Sahoo, Dry Sliding Wear Characteristics of Rheocast Mg–Sn Based Alloys, Mater. Des., 2014, 54, p 820–830

M.E. Moussa, M.A. Waly, and A.M. El-Sheikh, Combined Effect of High-Intensity Ultrasonic Treatment and Ca Addition on Modification of Primary Mg2Si and Wear Resistance in Hypereutectic Mg–Si Alloys, J. Alloys Compd., 2014, 615, p 576–581

A. Srinivasan, J. Swaminathan, U.T.S. Pillai, K. Guguloth, and B.C. Pai, Effect of Combined Addition of Si and Sb on the Microstructure and Creep Properties of AZ91 Magnesium Alloy, Mater. Sci. Eng., A, 2008, 485, p 86–91

M.S. Dargusch, G.L. Dunlop, A.L. Bowles, K. Pettersen, and P. Bakke, The Effect of Silicon Content on the Microstructure and Creep Behavior in Die-Cast Magnesium AS Alloys, Metall. Trans. A, 2004, 35, p 1905–1909

L.H. Liao, X.Q. Zhang, H.W. Wang, X.F. Li, and N.H. Ma, Influence of Sb on Damping Capacity and Mechanical Properties of Mg2Si/Mg–9Al Composite Materials, J. Alloys Compd., 2007, 430, p 292–296

Y.Z. Lu, Q.D. Wang, X.Q. Zeng, Y.P. Zhu, and W.J. Ding, Effects of Rare Earths on the Microstructure, Properties and Fracture Behavior of Mg–Al Alloys, Mater. Sci. Eng., A, 2001, 301, p 255–258

W.M. Gan, K. Wu, M.Y. Zheng, X.J. Wang, H. Chang, and H.-G. Brokmeier, Microstructure and Mechanical Property of the ECAPed Mg2Si/Mg Composite, Mater. Sci. Eng., A, 2009, 516, p 283–289

W. Guo, Q.D. Wang, B. Ye, H. Zhou, and J.F. Liu, Microstructure and Mechanical Properties of AZ31-Mg2Si In Situ Composite Fabricated by Repetitive Upsetting, Trans. Nonferr. Met. Soc. China, 2014, 24, p 3755–3761

ASTM G133-02, Standard TST method for linearly reciprocating ball-on-flat sliding wear, West Conshohocken, PA: ASTM.

Q.C. Jiang, H.Y. Wang, Y. Wang, B.X. Ma, and J.G. Wang, Modification of Mg2Si in Mg–Si Alloys with Yttrium, Mater. Sci. Eng., A, 2005, 392, p p130–p135

Y. Carbonneau, A. Couture, A. Van Neste, and R. Tremblay, On the Observation of a New Ternary MgSiCa Phase in Mg–Si Alloys, Metall. Trans. A, 1998, 29, p 1759–1763

J.F. Archard, Contact and Rubbing of Flat Surfaces, J. Appl. Phys., 1953, 24, p 981–988

S.C. Sharma, B. Anand, and M. Krishna, Evaluation of Sliding Wear Behavior of Feldspar Particle-Reinforced Magnesium Alloy Composites, Wear, 2000, 241, p 33–40

L.H. Qi, J.T. Guan, J. Liu, J.M. Zhou, and X.L. Wei, Wear Behaviors of Cf/Mg Composites Fabricated by Extrusion Directly Following Vacuum Pressure Infiltration Technique, Wear, 2013, 307, p 127–133

B.V.M. Kumar and B. Basu, Evolution in Friction and Wear of Mg–SiCp Composites: Influence of Fretting Duration, J. Mater. Res., 2005, 20, p 801–812

P. Abachi, A. Masoudi, and K. Purazrang, Dry Sliding Wear Behavior of SiCp/QE22 Magnesium Alloy Matrix Composites, Mater. Sci. Eng., A, 2006, 435–436, p 653–657

M.A. Martinez, A. Martin, and J. Llorca, Wear of Al–Si Alloys and Al–Si/SiC Composites at Ambient and Elevated Temperatures, Scr. Metall. Mater., 1993, 28, p 207–212

Acknowledgments

The present research was sponsored by the National Natural Science Foundation of China (NSFC) under Grant Nos. 51404151 and 51374145, Scientific Research and Development Foundation from Jiangxi Academy of Sciences under Grant Nos. 2015-YYB-11 and 2015-XTPH1-11, China Postdoctoral Science Foundation (CPSF) under Grant No. 2014M561466, and Shanghai Postdoctoral Scientific Program under Grant No. 14R21411000.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, W., Wang, D., Fu, Y. et al. Dry Sliding Wear Properties of AZ31-Mg2Si Magnesium Matrix Composites. J. of Materi Eng and Perform 25, 4109–4114 (2016). https://doi.org/10.1007/s11665-016-2263-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2263-5