Abstract

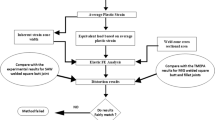

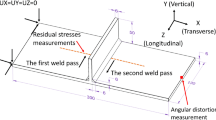

Inherent strain analysis has been successfully applied to predict welding deformations of large-scale structural components, while thermal-elastic-plastic finite element method is rarely used for its disadvantages of long calculation period and large storage space. In this paper, a hybrid model considering nonlinear yield stress curves and multi-constraint equations to thermal-elastic-plastic analysis is further proposed to predict welding distortions and residual stresses of large-scale structures. For welding T-joint structural steel S355JR by metal active gas welding, the published experiment results of temperature and displacement fields are applied to illustrate the credibility of the proposed integration model. By comparing numerical results of four different cases with the experiment results, it is verified that prediction precision of welding deformations and residual stresses is apparently improved considering the power-law hardening model, and computational time is also obviously shortened about 30.14% using multi-constraint equations. On the whole, the proposed hybrid method can be further used to precisely and efficiently predict welding deformations and residual stresses of large-scale structures.

Similar content being viewed by others

References

O.T. Ola and F.E. Doern, Fusion Weld Ability Studies in Aerospace AA7075-T651 Using High-Power Continuous Wave Laser Beam Techniques, Mater. Des., 2015, 77, p 50–58

J. Adamus and P. Lacki, Analysis of Forming Titanium Welded Blanks, Comput. Mater. Sci., 2014, 94, p 66–72

W. Liu, J.J. Ma, M.M. Atabaki, and R. Kovacevic, Joining of Advanced High-Strength Steel to AA 6061 Alloy by Using Fe/Al Structural Transition Joint, Mater. Des., 2015, 68, p 146–157

Y.M. Rong, Z. Zhang, G.J. Zhang, C. Yue, Y.F. Gu, Y. Huang, C.M. Wang, and X.Y. Shao, Parameters Optimization of Laser Brazing in Crimping Butt Using Taguchi and BPNN-GA, Opt. Laser. Eng., 2015, 67, p 94–104

W.J. He, B.F. Luan, R.L. Xin, J.B. Xu, and Q. Liu, A Multi-scale Model for Description of Strain Localization in Friction Stir Welded Magnesium Alloy, Comput. Mater. Sci., 2015, 104, p 162–171

D. Deng, H. Murakawa, and W. Liang, Prediction of Welding Distortion in a Curved Plate Structure by Means of Elastic Finite Element Method, J. Mater. Process. Technol., 2008, 203, p 252–266

Y. Ueda, Y.C. Kim, and M.G. Yuan, A Predicting Method of Welding Residual Stress Using Source of Residual Stress (Report I), Trans. JWRI, 1989, 18(2), p 135–141

Y. Ueda and M.G. Yuan, Prediction of Residual Stresses in Butt-Welded Plates Using Inherent Strains, J. Mater. Process. Technol., 1993, 115(8), p 417–423

M.G. Yuan and Y. Ueda, Prediction of Residual Stresses in Welded T- and I-Joints Using Inherent Strains, J. Eng. Mater. Technol., 1996, 118(4), p 229–234

J.C. Wang, S. Rashed, H. Murakaw, and Y. Luo, Numerical Prediction and Mitigation of Out-of-Plane Welding Distortion in Ship Panel Structure by Elastic FE Analysis, Mar. Struct., 2013, 34, p 135–155

H.S. Mun and S.I. Seo, Welding Strain Analysis of Friction Stir-Welded Aluminum Alloy Structures Using Inherent Strain-Based Equivalent Loads, J. Mech. Sci. Technol., 2013, 27(9), p 2775–2782

J.J. Xu, L.G. Chen, J.H. Wang, and C.Z. Ni, Prediction of Welding Distortion in Multipass Girth-Butt Welded Pipes of Different Wall Thickness, Int. J. Adv. Manuf. Technol., 2008, 35, p 987–993

P. Biswas, N.R. Mandal, and S. Das, Prediction of Welding Deformations of Large Stiffened Panels Using Average Plastic Strain Method, Sci. Technol. Weld. Join., 2011, 16(3), p 227–231

D. Deng, H. Murakawa, and N. Ma, Predicting Welding Deformation in Thin Plate Panel Structure by Means of Inherent Strain and Interface Element, Sci. Technol. Weld. Join., 2012, 17(1), p 13–21

H. Murakawa, N. Ma, and H. Huang, Iterative Substructure Method Employing Concept of Inherent Strain for Large-Scale Welding Problems, Weld World, 2015, 59, p 53–63

W. Liang and H. Murakawa, An Inverse Analysis Method to Estimate Inherent Deformations in Thin Plate Welded Joints, Mater. Des., 2012, 40, p 190–198

Y. Ueda and T. Yamakawa, Analysis of Thermal Elastic-Plastic Stress and Strain During Welding by Finite Element Method, Trans. JWRI, 1971, 2, p 90–100

D. Deng and S. Kiyoshim, Numerical Simulation of Residual Stresses Induced by Laser Beam Welding in a SUS316 Stainless Steel Pipe with Considering Initial Residual Stress Influences, Nucl. Eng. Des., 2010, 240, p 688–696

Y.Z. Li, K.Y. Wang, Y.J. Jin, M.J. Xu, and H. Lu, Prediction of Welding Deformation in Stiffened Structure by Introducing Thermo-mechanical Interface Element, J. Mater. Process. Technol., 2015, 216, p 440–446

Z. Zeng, X.B. Li, Y.G. Miao, G. Wu, and Z.J. Zhao, Numerical and Experiment Analysis of Residual Stress on Magnesium Alloy and Steel Butt Joint by Hybrid Laser-TIG Welding, Comput. Mater. Sci., 2011, 50, p 1763–1769

J.U. Park and H.W. Lee, Effects of Initial Condition of Steel Plate on Welding Deformation and Residual Stress Due to Welding, J. Mech. Sci. Technol., 2007, 21, p 426–435

N. Ma, H. Huang, and H. Murakaw, Effect of Jig Constraint Position and Pitch on Welding Deformation, J. Mater. Process. Technol., 2015, 221, p 154–162

H. Long, D. Gery, A. Carlier, and P.G. Maropoulos, Prediction of Welding Distortion in Butt Joint of Thin Plates, Mater. Des., 2009, 30, p 4126–4135

J.C. Wang, M. Shibahara, X.D. Zhang, and H. Murakaw, Investigation on Twisting Distortion of Thin Plate Stiffened Structure Under Welding, J. Mater. Process. Technol., 2012, 212, p 1705–1715

C. Heinze, C. Schwenk, and M. Rethmeier, Numerical Calculation of Residual Stress Development of Multi-pass Gas Metal Arc Welding, J. Constr. Steel. Res., 2012, 72, p 12–19

H. Serizawa, S. Nakamura, K. Kanbe, Y. Fujita, S. Asai, and H. Murakawa, Numerical Analysis of Deformation in Multi-pass Circumferential TIG Welding with Narrow Gap, Weld World, 2013, 57, p 615–623

M. Peric, D. Stamenkovic, and V. Milkovic, Comparison of Residual Stresses in Butt-Welded Plates Using Software Packages Abaqus and Ansys, Sci. Tech. Rev., 2010, 60(3–4), p 22–26

M. Peric, Z. Tonkovic, A. Rodic, M. Surjak, I. Garasic, I. Boras, and S. Svaic, Numerical Analysis and Experimental Investigation of Welding Residual Stresses and Distortions in a T-joint Fillet Weld, Mater. Des., 2014, 53, p 1052–1063

M. Benedetti, V. Fontanari, and C. Santus, Crack Growth Resistance of MAG Butt-Welded Joints of S355JR Construction Steel, Eng. Fract. Mech., 2013, 108, p 305–315

J. Goldak, A. Chakravarti, and M. Bibby, A New Finite Element Model for Welding Heat Sources, Metall. Trans. B, 1984, 15, p 299–305

B. Brickstad and B.L. Josefson, A Parametric Study of Residual Stresses in Multi-pass Butt-Welded Stainless Steel Pipes, Int. J. Pressure Vessels Pip., 1998, 75, p 1–25

W. Liu, J. Ma, S. Liu, and R. Kovacevic, Experimental and Numerical Investigation of Laser Hot Wire Welding, Int. J. Adv. Manuf. Technol., 2015, 78, p p1485–p1499

W. Liu, J. Ma, F. Kong, S. Liu, and R. Kovacevic, Numerical Modeling and Experimental Verification of Residual Stress in Autogenous Laser Welding of High-Strength Steel, Lasers Manuf. Mater. Process., 2015, 2, p 24–42

T.L. Teng and P.H. Chang, Three-Dimensional Thermo Mechanical Analysis of Circumferentially Welded Thin-Walled Pipes, Int. J. Pressure Vessels Pip., 1998, 75, p 237–247

T. Hong, J.Y. Ooi, and B.A. Shaw, A Numerical Study of the Residual Stress Pattern from Single Shot Impacting on a Metallic Component, Adv. Eng. Softw., 2008, 39, p 743–756

O. Toshinari, O. Takayoshi, and M. Fumikazu, UV Radiation Thermometry of TIG Weld Pool-Development of UV Radiation Thermometry (Report 1), Q. J. Jpn. Weld. Soc., 2004, 22(1), p 21–26

Y. Rong, Y. Huang, G. Zhang, Y. Chang, and X. Shao, Prediction of Angular Distortion in No Gap Butt Joint Using BPNN and Inherent Strain Considering the Actual Bead Geometry, Int. J. Adv. Manuf. Technol. doi:10.1007/s00170-015-8102-2

Acknowledgments

This research is supported by the National Basic Research Program of China (973 Program, No. 2014CB046703) and the Fundamental Research Funds for the Central Universities (HUST, No. 2014QN016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rong, Y., Zhang, G. & Huang, Y. Study of Welding Distortion and Residual Stress Considering Nonlinear Yield Stress Curves and Multi-constraint Equations. J. of Materi Eng and Perform 25, 4484–4494 (2016). https://doi.org/10.1007/s11665-016-2259-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2259-1