Abstract

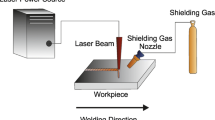

Laser Beam Welding (LBW) is an advanced process to join materials with a laser beam of high energy density. LBW is especially suitable to join titanium alloys, as it allows high localization and low size of the melting pool, reducing considerably the energy of the process, in comparison with other welding technologies. Among the two widely known welding regimes, conduction and keyhole, the former is claimed to be a viable alternative to keyhole, mainly because it is a very stable process, provides high-quality welds free of defects, and involves lower laser cost. In the present work, a Finite Element Method (FEM) has been developed to simulate the LBW of Ti6Al4V alloy under conduction regime. The “Goldak double ellipsoid model” has been taken for the first time to simulate this LBW conduction process. In order to refine and validate the model, experimental conduction welding tests were performed on Ti6Al4V pieces with a high-power diode laser. Microstructural analyses and hardness measurements were also performed on the laser weld beads to identify the generated phases. Distortion and residual stresses were also obtained from the FEM simulations. An excellent agreement between the simulation and experimental results was found regarding the bead morphology and phase transformations.

Similar content being viewed by others

References

S. Katayama, Chapter 1 Introduction: Fundamentals of Laser Welding, Handbook of Laser Welding Technologies. Woodhead Publishing Series in Electronic and Optical Materials No. 41, S. Katayama, Ed., Osaka University, Osaka, 2013,

C. Bertrand, O. Laplanche, J.P. Rocca, Y. Le Petitcorps, and S. Nammour, Effect of the Combination of Different Welding Parameters on Melting Characteristics of Grade 1 Titanium with a Pulsed Nd–Yag Laser, Lasers Med. Sci., 2007, 22, p 237–244

J.M. Sanchez-Amaya, M.R. Amaya Vázquez, and F.J. Botana, Chapter 8: Laser Welding of Light Metal Alloys: Aluminium and Titanium Alloys, Handbook of Laser Welding Technologies. Woodhead Publishing Series in Electronic and Optical Materials No. 41, S. Katayama, Ed., Osaka University, Japan, 2013,

J.M. Sánchez-Amaya, M.R. Amaya-Vázquez, L. González-Rovira, M. Botana-Galvín, and F.J. Botana, Influence of Surface Pre-treatments on Laser Welding of Ti6Al4V Alloy, J. Mater. Eng. Perform., 2014, 23(5), p 1568–1575

A. Costa, R. Miranda, L. Quintino, and D. Yapp, Analysis of Beam Material Interaction in Welding of Titanium with Fiber Lasers, Mater. Manuf. Process., 2007, 22, p 798–803

G. Lütjering and J.C. Williams, Titanium, 2nd ed., Springer, New York, 2007, p 16

J.F. Ready and D.F. Farson, LIA Handbook of Laser Materials Processing, Laser Institute of America, Orlando, 2001

M. Bass, Laser Materials Processing, Elsevier, New York, 1983

M.S.F., Lima, R. Riva, A.C. De Oliveira, and G.R. Siqueira, Laser Beam Welding Aerospace Aluminum Using Fiber Lasers, in Proceedings of SPIE—The International Society for Optical Engineering, Lisbon, 2009

A.G. Paleocrassas and J.F. Tu, Inherent Instability Investigation for Low Speed Laser Welding of Aluminum Using a Single-Mode Fiber Laser, J. Mater. Process. Technol., 2010, 210(10), p 1411–1418

I. Eriksson, and A.F.H. Kaplan, Evaluation of Laser Weld Monitoring—A Case Study, in ICALEO 2009—28th International Congress on Applications of Lasers and Electro-Optics, Congress Proceedings. Orlando, 2009

L. Quintino and E. Assunçao, Chapter 6: Conduction Laser Welding, Handbook of Laser Welding Technologies. Woodhead Publishing Series in Electronic and Optical Materials No. 41, S. Katayama, Ed., Osaka University, Osaka, 2013,

J.C. Ion, Laser Processing of Engineering Materials: Principles, Procedure and Industrial Application, Butterworth-Heinemann, Oxford, 2005

W.M. Steen, Laser Material Processing, 3rd ed., Springer, New York, 2003

S. Nakamura, M. Sakurai, K. Kamimuki, T. Inoue, and Y. Ito, Detection Technique for Transition Between Deep Penetration Mode and Shallow Penetration Mode in CO2 Laser Welding of Metals, J. Phys. D Appl. Phys., 2000, 33(22), p 2941–2948

P. Okon, G. Dearden, K. Watkins, M. Sharp, and P. French, Laser Welding of Aluminium Alloy 5083, in ICALEO 2002—21st International Congress on Applications of Laser and Electro-Optics, Congress Proceedings, Scottsdale, 2002

J.H. Cho, D.F. Farson, J.O. Milewski, and K.J. Hollis, Weld Pool Flows During Initial Stages of Keyhole Formation in Laser Welding, J. Phys. D Appl. Phys., 2009, 42, p 175502

H. Du, L. Hu, J. Liu, and X. Hu, A Study on the Metal Flow in Full Penetration Laser Beam Welding for Titanium Alloy, Comput. Mater. Sci., 2004, 29, p 419–427

M. Azizpour, M. Ghoreishi, and A. Khorram, Numerical Simulation of Laser Beam Welding of Ti6Al4V Sheet, J. Comput. Appl. Res. Mech. Eng. (JCARME), 2015, 4(2), p 145–154

S.A. Tsirkas, P. Papanikos, and Th. Kermanidis, Numerical Simulation of the Laser Welding Process in Butt-Joint Specimens, J. Mater. Process. Technol., 2003, 134(1), p 59–69

K.N. Lankalapalli, J.F. Tu, and M. Gatner, A Model for Estimating Penetration Depth of Laser Welding Processes, J. Phys. D Appl. Phys., 1996, 29(27), p 197–214

K. Williams, Development of Laser Welding Theory with Correlation to Experimental Welding Data, Laser Eng., 1999, 8(3), p 197–214

M.R. Amaya-Vázquez, J.M. Sánchez-Amaya, Z. Boukha, and F.J. Botana, Microstructure, Microhardness and Corrosion Resistance of Remelted TiG2 and Ti6Al4V by a High Power Diode Laser, Corros. Sci., 2012, 56, p 36–48

J.M. Sánchez-Amaya, T. Delgado, J.J. De Damborenea, V. López, and F.J. Botana, Laser Welding of AA 5083 Samples by High Power Diode Laser, Sci. Technol. Weld. Join., 2009, 14(1), p 78–86

J.M. Sánchez-Amaya, T. Delgado, L. González-Rovira, and F.J. Botana, Laser Welding of Aluminium Alloys 5083 and 6082 Under Conduction Regime, Appl. Surf. Sci., 2009, 255(23), p 9512–9521

T.Y. Kuo and H.C. Lin, Effects of Pulse Level of Nd-YAG Laser on Tensile Properties and Formability of Laser Weldments in Automotive Aluminum Alloys, Mat. Sci. Eng. A Struct., 2006, 416, p 281–289

J. Goldak, A. Chakravarti, and M. Bibby, A New Finite Element Model for Welding Heat Sources, Metall. Trans., 1984, 15B, p 299–305

S.K. Bate, R. Charles, and A. Warren, Finite Element Analysis of a Single Bead-On-Plate Specimen Using SYSWELD, Int. J. Press. Vessels Pip., 2009, 86, p 73–78

E. Akman, A. Demir, T. Canel, and T. Sınmazcelik, Laser Welding of Ti6Al4V Titanium Alloys, J. Mater. Process. Tech., 2009, 209, p 3705–3713

X. Cao and M. Jahazi, Effect of Welding Speed on Butt Joint Quality of Ti–6Al–4V Alloy Welded Using a High-Power Nd:YAG Laser, Opt. Laser. Eng., 2009, 47, p 1231–1241

T. Ahmed and H.J. Rack, Phase Transformations During Cooling in α + β Titanium Alloys, Mater. Sci. Eng. A, 1998, 243, p 206–211

A. Squillace, U. Prisco, S. Ciliberto, and A. Astarita, Effect of Welding Parameters on Morphology and Mechanical Properties of Ti–6Al–4V Laser Beam Welded Butt Joints, J. Mater. Process. Technol., 2012, 212, p 427–436

Acknowledgments

The present work has been financially supported by Andalusian Regional Government (Junta de Andalucía) (Project SOLDATIA, Ref. TEP 6180), CDTI (Centro para el Desarrollo Tecnológico Industrial, Spain), and FEDER Program, under COSSTA Project (FEDER- Innterconecta 2011-2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited submission to JMEP selected from presentations at the Symposium “Joining Technologies,” belonging to the Topic “Joining and Interfaces” at the European Congress and Exhibition on Advanced Materials and Processes (EUROMAT 2015), held September 20-24, 2015, in Warsaw, Poland, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Churiaque, C., Amaya-Vazquez, M.R., Botana, F.J. et al. FEM Simulation and Experimental Validation of LBW Under Conduction Regime of Ti6Al4V Alloy. J. of Materi Eng and Perform 25, 3260–3269 (2016). https://doi.org/10.1007/s11665-016-2214-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2214-1