Abstract

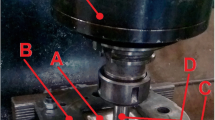

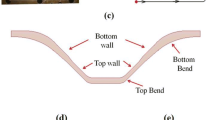

This research is aimed at enhancing the poor room temperature formability of heat-treatable aluminum alloy AA2024-T3, without deterioration of its post-forming properties. For this purpose, the influences of different heat-treatment conditions as well as warm forming on the single point incremental forming formability and post-forming properties of this material were investigated. Thermal pre-treatments were consisting of annealing (O-temper), solution treating and quenching (W-temper), and solution heat treating, quenching, and then cold working (T-temper). The formability results as well as forming forces of pre-heat-treated sheets were compared to those of the warm forming process results carried out using a laser-assisted single point incremental forming (LASPIF) setup. The post-forming properties of SPIF-formed parts were analyzed by hardness testing. The maximum forming angles of the blank formed under O-temper and W-temper conditions showed, respectively, 41 and 32% increases compared to the one under T-temper condition. LASPIF forming of this material at a temperature of about 360 °C resulted in 41% improvement in the maximum forming angle with respect to parts formed at room temperature from the T-temper sheet. The hardness of the material reduced significantly after annealing, while SPIF parts formed from W-temper blanks and under LASPIF condition regained their hardness after natural aging. The fracture surface characteristics of the failed parts showed that voids nucleate at the interface between intermetallic particles and matrix, and a dimple rupture fracture mode was identified under all heat-treatment conditions. Under O-temper condition, due to precipitation of particles along the grain boundary, an intergranular dimple rupture was observed. Finally, Energy dispersive x-ray (EDX) and electron backscattered diffraction (EBSD) were used to investigate the possible effects of the heat treatment and the deformation on the changes in the composition of intermetallic and second-phase particles, grain size, and texture.

Similar content being viewed by others

References

P.J. Bolt, N.A.P.M. Lamboo, P.J.C.M. Rozier, Feasibility of Warm Drawing of Aluminium Products, J. Mater. Process. Technol. 2001, 115(1), p 118–121.

L. Wang, M. Strangwood, D. Balint, J. Lin, and T.A. Dean, Formability and Failure Mechanisms of AA2024 Under Hot Forming Conditions, Mater. Sci. Eng. A Struct., 2011, 528(6), p 2648–2656

H. Wang, Y.B. Luo, P. Friedman, M.H. Chen, and L. Gao, Warm Forming Behavior of High Strength Aluminum Alloy AA7075, Trans. Nonferr. Metal. Soc. China, 2012, 22(1), p 1–7

P. Kulkarni and S. Prabhakar, Influence of the Effect of Strain Rates on Springback in Aluminum 2024 (ISO AlCuMg1), The 4th European LS-DYNA, May 22-23, 2013 (Ulm(Germany)), p 27–34.

M. O’Donnell, A.G. Leacock, D. Banabic, D. Brown, and R.J. McMurray, The Effect of Pre-Strain and Solution Heat Treatment on the Formability of a 2024 Aluminium Alloy, Int J Mater Form., 2008, 1(1), p 257–260

D. He, X. Li, D. Li, and W. Yang, Process Design for Multi-stage Stretch Forming of Aluminium Alloy Aircraft Skin, Trans. Nonferr. Met. Soc. China, 2010, 20(6), p 1053–1058

J. Jeswiet, F. Micari, G. Hirt, A. Bramley, J. Duflou, and J. Allwood, Asymmetric Single Point Incremental Forming of Sheet Metal, CIRP Ann. Manuf. Technol., 2005, 54(2), p 88–114

J.R. Duflou, B. Callebaut, J. Verbert, and H. De Baerdemaeker, Laser Assisted Incremental Forming: Formability and Accuracy Improvement, CIRP Ann. Manuf. Technol., 2007, 56(1), p 273–276

ASM International, Heat Treating of Aluminum Alloys. ASM Handbook Heat treating, Vol. 4, ASM International, Materials Park, 1991, p 1861–1960

R.C. Dorward, Forming Characteristics of Coarse and Fine-Grained AA 2024 Aluminum Alloy Sheet, J. Mater. Eng. Perform., 1994, 3(1), p 115–121

G. Ambrogio, L. Filice, and G.L. Manco, Warm Incremental Forming of Magnesium Alloy AZ31, CIRP Ann. Manuf. Technol., 2008, 57(1), p 257–260

L. Galdos, E.S.D. Argandoña, I. Ulacia, and G. Arruebarrena, Warm Incremental Forming of Magnesium Alloys Using Hot Fluid as Heating Media, Key Eng. Mater., 2012, 504–506, p 815–820.

G. Palumbo and M. Brandizzi, Experimental Investigations on the Single Point Incremental Forming of a Titanium Alloy Component Combining Static Heating with High Tool Rotation Speed, Mater. Design, 2012, 40(6), p 43–51

A. Mohammadi, H. Vanhove, A. Van Bael, and J.R. Duflou, Formability Enhancement in Incremental Forming for an Automotive Aluminium Alloy Using Laser Assisted Incremental Forming, Key Eng. Mater., 2015, 639, p 195–202

ASTM International, Standard Practice for Measuring and Compensating for Emissivity Using Infrared Imaging Radiometers, ASTM E1933-14, ASTM International, West Conshohocken, PA, 2014.

F. Vollertsen, Laserstrahlumformen, Lasergestützte Formgebung, Verfahren, Mechanismen, Modellierung, Meisenbach, Bamberg, 1996. (in German)

J.R. Davis, JRD Associates, ASMIH Committee, Aluminum and Aluminum Alloys, ASM International, Materials Park, 1993.

M. Kapustová and M. Martinkovic, Influence of Temperature on Plasticity and Workability of Aluminum Alloys, Annals of the Faculty of Engineering Hunedoara, Int. J. Eng., 2012, 10(2), p 223–226

W. Ostwald, Lehrbuch der Allgemeinen Chemie (1896), Vol. 2, Part 1, Leipzig, Germany, 1896

E. Orowan and Faraday S, Symposium on Internal Stresses in Metals and Alloys, Inst. Met., 1948, p 451.

T. Gladman, Precipitation Hardening in Metals, Mater. Sci. Tech., 1999, 15(1), p 30–36

C.F. Guzmán, J. Gu, J.R. Duflou, H. Vanhove, P. Flores, and A.M. Habraken, Study of the Geometrical Inaccuracy on a SPIF Two-Slope Pyramid by Finite Element Simulations, Int. J. Solids Struct., 2012, 49(25), p 3594–3604

A. Mohammadi, H. Vanhove, A. Van Bael, M. Seefeldt, and J.R. Duflou, The Effects of Laser Radiation on the Residual Stress Levels of Single Point Incrementally Formed (SPIF) Parts, April 9-10, 2014, Bremen, Germany, Proceedings of the 4th International Workshop on Thermal Forming and Welding Distortion (IWOTE’14), p 83–92.

A. Mohammadi, H. Vanhove, A. Van Bael, and J.R. Duflou, Bending Properties of Locally Laser Heat Treated AA2024-T3 Aluminium Alloy, Phys. Proc., 2012, 39, p 257–264

E.O. Hall, The Deformation and Ageing of Mild Steel: II Characteristics of the Lüders Deformation, Proc. Phys. Soc. Sect. B., 1951, 64(9), p 742.

R.G. Buchheit, R.R. Grant, R.F. Hlava, B. McKenzie, and G.L. Zender, Local Dissolution Phenomena Associated with S Phase (Al2CuMg) Particles in Aluminium Alloy 2024-T3, J. Electrochem. Soc., 1997, 144(8), p 2621–2628

L. Priester, Precipitation at Grain Boundaries, Grain Boundaries: From Theory to Engineering, Vol 172, Springer, Netherlands, 2013, p 217–240.

S. He, J. Gu, H. Sol, A. Van Bael, P. van Houtte, Y. Tunckol, and J.R. Duflou, Determination of Strain in Incremental Sheet Forming Process, Key Eng. Mater., 2007, 344, p 503–510

P. Flores, L. Duchêne, C. Bouffioux, T. Lelotte, C. Henrard, N. Pernin, A. Van Bael, S. He, J. Duflou, and A.M. Habraken, Model Identification and FE Simulations: Effect of Different Yield Loci and Hardening Laws in Sheet Forming, Int. J. Plast., 2007, 23(9), p 420–449

A. Mohammadi, H. Vanhove, A. Van Bael, and J.R. Duflou, Towards Accuracy Improvement in Single Point Incremental Forming of Shallow Parts Formed Under Laser Assisted Conditions, Int. J. Mater. Form., 2014, p 1–13.

M.B. Silva, M. Skjødt, P.A.F. Martins, and N. Bay, Revisiting the Fundamentals of Single Point Incremental Forming by Means of Membrane Analysis, Int. J. Mach. Tool. Manu., 2008, 48(1), p 73–83

P.F. Thomason, Three-Dimensional Models for the Plastic Limit-Loads at Incipient Failure of the Intervoid Matrix in Ductile Porous Solids, Acta. Metall., 1985, 33(6), p 1079–1085

J.W. Martin, Fracture Behavior of Aged Alloys, Precipitation Hardening (Second Edition), J.W. Martin, Ed., Butterworth-Heinemann, Oxford, 1998, p 126–170

W.M. Garrison and N.R. Moody, Ductile Fracture, J. Phys. Chem. Solids, 1987, 48(11), p 1035–1074

R. Abbaschian and R. Reed-Hill, Physical Metallurgy Principles, SI Version, Cengage Learning, Boston, 2010, p 700–706

Acknowledgments

The authors would like to acknowledge the financial support from the Fonds Wetenschappelijk Onderzoek-Vlaanderen (FWO) through Project G.0B44.13.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohammadi, A., Qin, L., Vanhove, H. et al. Single Point Incremental Forming of an Aged AL-Cu-Mg Alloy: Influence of Pre-heat Treatment and Warm Forming. J. of Materi Eng and Perform 25, 2478–2488 (2016). https://doi.org/10.1007/s11665-016-2055-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2055-y