Abstract

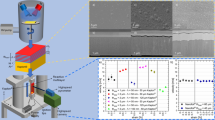

We have studied the dissolution process of Ni into liquid Al in Ni-Al multilayer nanofilms by means of molecular dynamics simulations. The elemental mechanisms underlying the dissolution process were described and found to be diffusion-limited. The subsequent evolution leading to intermetallic compound formation was analyzed and interpreted on the basis of classical nucleation theory. A better understanding of the microscopic behavior of Ni-Al reactive multilayer foils, which was essential for their use in joining applications, was obtained.

Similar content being viewed by others

References

T.W. Barbee, and T. Weihs, Ignitable Heterogeneous Stratified Structure for the Propagating of an Internal Exothermic Chemical Reaction Along an Expanding Wavefront and Method of Making Same, U.S. Patent No. 5538795, July 23 (1996)

A. Duckham, S.J. Spey, J. Wang, M.E. Reiss, T.P. Weihs, E. Besnoin, and O.M. Knio, Reactive Nanostructured Foil Used as a Heat Source for Joining Titanium, J. Appl. Phys., 2004, 96, p 2336–2342

S. Simoes, F. Viana, M. Kocak, A.S. Ramos, M.T. Vieira, and M.F. Vieira, Microstructure of Reaction Zone Formed During Diffusion Bonding of TiAl with Ni/Al Multilayer, J. Mater. Eng. Perform., 2012, 21, p 678–682

R. Grieseler, T. Welker, J. Müller, and P. Schaaf, Bonding of Low Temperature Co-fired Ceramics to Copper and to Ceramic Blocks by Reactive Aluminum/Nickel Multilayers, Phys. Status Solidi, 2002, 209, p 512–518

B. Lehmert, J. Janczak-Rusch, G. Pigozzi, P. Zuraw, F. La Mattina, L. Wojarski, W. Tillmann, and L.P.H. Jeurgens, Copper-Based Nanostructured Coatings for Low-Temperature Brazing Applications, Mater. Trans., 2015, 56, p 1015–1018

J. Braeuer, J. Besser, M. Wiemer, and T. Gessner, A Novel Technique for MEMS Packaging: Reactive Bonding with Integrated Material Systems, Sens. Actuators A Phys., 2012, 188, p 212–219

U.K. Stolz, I. Arpshofen, and F. Sommer, Determination of the Enthalpy of Mixing of Liquid Alloys Using a High-Temperature Mixing Calorimeter, J. Phase Equilib., 1993, 14, p 473–478

K.V. Grigorovich and A.S. Krylov, Thermodynamics of Liquid Al-Ni Alloys, Thermochim. Acta, 1998, 314, p 255–263

S. Plimpton, Fast Parallel Algorithms for Short-Range Molecular Dynamics, J. Comp. Phys., 1995, 117(1). 1–19 http://lammps.sandia.gov/

G.P. Purja and Y. Mishin, Development of an Interatomic Potential for the Ni-Al System, Philos. Mag., 2009, 89, p 3245–3267

T.B. Massalski, J.L. Murray, L.H. Bennett, and H. Baker, Binary Alloy Phase Diagrams, American Society for Metals, Metals Park, 1986, p 628–629

W. Huang and Y.A. Chang, A Thermodynamic Analysis of the Ni-Al System, Intermetallics, 1998, 6, p 487–498

V. Turlo, O. Politano, and F. Baras, Dissolution Process at Solid/Liquid Interface in Nanometric Metallic Multilayers: Molecular Dynamics Simulations Versus Diffusion Modeling, Acta Mater., 2015, 99, p 363–372

G.J. Ackland and A.P. Jones, Applications of Local Crystal Structure Measures in Experiment and Simulation, Phys. Rev. B, 2006, 73, p 054104

G. Kaptay, J. Janczak-Rusch, G. Pigozzi, and L.P.H. Jeurgens, Theoretical Analysis of Melting Point Depression of Pure Metals in Different Initial Configurations, J. Mater. Eng. Perform., 2014, 23, p 1600–1607

D.A. Porter and K.E. Easterling, Phase Transformations in Metals and Alloys, 2d ed., Chapman & Hall, London, 1992, p 191

Acknowledgment

The use of computational facilities at the Computing Center of the University of Bourgogne, PSIUN-CCUB, is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Footnote: This article is an invited submission to JMEP selected from presentations at the Symposium “Interface Design and Modelling,” belonging to the Topic “Joining and Interfaces” at the European Congress and Exhibition on Advanced Materials and Processes (EUROMAT 2015), held September 20-24, 2015, in Warsaw, Poland, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Baras, F., Turlo, V. & Politano, O. Dissolution at Interfaces in Layered Solid-Liquid Thin Films: A Key Step in Joining Process. J. of Materi Eng and Perform 25, 3270–3274 (2016). https://doi.org/10.1007/s11665-016-1989-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-1989-4