Abstract

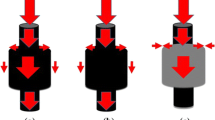

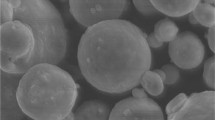

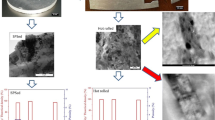

The effects of MgO as a sintering additive, sintering duration, and post-heat treatment on mechanical properties and microstructure of spark plasma-sintered aluminum powders were investigated. The sinterability of aluminum with or without MgO was found to be sensitive to the aluminum average particle size, meaning the amount of native oxide within the raw aluminum powders. The fracture mode changes gradually from a brittle mode (after short SPS), through a mixed brittle-ductile fracture mode (after long SPS), ending with the pure ductile form (short SPS followed by heat treatment). Maxima flexural strength and elongation were found in samples with particles size of about 44 μm and the addition of 2 wt.% MgO after short SPS process followed by an additional heat treatment. The addition of MgO may contribute to perforation of the aluminum native oxide and enhance aluminum diffusion during the heat treatment.

Similar content being viewed by others

References

W.S. Miller, L. Zhuang, J. Bottema, A.J. Wittebrood, P. De Smet, A. Haszler, and A. Vieregge, Recent Development in Aluminium Alloys for the Automotive Industry, Mater. Sci. Eng., A, 2000, 280(1), p 37–49

T. Dursun and C. Soutis, Recent Developments in Advanced Aircraft Aluminium Alloys, Mater. Des., 2014, 56, p 862–871

A. Heinz, A. Haszler, C. Keidel, S. Moldenhauer, R. Benedictus, and W.S. Miller, Recent Development in Aluminium Alloys for Aerospace Applications, Mater. Sci. Eng., A, 2000, 280(1), p 102–107

G.B. Schaffer, T.B. Sercombe, and R.N. Lumley, Liquid Phase Sintering of Aluminium Alloys, Mater. Chem. Phys., 2001, 67(1-3), p 85–91

A. Gokce and F. Findik, Mechanical and Physical Properties of Sintered Aluminium Powders, J. Achiev. Mater. Manuf. Eng., 2008, 30(2), p 157–164

G. Xie, O. Ohashi, T. Sato, N. Yamaguchi, M. Song, K. Mitsuishi, and K. Furuya, Effect of Mg on the Sintering of Al-Mg Alloy Powders by Pulse Electric-Current Sintering Process, Mater. Trans., 2004, 45(3), p 904–909

N. Showaiter and M. Youseffi, Compaction, Sintering and Mechanical Properties of Elemental 6061 Al Powder with and Without Sintering Aids, Mater. Des., 2008, 29(4), p 752–762

I.A. MacAskill, R.L. Hexemer, Jr., I.W. Donaldson, and D.P. Bishop, Effects of Magnesium, Tin and Nitrogen on the Sintering Response of Aluminum Powder, J. Mater. Process. Technol., 2010, 10(15), p 2252–2260

G. Xie, O. Ohashi, M. Song, K. Mitsuishi, and K. Furuya, Reduction Mechanism of Surface Oxide Films and Characterization of Formations on Pulse Electric-Current Sintered Al-Mg Alloy Powders, App. Surf. Sci., 2005, 241(1-2), p 102–106

G.Q. Xie, O. Ohashi, N. Yamaguchi, M. Song, K. Furuya, and T. Noda, TEM Observation of Interfaces Between Particles in Al-Mg Alloy Powder Compacts Prepared by Pulse Electric Current Sintering, Mater. Trans., 2002, 43(9), p 2177–2180

R.N. Lumley, T.B. Sercombe, and G.B. Schaffer, Surface Oxide and the Role of Magnesium During the Sintering of Aluminum, Metall. Mater. Trans. A, 1999, 30(2), p 457–463

A. Kimura, K. Kondoh, M. Shibata, and R. Watanabe, Breakaway Behavior of Surface Oxide Film on Aluminum-Silicon-Magnesium Alloy Powder Particles at High Temperature in a Vacuum, Mater. Trans., 2001, 42(7), p 1373–1379

A. Kimura, M. Shibata, K. Kondoh, Y. Takeda, M. Katayama, T. Kanie, and H. Takada, Reduction Mechanism of Surface Oxide in Aluminum Alloy Powders Containing Magnesium Studied by x-ray Photoelectron Spectroscopy Using Synchrotron Radiation, Appl. Phys. Lett., 1997, 70(26), p 3615–3617

R. Orru, R. Licheri, A.M. Locci, A. Cincotti, and G. Cao, Consolidation/Synthesis of Materials by Electric Current Activated/Assisted Sintering, Mater. Sci. Eng., R, 2009, 63(4-6), p 127–287

G. Xie, O. Ohashi, M. Song, K. Furuya, and T. Noda, Behavior of Oxide Film at the Interface Between Particles in Sintered Al Powders by Pulse Electric-Current Sintering, Metall. Mater. Trans. A, 2003, 34A(3), p 699–703

H. Sieber, D. Hesse, X. Pan, S. Senz, and J. Heydenreich, TEM Investigations of Spinel-Forming Solid State Reactions: Reaction Mechanism, Film Orientation, and Interface Structure During MgAl2O4 Formation on MgO (001) and Al2O3 (11.2) Single Crystal Substrates, Z. Anorg. Allg. Chem., 1996, 622(10), p 1658–1666

I. Rosenthal, E. Tiferet, M. Ganor, and A. Stern, Selective Laser Melting Additive Manufacturing: AlSi10 Mg Powder Characterization, Ann. Duna. Univ. Galati Fascicle XII, Weld. Equip. Technol., 2014, 25, p 35–40

M. Zadra, F. Casari, L. Girardini, and A. Molinari, Spark Plasma Sintering of Pure Aluminium Powder: Mechanical Properties and Fracture Analysis, Powder Metall., 2007, 50(1), p 40–45

X.P. Li, M. Yan, H. Imai, K. Kondoh, G.B. Schaffer, and M. Qian, The Critical Role of Heating Rate in Enabling the Removal of Surface Oxide Films During Spark Plasma Sintering of Al-Based Bulk Metallic Glass Powder, J. Non-Cryst. Sol., 2013, 375(1-2), p 95–98

M.A. Trunov, M. Schoenitz, X. Zhu, and E.L. Dreizin, Effect of Polymorphic Phase Transformations in Al2O3 Film on Oxidation Kinetics of Aluminum Powders, Combust. Flame, 2005, 140(4), p 310–318

M. Omori, Sintering, Consolidation, Reaction and Crystal Growth by the Spark Plasma System (SPS), Mater. Sci. Eng., A, 2000, 287(2), p 183–188

Acknowledgment

This work was partially supported by the Pazy Foundation (grant 249/15) and the FP7-PEOPLE-2012-CIG (Grant 321838-EEEF-GBE-CNS).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ben-Haroush, M., Dikovsky, G., Kalabukhov, S. et al. Spark Plasma Sintering of MgO-Strengthened Aluminum. J. of Materi Eng and Perform 25, 648–655 (2016). https://doi.org/10.1007/s11665-015-1866-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1866-6