Abstract

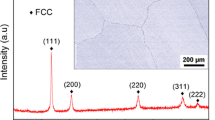

Mechanical properties of cylindrical bi-phasic high-entropy alloy Cu29Zr32Ti15Al5Ni19 (3 mm in diameter) were characterized by nanoindentation test in each phase. The results show that the constituent FCC phase is of low nanohardness (2.35 GPa) and modulus (60.9 GPa), while another constituent phase in the alloy, the HCP phase, shows much higher nanohardness (6.5 GPa) and modulus (115.3 GPa). Creep occurs in both phases during the indentation.

Similar content being viewed by others

References

Z.J. Wang, S. Guo, Q. Wang, Z.Y. Liu, J.C. Wang, Y. Yang, and C.T. Liu, Nanoindentation characterized initial creep behavior of a high-entropy-based alloy CoFeNi, Intermetallics, 2014, 53, p 183–186

C. Sajith Babu, K. Sivaprasad, V. Muthupandi, and J.A. Szpunar, Characterization of nanocrystalline AlCoCrCuNiFeZn high entropy alloy produced by mechanical alloying, Procedia Mater. Sci., 2014, 5, p 1020–1026

X. Yang and Y. Zhang, Prediction of high-entropy stabilized solid-solution in multi-component alloys, Mater. Chem. Phys., 2012, 132, p 233–238

Y. Sun, G.F. Zhao, X.Y. Wen, J.W. Qiao, and F.Q. Yang, Nanoindentation deformation of a bi-phase AlCrCuFeNi2 alloy, J. Alloys Compd., 2014, 608, p 49–53

M. Vaidy, S. Armugam, S. Kashyap, and B.S. Murty, Amorphization in equiatomic high entropy alloys, J. Non-Cryst. Solids, 2015, 413, p 8–14

C. Zhu, Z.P. Lu, and T.G. Nieh, Incipient plasticity and dislocation nucleation of FeCoCrNiMn, Acta Mater., 2013, 61, p 2993–3001

Y. Ma, G.J. Peng, D.H. Wen, and T.H. Zhang, Nanoindentation creep behavior in a CoCrFeCuNi high-entropy alloy film with two different structure states, Mater. Sci. Eng. A, 2015, 621, p 111–117

J.L. Wu, Y. Pan, and J.H. Pi, Evaluation of Cu–Zr–Ti–In bulk metallic glasses via nanoindentation, J. Mater. Eng. Perform., 2013, 22, p 2288–2292

A.C. Fischer-Cripps, Nanoindentation, 3rd ed., Springer, New York, 2011

M.J. Cordill, M.S. Lund, J. Parker, C. Leighton, A.K. Nair, D. Farkas, N.R. Moody, and W.W. Gerberich, The Nano-Jackhammer effect in probing near-surface mechanical properties, Int. J. Plast., 2009, 25(p2), p 045–2058

T.H. Zhang, Micro/nanomechanical testing technology, 1st ed., Science Press, Peking, 2013

J.H. Pi, X.C. He, and Z.Z. Wang, Preparation high entropy alloy Cu29Zr32Ti15Al5Ni19 with high glass forming ability, Rare Metal Mater. Eng., 2016, online preview website: http://rmme.ijournal.cn/rmme/ch/reader/view_abstract.aspx?flag=2&file_no=201505150000002&journal_id=rmme#

J.J. Roa, G. Fargas, A. Mateo, and E. Jiménez-Piqué, Dependence of nanoindentation hardness with crystallographic orientation of austenite grains in metastable stainless steels, Mater. Sci. Eng. A, 2015, 645, p 188–195

C. Li and L.C. Zhang, Mechanical behaviour characterisation of silicon and effect of loading rate on pop-in: a nanoindentation study under ultra-low loads, Mater. Sci. Eng. A, 2009, 506, p 125–129

W.H. Li, K. Shin, C.G. Lee, B.C. Wei, T.H. Zhang, and Y.Z. He, The Characterization of creep and time-dependent properties of bulk metallic glasses using nanoindentation, Mater. Sci. Eng. A, 2008, 478, p 371–375

J.L. Hay and G.M. Pharr, Instrumented indentation testing, materials, ASM International, Park, OH, 2000, p 232–243

W.C. Oliver and G.M. Pharr, An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments, J. Mater. Res., 1992, 7(6), p 1564–1583

Y.I. Golovin, Nanoindentation and mechanical properties of solids in submicrovolumes, thin near-surface layers, and films: a review, Phys. Solids State, 2008, 50(2), p 2205–2236

R.D. Dar and Y. Chen, Nanoindentation studies of small-scale martensitic transformations and ductile precipitate effects in dual-phase polycrystalline shape memory alloys, Acta Mater., 2015, 91, p 112–127

K. Xiong and J.F. Gu, Understanding pop-in phenomena in FeNi3 nanoindentation, Intermetallics, 2015, 67, p 111–120

M.R. VanLandingham, Review of instrumented indentation, J. Res. Natl. Inst. Stand. Technol., 2003, 108(4), p 249–265

Acknowledgments

The authors would like to thank for the financial support by the Opening Project of Jiangsu Key Laboratory of Advanced Structural Materials and Application Technology (ASMA201418), Innovation Fund (CKJA201301, CKJB201302) and Dr. Special Found (ZKJ201403) of Nanjing Institute of Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pi, J., Wang, Z., He, X. et al. Nanoindentation Mechanical Properties of a Bi-phase Cu29Zr32Ti15Al5Ni19 Alloy. J. of Materi Eng and Perform 25, 76–82 (2016). https://doi.org/10.1007/s11665-015-1821-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1821-6