Abstract

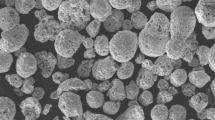

High-velocity oxygen fuel (HVOF) thermal spray, carbide–cermet-based coatings are usually employed in high-temperature erosive and erosive–corrosive environments. Extensive literature is available on high-temperature erosion performance of HVOF coatings under moderate to low particle flux and velocities for application in boiler tubes. This research work presents the characterization and high-temperature erosion behaviour of Cr3C2-25NiCr and WC-10Co-4Cr HVOF-sprayed coatings. Coatings were formulated on the substrate steel of type AISI 304, commonly used for the fabrication of pulverized coal burner nozzles (PCBN). Erosion testing was carried out in high-temperature air-jet erosion tester after simulating the conditions akin to that prevailing in PCBN in the boiler furnace. The coatings were tested for erosion behaviour at different angles and temperatures by freezing other test parameters. Brittle erosion behaviour was depicted in erosion testing, and the coatings couldn’t restrain the erodent attacks to protect the substrate. High particle velocity and high particle flux were attributed to be the reasons of extensive erosive weight loss of the coatings. The surface morphology of the eroded specimens was analysed from back-scattered electron images to depict the probable mechanism of material removal. The coatings were characterized with optical microscopy, SEM-EDS analysis, XRD analysis, micro-hardness testing, porosity measurements, surface roughness testing and bond strength testing. The work was undertaken to investigate the performance of the selected coatings in highly erosive environment, so as to envisage their application in PCBNs for protection against material degradation. The coatings could only sustain in oblique impact erosion at room temperature and depleted fully under all other conditions.

Similar content being viewed by others

References

J.A. Hearley, J.A. Little, and A.J. Sturgeon, The Erosion Behaviour of NiAl Intermetallic Coatings Produced By High Velocity Oxy-Fuel Thermal Spraying, Wear, 1999, 233-235, p 328–333

K.J. Stein, B.S. Schorr, and A.R. Marder, Erosion of Thermal Spray MCr-Cr3C2 Cermet Coatings, Wear, 1999, 224(1), p 153–159

P.J. Hoop and C. Allen, The High Temperature Erosion of Commercial Thermally Sprayed Metallic and Cermet Coatings by Solid Particles, Wear, 1999, 233–235, p 334–341

B.S. Sidhu and S. Prakash, Erosion-Corrosion of Plasma As Sprayed and Laser Remelted Stellite-6 Coatings in a Coal Fired Boiler, Wear, 2006, 260(9–10), p 1035–1044

X.Q. Yu, M. Fan, and Y.S. Sun, The Erosion-Corrosion Behavior of Some Fe3Al-based Alloys at High Temperatures, Wear, 2002, 253(5-6), p 604–609

P. Pekko, Tetrahedral Amorphous Carbon Deposited with the Pulsed Plasma Arc-Discharge Method as a Protective Coating against Solid Impingement Erosion, Diam. Relat. Mater., 2000, 9(8), p 1524–1528

V. Shanov, W. Tabakoff, Erosion Resistance of Coatings for Metal Protection at Elevated Temperatures, Surface and Coatings Technology, Surf. Coat. Technol., 1996, 86-87, Part 1(0), p 88–93

S. Chatterjee and T.K. Pal, Solid Particle Erosion Behaviour of Hardfacing Deposits on Cast Iron-Influence of Deposit Microstructure and Erodent Particles, Wear, 2006, 261(10), p 1069–1079

ASTM-G40-13, Standard Terminology Relating to Wear and Erosion, ASTM International, West Conshohocken, PA, 2013, 03.02, p 1–8

J.B. Cheng, X.B. Liang, Y.X. Chen, Z.H. Wang, and B.S. Xu, High-Temperature Erosion Resistance of FeBSiNb Amorphous Coatings Deposited by Arc Spraying for Boiler Applications, J Therm Spray Tech, 2013, 22(5), p 820–827

M. Kaur, H. Singh, S. Prakash, High-Temperature Behavior of a High-Velocity Oxy-Fuel Sprayed Cr3C2-NiCr Coating, Metall. Mater. Trans. A, 2012, 43A, p 2979–2993

B.Q. Wang and S.W. Lee, Elevated Temperature Erosion of Several Thermal-Sprayed Coatings Under the Simulated Erosion Conditions of In-Bed Tubes in a Fluidized Bed Combustor, Wear, 1997, 203-204, p 580–587

B.Q. Wang and Z.R. Shui, Hot Erosion Behavior of Carbide-Metal Composite Coatings, J. Mater. Process. Technol., 2003, 143-144, p 87–92

A.K. Maiti, N. Mukhopadhyay, and R. Raman, Effect of Adding WC Powder to the Feedstock of WC–Co–Cr based HVOF Coating and its Impact on Erosion and Abrasion Resistance, Surf. Coat. Technol., 2007, 201(18), p 7781–7788

P.K. Jindal and B.S. Sidhu, Degradation of Pulverized Coal Burner Nozzles: A Review, Indian J. Eng. Sci. Technol., 2010, 4(1), p 63–66

P. Bowen, Burner Nozzle for Pulverized Coal, U.S. Patents Ed., 2000, p 1–6

T.E. Bauer, M.E. Bauer, E.C. Bauer, Burner Nozzle Tip for Pulverized Coal and Method for its Production, U.S. Patents Ed., 1974, p 1–19

ASTM-E562-11, Standard Test Method for Determining Volume Fraction by Systematic Manual Point Count, ASM International, 2011, 03.01, p 1–7

ASTM-C633-01, Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings, ASTM International, West Conshohocken, PA, 2001, p 1–7

ASTM-B487-85, Standard Test Method for Measurement of Metal and Oxide Coating Thickness by Microscopical Examination of a Cross Section, ASTM International, West Conshohocken, PA, 2002, p 1–5

L.K. Baldaev, I.F. Arutyunova, and L.N. Dmitrienko, hermal Spray Coatings Deposited by a High-Speed Burner, Chem. Pet. Eng., 2001, 37(9-10), p 487–489

B.Q. Wang, Effect of Alkali Chlorides on Erosion-Corrosion of Cooled Mild Steel and Cr3C2-NiCr Coating, Wear, 1996, 199(2), p 268–274

M. Kaur, H. Singh, and S. Prakash, A Survey of the Literature on the Use of High Velocity Oxy-Fuel Spray Technology for High Temperature Corrosion and Erosion-Corrosion Resistant Coatings, Anti-Corros. Methods Mater., 2008, 55(2), p 86–96

D. Poirier, J.-G. Legoux, and R.S. Lima, Engineering HVOF-Sprayed Cr3C2-NiCr Coatings: The Effect of Particle Morphology and Spraying Parameters on the Microstructure, Properties, and High Temperature Wear Performance, J. Therm. Spray Technol., 2013, 22(2-3), p 280–289

S. Matthews, B. James, and M. Hyland, High Temperature Erosion of Cr3C2-NiCr Thermal Spray Coatings—The Role of Phase Microstructure, Surf. Coat. Technol., 2009, 203(9), p 1144–1153

S. Matthews, B. James, and M. Hyland, The Role of Microstructure in the Mechanism of High Velocity Erosion of Cr3C2-NiCr Thermal Spray Coatings: Part 1—As-Sprayed Coatings, Surf. Coat. Technol., 2009, 203(8), p 1086–1093

B.Q. Wang and Z.R. Shui, The Hot Erosion Behavior of HVOF Chromium Carbide-Metal Cermet Coatings Sprayed with Different Powders, Wear, 2002, 253(5-6), p 550–557

S.J. Matthews, Erosion-Corrosion of Cr3C2-NiCr High Velocity Thermal Spray Coatings,” Ph.D. Thesis Thesis, University of Auckland

R.C. Tucker, Thermal Spray Coatings, ASM Handbook Vol. 5, ASM International, 1994, p 497

S. Matthews, B. James, and M. Hyland, High Temperature Erosion-Oxidation of Cr3C2–NiCr Thermal Spray Coatings under Simulated Turbine Conditions, Corros. Sci., 2013, 70, p 203–211

D. Toma, W. Brandl, and G. Marginean, Wear and Corrosion Behaviour of Thermally Sprayed Cermet Coatings, Surf. Coat. Technol., 2001, 138(2–3), p 149–158

J.M. Guilemany, J.M. Miguel, S. Vizcaíno, C. Lorenzana, J. Delgado, and J. Sánchez, Role of Heat Treatments in the Improvement of the Sliding Wear Properties of Cr3C2–NiCr Coatings, Surf. Coat. Technol., 2002, 157(2–3), p 207–213

J. Yoganandh, S. Natarajan, S.P. Kumaresh Babu, Erosion Behaviour of WC–Co–Cr Thermal Spray Coated Grey Cast Iron under Mining Environment, Trans. Indian Inst. Met., 2013, 66(4), p 437–443

P.H. Shipway, D.G. McCartney, and T. Sudaprasert, Sliding Wear Behaviour of Conventional and Nanostructured HVOF Sprayed WC–Co Coatings, Wear, 2005, 259(7-12), p 820–827

D.A. Stewart, P.H. Shipway, D.G. McCartney, Abrasive Wear Behaviour Of Conventional and Nanocomposite HVOF-Sprayed Wc–Co Coatings, Wear, 1999, 225-229, Part 2(0), p 789–798

A. Levy and Y.-F. Man, Surface Degradation of Ductile Metals in Elevated Temperature Gas-Particle Streams, Wear, 1986, 111(2), p 173–186

A.V. Levy, J. Yan, and J. Patterson, Elevated Temperature Erosion of Steels, Wear, 1986, 108(1), p 43–60

J.K.N. Murthy and B. Venkataraman, Abrasive Wear Behaviour of WC-CoCr and Cr3C2-20(NiCr) Deposited by HVOF and Detonation Spray Processes, Surf. Coat. Technol., 2006, 200(8), p 2642–2652

M.M. Stack, N. Corlett, and S. Zhou, Some Thoughts on the Effect of Elastic Rebounds on the Boundaries of the Aqueous Erosion-Corrosion Map, Wear, 1998, 214(2), p 175–185

P.R. Krishnamoorthy, S. Seetharamu, and P. Sampathkumaran, Influence of the Mass Flux and Impact Angle of the Abrasive on the Erosion Resistance of Materials Used in Pulverized Fuel Bends and Other Components in Thermal Power Stations, Wear, 1993, 165(2), p 151–157

R. Kingswell, D.S. Rickerby, S.J. Bull, and K.T. Scott, Erosive Wear of Thermally Sprayed Tungsten Coatings, Thin Solid Films, 1991, 198(1–2), p 139–148

M. Roy, K.K. Ray, and G. Sundararajan, Erosion-Oxidation Interaction in Ni and Ni-20Cr Alloy, Metall. Mater. Trans. A, 2001, 32(6), p 1431–1451

T.H. Kosel, Solid Particle Erosion, ASM Handbook Vol. 18, ASM International, 1992, p 367

K. Anand, S.K. Hovis, H. Conrad, and R.O. Scattergood, Flux Effects in Solid Particle Erosion, Wear, 1987, 118(2), p 243–257

M. Roy, Elevated Temperature Erosive Wear of Metallic Materials, J. Phys. D Appl. Phys., 2006, 39, p R101–R124

C. Katsich, E. Badisch, M. Roy, G.R. Heath, and F. Franek, Erosive Wear of Hardfaced Fe-Cr-C Alloys at Elevated Temperature, Wear, 2009, 267(11), p 1856–1864

Acknowledgments

The work was funded by Department of Science and Technology (DST), Govt. of India, New Delhi, India, through a major research project entitled “Technological Innovations to Improve Degradation Resistance of Pulverized Coal Burner Nozzle (PCBN)”. The authors are highly grateful to DST for providing financial assistance to carry out this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, P., Sidhu, B.S. Characterization and High-Temperature Erosion Behaviour of HVOF Thermal Spray Cermet Coatings. J. of Materi Eng and Perform 25, 250–258 (2016). https://doi.org/10.1007/s11665-015-1818-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1818-1