Abstract

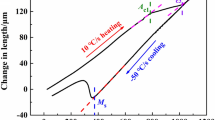

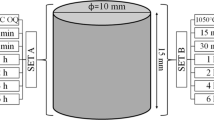

The microstructure and hardness of high-carbon martensitic stainless steel (HMSS) were investigated using thermal expansion analyzer, Thermo-calc, scanning electron microscope, x-ray diffraction, and Ultra-high temperature confocal microscope. The results indicate that the experimental steel should be austenitized in the temperature range of 1025-1075 °C, which can give a maximum hardness of 62 HRc with the microstructure consisting of martensite, retained austenite, and some undissolved carbides. With increasing austenitizing temperature, the amount of retained austenite increases, while the volume fraction of carbides increases first and then decreases. The starting temperature and finish temperature of martensite formation decrease with increasing cooling rates. Air-quenched samples can obtain less retained austenite, more compact microstructure, and higher hardness, compared with that of oil-quenched samples. For HMSS, the martensitic transformation takes place at some isolated areas with a slow nucleation rate.

Similar content being viewed by others

References

L.D. Barlow and M. Du Toit, Effect of Austenitizing Heat Treatment on the Microstructure and Hardness of Martensitic Stainless Steel AISI, 420, J. Mater. Eng. Perform., 2012, 21, p 1327–1336

A.T. Behnam, A. Fakhreddin, and H. Ali Morad, Influence of Retained Austenite on the Mechanical Properties of Low Carbon Martensitic Stainless Steel Castings, ISIJ Int., 2011, 51(3), p 471–475

A. Rajasekhar, G.M. Reddy, T. Mohandas, and V.S.R. Murti, Influence of Austenitizing Temperature on Microstructure and Mechanical Properties of AISI, 431 Martensitic Stainless Steel Electron Beam Welds, Mater. Des., 2009, 30, p 1612–1624

S.C. Krishna, N.K. Gangwar, A.K. Jha, B. Pant, and K.M. George, Effect of Heat Treatment on the Microstructure and Hardness of 17Cr-0.17N-0.43C-1.7Mo Martensitic Stainless Steel, J. Mater. Eng. Perform., 2015, 24, p 1656–1662

M. Kianezhad and S.A. Sajjadi, Improvement of Quench Factor Analysis in Phase and Hardness Prediction of a Quenched Steel, Metall. Mater. Trans. A, 2013, 44, p 2053–2059

S.K. Ghosh and S. Mondal, Effect of Heat Treatment on Microstructure and Mechanical Properties of Duplex Stainless Steel, Trans. Indian Inst. Met., 2008, 61(1), p 33–37

J.Y. Li, P. Zhao, J. Yanagimoto, S. Sugiyama, and Y.L. Chen, Effects of Heat Treatment on the Microstructures and Mechanical Properties of a New Type of Nitrogen-Containing Die Steel, Int. J. Miner. Metall. Mater., 2012, 19(6), p 511–517

Z.L. Song, X.D. Du, Y.Q. Chen, J.Q. Wang, C. Ye, and L.Y. Li, Trans. Mater. Heat. Treat., 2011, 32(5), p 95–99

W.X. Song, Metallography, 2nd ed., Metallurgical Industry Press, Beijing, 2010, p 353

S.Y. Lu, K.F. Yao, Y.B. Chen, M.H. Wang, Y. Shao, and X.Y. Ge, Effects of Austenitizing Temperature on the Microstructure and Electrochemical Behavior of a Martensitic Stainless Steel, J. Appl. Electrochem., 2015, 45, p 375–383

J.Y. Park and Y.S. Park, The Effects of Heat-Treatment Parameters on Corrosion Resistance and Phase Transformations of 14Cr-3Mo Martensitic Stainless Steel, Mater. Sci. Eng. A, 2007, 449, p 1131–1134

H.G. Fu, Y.H. Qu, J.D. Xing, X.H. Zhi, Z.Q. Jiang, M.W. Li, and Y. Zhang, Investigations on Heat Treatment of a High-Speed Steel Roll, J. Mater. Eng. Perform., 2008, 17, p 535–542

C. Garcia De Andres, L.F. Alvarez, and V. Lopez, Effects of Carbide-Forming Elements on the Response to Thermal Treatment of the X45Cr13 Martensitic Steel, J. Mater. Sci., 1998, 33(16), p 4095–4100

M.A. Alvarado-Meza, E. Garcia-Sanchez, O. Covarrubias-Alvarado, A. Salinas-Rodriguez, M.P. Guerrero-Mata, and R. Colas, Effect of the High-Temperature Deformation on the M s Temperature in a Low C Martensitic Stainless Steel, J. Mater. Eng. Perform., 2013, 22, p 345–350

B.B. He and M.X. Huang, Revealing the Intrinsic Nanohardness of Lath Martensite in Low Carbon Steel, Metall. Mater. Trans. A, 2015, 46, p 688–694

Y.H. He, Q.H. Rao, and Y.H. Tan, Investigation on the Morphology of Martensite in Carbon Steels, J. Cent. South Univ. Technol, 1996, 3(2), p 122–134

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Grant No. 51444004), and China Postdoctoral Science Foundation (Grant No. 2014M560047).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, Qt., Li, J., Shi, Cb. et al. Effect of Quenching Process on the Microstructure and Hardness of High-Carbon Martensitic Stainless Steel. J. of Materi Eng and Perform 24, 4313–4321 (2015). https://doi.org/10.1007/s11665-015-1723-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1723-7