Abstract

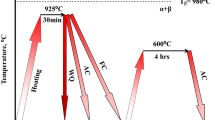

This paper investigates the effect of quenching and aging treatment on microstructure and abrasive wear of Ti-6Al-4V alloy. The as-received alloy was solution treated at 1339 K, then oil quenched, followed by aging at 823 K for 4 h (14,400 s). The microstructures of as-received and quench-aged specimens were characterized by using optical microscopy, scanning electron microscopy, energy dispersive spectroscopy, and electron backscattered diffraction techniques. The as-received specimen consisted of very fine α grains (average grain size 2 μm) with β phase uniformly dispersed throughout. The microstructure of the quench-aged specimen showed α plates (formed by the decomposition of α′ during aging). The β phase precipitated out of α′ martensite during aging and hence was dispersed uniformly in the α matrix. Ti-6Al-4V alloy was quench-aged to achieve maximum hardness with a view that the increased hardness would lead to an improvement in abrasive wear behavior. Two-body abrasive wear tests were carried out on the as-received and quench-aged specimens using pin-on-disk apparatus with SiC as abrasive media (150-grit size). The effect of sliding distance and normal load on the abrasive wear behavior was studied. The wear resistance of the as-received specimen was greater than that of quench-aged specimen, while hardness of the as-received specimen was lower than that of quench-aged specimen. The abrasive wear behavior of Ti-6Al-4V alloy has been explained based on morphology/microstructure of the alloy and the associated wear mechanism(s).

Similar content being viewed by others

References

M. Geetha, A.K. Singh, R. Asokamani, and A.K. Gogia, Ti based biomaterials—the ultimate choice for orthopaedic implants—a review, Prog. Mater Sci., 2009, 54(3), p 397–425

P.J. Blau, B.C. Jolly, J. Qu, W.H. Peter, and C.A. Blue, Tribological investigation of titanium-based materials for brakes, Wear, 2007, 263(7–12), p 1202–1211

Y.-L. Lee, Microstructure evolution of metals through thermo-mechanical processes (TMP), mechanical property of TMP samples, and small scale test samples, PhD dissertation, University of Michigan, 2010.

R. Dabrowski, The kinetics of phae transformations during continuous cooling of Ti-6Al-4V alloy from the α + β range, Arch. Metall. Mater., 2011, 56(2), p 217–221

P. Pinke, L. Caplovic, T. Kovacs, The influence of heat treatment on the microstructure of the casted Ti-6Al-4V titanium alloy, Web 11, 2011

D. Bhattacharyya, G.B. Viswanathan, S.C. Vogel, D.J. Williams, V. Venkatesh, and H.L. Fraser, A study of the mechanism of α to β phase transformation by tracking texture evolution with temperature in Ti–6Al–4V using neutron diffraction, Scr. Mater., 2006, 54(2), p 231–236

G. Lütjering, Influence of processing on microstructure and mechanical properties of (α + β) titanium alloys, Mater. Sci. Eng. A, 1998, 243(1–2), p 32–45

G. Lütjering, Property optimization through microstructural control in titanium and aluminum alloys, Mater. Sci. Eng. A, 1999, 263(2), p 117–126

G. Lutjering, J.C. Williams, Chapter 2 and 5, Titanium, 2nd edn, by B. Derby, Springer, 2007.

K.G. Budinski, Tribological properties of titanium alloys, Wear, 1991, 151(2), p 203–217

S. Yerramareddy and S. Bahadur, The effect of laser surface treatments on the tribological behavior of Ti-6Al-4V, Wear, 1992, 157(2), p 245–262

J. Qu, P.J. Blau, T.R. Watkins, O.B. Cavin, and N.S. Kulkarni, Friction and wear of titanium alloys sliding against metal, polymer, and ceramic counterfaces, Wear, 2005, 258(9), p 1348–1356

A. Molinari, G. Straffelini, B. Tesi, and T. Bacci, Dry sliding wear mechanisms of the Ti6Al4V alloy, Wear, 1997, 208(1–2), p 105–112

H. Dong, A. Bloyce, P.H. Morton, and T. Bell, Surface engineering to improve tribological performance of Ti-6Al-4V, Surf. Eng., 1997, 13(5), p 402–406

I.M. Hutchings, Tribology: Friction and Wear of Engineering Materials, Butterworth-Heinemann Ltd, Oxford, 1992

M.A. Moore, The relationship between the abrasive wear resistance, hardness and microstructure of ferritic materials, Wear, 1974, 28(1), p 59–68

J. Kalousek, D.M. Fegredo, and E.E. Laufer, The wear resistance and worn metallography of pearlite, bainite and tempered martensite rail steel microstructures of high hardness, Wear, 1985, 105(3), p 199–222

J.D. Bressan, D.P. Daros, A. Sokolowski, R.A. Mesquita, and C.A. Barbosa, Influence of hardness on the wear resistance of 17-4 PH stainless steel evaluated by the pin-on-disc testing, J. Mater. Process. Technol., 2008, 205(1–3), p 353–359

A. Baburaj, K.B.S.S. Chaudhary, R.K. Khatirkar, and S.G. Sapate, Abrasive wear behaviour of heat treated En31 steel, ISIJ Int., 2013, 53(8), p 1471–1478

E. Hornbogen, The role of fracture toughness in the wear of metals, Wear, 1975, 33(2), p 251–259

K.M. Lee and A.A. Polycarpou, Wear of conventional pearlitic and improved bainitic rail steels, Wear, 2005, 259(1–6), p 391–399

G.F.V. Voort, Mechanical grinding and polishing, ASM Handbook volume 9—Metallography and Microstructures, G.F.V. Voort, Ed., ASM International, Materials Park, OH, 2004

OIM. Analysis version 7.2, User manual: TexSEM Laboratories Inc., Draper, 2014.

M.M. Nowell and S.I. Wright, Orientation effects on indexing of electron backscatter diffraction patterns, Ultramicroscopy, 2005, 103(1), p 41–58

PDF-2, Powder Diffraction Pattern Database, ICCD, Record Number 044-1294.

O.P. Karasevskaya, O.M. Ivasishin, S.L. Semiatin, and Yu.V. Matviychuk, Deformation behavior of beta-titanium alloys, Mater. Sci. Eng. A, 2003, 354(1–2), p 121–132

B.D. Cullity, Elements of X-ray diffraction, 2nd ed., Addison-Wesley Publishing Company, Boston, 1978

R.K. Khatirkar and B.S. Murty, Structural changes in iron powder during ball milling, Mater. Chem. Phys., 2010, 123(1), p 247–253

B. Verlinden, J. Driver, I. Samajdar, and R.D. Doherty, Thermo-Mechanical Processing of Metallic Materials, Elsevier, Amsterdam, 2007

H. Mecking, Preferred Orientation in Deformed Metals and Rocks: An Introduction to Modern Texture Analysis, H.R. Wenk, Ed., Academic Press Inc, New York, 1985, p 267–306

H. Francillette, M. Benmaouche, and N. Gauquelin, Anisotropic behavior of a Ti–6Al–4V sheet during cold rolling: evidence of macroscopic shearing, J. Mater. Process. Technol., 2008, 198(1–3), p 86–92

R. Unnikrishnan, K.S.N.S. Idury, T.P. Ismail, A. Bhadauria, S.K. Shekhawat, R.K. Khatirkar, and S.G. Sapate, Effect of heat input on the microstructure, residual stresses and corrosion resistance of 304L austenitic stainless steel weldments, Mater. Charact., 2014, 93(10–23), p 10–23

R. Khatirkar, B. Vadavadagi, A. Haldar, and I. Samajdar, ND//〈111〉 recrystallization in interstitial free steel: the defining role of growth inhibition, ISIJ Int., 2012, 52(5), p 894–901

S.J. Wang, M.L. Sui, Y.T. Chen, Q.H. Lu, E. Ma, X.Y. Pei, and H.B. Hu, Microstructural fingerprints of phase transitions in shock-loaded iron, Sci. Rep., 2013, 3, p 1086

R.W.K. Honeycombe and H.K.D.H. Bhadeshia, Steels—Microstructure and Properties, Butterworth-Heinemann, Oxford, 1995

T. Ungár, Microstructural parameters from X-ray diffraction peak broadening, Scr. Mater., 2004, 51(8), p 777–781

R.K. Khatirkar, P. Yadav, and S.G. Sapate, Structural and wear characterization of heat treated En24 steel, ISIJ Int., 2012, 52(7), p 1370–1376

D. Banerjee, K. Muraleedharan, and J.L. Strudel, Substructure in titanium alloy martensite, Philos. Mag. A, 1998, 77(2), p 299–323

L.A. Bendersky, A. Roytburd, and W.J. Boettinger, Phase transformations in the (Ti, Al)3Nb section of the Ti-Al-Nb system—microstructural predictions based on a subgroup relation between phases, Acta Metall. Mater., 1994, 42(7), p 2323–2335

J.B. Borradaile, R.H. Jeal, Critical review—Mechanical properties of titanium alloys, Proceedings od Titanium’80, vol 1, pp. 141–152.

C. Charles, Modelling microstructure evolution of weld deposited Ti-6Al-4V, dissertation, Luleå University of Technology, 2008

L.M. Gammon, R.D. Briggs, J.M. Packard, K.W. Batson, R. Boyer, and C.W. Domby, Metallography and microstructures of titanium and its alloys, ASM Handbook Volume 9—Metallography and Microstructures, G.F.V. Voort, Ed., ASM International, Materials Park, OH, 2004

D. Bhattacharyya, G.B. Viswanathan, R. Denkenberger, D. Furrer, and H.L. Fraser, The role of crystallographic and geometrical relationships between α and β phases in an α/β titanium alloy, Acta Mater., 2003, 51(16), p 4679–4691

F.J. Humphreys and M. Hatherly, Recrystallization and related annealing phenomenon, Elsevier, Pergamon, 1995

N. Gey and M. Humbert, Characterization of the variant selection occurring during the α → β → α phase transformations of a cold rolled titanium sheet, Acta Mater., 2002, 50(2), p 277–287

L. Germain, N. Gey, M. Humbert, P. Vo, M. Jahazi, and P. Bocher, Texture heterogeneities induced by subtransus processing of near α titanium alloys, Acta Mater., 2008, 56(16), p 4298–4308

L. Germain, N. Gey, and M. Humbert, Reliability of reconstructed β-orientation maps in titanium alloys, Ultramicroscopy, 2007, 107(12), p 1129–1135

E. Tenckhoff: Deformation mechanisms, Texture and anisotropy in Zirconium and Zircaloy, STP 966, Philadelphia, 1988

W.G. Burgers, On the process of transition of the cubic-body-centered modification into the hexagonal-close-packed modification of zirconium, Physica, 1934, 1(7–12), p 561–586

S. Ankem and C.A. Greene, Recent developments in microstructure/property relationships of beta titanium alloys, Mater. Sci. Eng. A, 1999, 263(2), p 127–131

G.K. Williamson and W.H. Hall, X-ray line broadening from filed aluminium and wolfram, Acta Metall., 1953, 1(1), p 22–31

A.P. Mercer and I.M. Hutchings, The influence of atmospheric composition on the abrasive wear of titanium and Ti-6Al-4V, Wear, 1988, 124(2), p 165–176

J.H. Tylczak and A. Oregon, Metallography and microstructures of titanium and its alloys, ASM Handbook Volume 18—Friction, Lubrication, and Wear Technology, P.J. Blau, Ed., ASM International, Materials Park, OH, 1992

M. Belmonte, P. Miranzo, M.I. Osendi, and J.R. Gomes, Wear of aligned silicon nitride under dry sliding conditions, Wear, 2009, 266(1–2), p 6–12

H. Engqvist, S. Ederyd, N. Axén, and S. Hogmark, Grooving wear of single-crystal tungsten carbide, Wear, 1999, 230(2), p 165–174

Acknowledgment

The authors would like to thank Director, VNIT Nagpur for providing necessary facilities and constant encouragement to publish this paper. The authors would also like to acknowledge the use of National Facility of Texture & OIM (a DST-IRPHA facility) for EBSD measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hadke, S., Khatirkar, R.K., Shekhawat, S.K. et al. Microstructure Evolution and Abrasive Wear Behavior of Ti-6Al-4V Alloy. J. of Materi Eng and Perform 24, 3969–3981 (2015). https://doi.org/10.1007/s11665-015-1667-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1667-y