Abstract

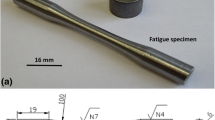

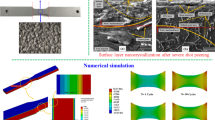

The search for the optimal Almen intensity to use in shot peening treatments to maximize the fatigue life of industrial steel components involves many different variables and physical phenomena. In this paper, the optimal peening intensity of different steel grades obtained from an AISI 4340 steel through heat treatments has been determined. Six different steel grades were subjected to shot peening treatments, which were performed under full coverage, but employing diverse Almen intensities, shot sizes and air pressures. The role of the mechanical properties of the treated steel and the applied Almen intensity on the shot peening effects were studied to understand the results obtained by means of rotating bending fatigue tests. Each steel has a specific Almen intensity value able to optimize its fatigue life, thereby allowing an optimal balance between the positive and negative effects induced by shot peening. This value, or range of values, is dependent on the mechanical properties of the treated steel, increasing with increasing steel properties up to a certain point and then decreasing for stronger steels. In these cases, over peening treatments produce sufficiently large surface defects to induce relaxation of the surface residual stress and facilitate the initiation of surface fatigue cracks.

Similar content being viewed by others

References

Metal Improvement Company, Shot Peening: Applications, 8th ed, Metal Improvement Company, USA, 2001

Shot Peening. A Dynamic Application and Its Future, Metal Finishing News, Switzerland, 2009

SAE, Manual on Shot Peening, SAE International, Warrendale, 2001

A.T. Vielma, V. Llaneza, and F.J. Belzunce, Effect of Coverage and Double Peening Treatments on the Fatigue Life of a Quenched and Tempered Structural Steel, Surf. Coat. Technol., 2014, 249, p 75–83

T. Ludian and L. Wagner, Coverage Effects in Shot Peening of Al 2024-T4, Proceedings of International Conference of Shot Peening ICSP-9, V. Schulze, 6-9 September (Paris), 2005, p 296–301

AMS, Shot Peening of Metal Parts, AMS-S-13165, SAE standard, SAE International, 1997

P.S. Prevey and J. T. Cammett, The effect of shot peening coverage on residual stress, CW and fatigue in a Ni-Cr-Mo low alloy steel, Proceedings of International Conference of Shot Peening ICSP-8, L. Wagner, 16–20 September (Munich), 2002, p 295–304

K.J. Marsh, Shot Peening: Techniques and Applications, EMAS, London, 1993

L. Wagner, Mechanical Surface Treatments on Titanium, Aluminum and Magnesium Alloys, Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process., 1999, 263, p 210–216

P. Zhang and J. Lindemann, Influence of Shot Peening on High Cycle Fatigue Properties of the High-Strength Wrought Magnesium Alloy AZ80, Scr. Mater., 2005, 52, p 485–490

W. Liu, J. Dong, P. Zhang, C. Zhai, and W. Ding, Effect of Shot Peening on Surface Characteristics and Fatigue Properties of T5-treated ZK60 Alloy, Mater. Trans., 2009, 50, p 791–798

W.C. Liu, J. Dong, P. Zhang, A.M. Korsunsky, X. Song, and W.J. Ding, Improvement of Fatigue Properties by Shot Peening for Mg-10Gd-3Y Alloys Under Different Conditions, Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process., 2011, 528, p 5935–5944

A. Zammit, M. Mhaede, M. Grech, S. Abela, and L. Wagner, Influence of Shot Peening on the Fatigue Life of Cu-Ni Austempered Ductile Iron, Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process., 2012, 545, p 78–85

S. Tekeli, Enhancement of Fatigue Strength of SAE 9245 Steel by Shot Peening, Mater. Lett., 2002, 57, p 604–608

M.L. Aggarwal, R.A. Khan, and V.P. Agrawal, Influence of Shot Peening Intensity on Fatigue Design Reliability of 65Si7 Spring Steel, Indian J. Eng. Mater. Sci., 2005, 12, p 515–520

M.A.S. Torres and H.J.C. Voorwald, An Evaluation of Shot Peening, Residual Stress and Stress Relaxation on the Fatigue Life of AISI, 4340 Steel, Int. J. Fatigue, 2002, 24, p 877–886

M.A.S. Torres, M.P. Nascimento, and H.J.C. Voorwald, Consideration of shot peening treatment applied to a high strength aeronautical steel with different hardnesses, Proceedings of International Conference of Shot Peening ICSP-8, L. Wagner, 16–20 September (Munich), 2002, p 37–43

Y.K. Gao, X.B. Li, Q.X. Yang, and M. Yao, Influence of surface integrity on fatigue strength of 40CrNi2Si2MoVA steel, Mater. Lett., 2007, 61, p 466–469

A.T. Vielma, V. Llaneza, and F.J. Belzunce, Shot Peening Intensity Optimization to Increase the Fatigue Life of a Quenched and Tempered Structural Steel, Proc. Eng., 2014, 74, p 273–278

K.A. Soady, B.G. Mellor, J. Shackleton, A. Morris, and P.A.S. Reed, The Effect of Shot Peening on Notched Low Cycle Fatigue, Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process., 2011, 528, p 8579–8588

J.C. Kim, S.K. Cheong, and H. Noguchi, Residual Stress Relaxation and Low- and High-Cycle Fatigue Behavior of Shot-Peened Medium-Carbon Steel, Int. J. Fatigue, 2013, 56, p 114–122

SAE, Test Strip, Holder and Gage for Shot Peening, J442, SAE standard, SAE International, Warrendale, 2008

SAE, Procedures for Using Standard Shot Peening Test Strip, J443, SAE standard, SAE International, Warrendale, 2003

B. Bhuvaraghan, S.M. Srinivasan, B. Maffeo, and O. Prakash, Constrained Probabilistic Multi-objective Optimization of Shot Peening Process, Eng. Optimiz., 2011, 43, p 657–673

J.K. Li, Y. Mei, W. Duo, and W. Renzhi, An Analysis of Stress Concentrations Caused by Shot Peening and Its Application in Predicting Fatigue Strength, Fatigue Fract. Eng. Mater. Struct., 1992, 15, p 1271–1279

P.S. Prevéy, X-Ray Diffraction Residual Stress Techniques, ASM Handbook, vol. 10: Materials Characterization,” ASM International, Metals Park, 1986

I.C. Noyan and J.B. Cohen, Residual Stress: Measurement by Diffraction and Interpretation, MRE, Springer-Verlag, New York, 1987

“Determination of Residual Stresses by X-ray Diffraction, Document No. 52,” National Physical Laboratory, UK, 2005

D.L. Sikarskie, On a Series Form of Correction to Stresses Measured Using X-Ray Diffraction, AIME Trans., 1967, 239, p 508–577

M.G. Moore and W.P. Evans, Mathematical Correction for Stress in Removed Layers in X-Ray Diffraction Residual Stress Analysis, SAE Trans., 1958, 66, p 340–345

D. Novovic, R.C. Dewes, D.K. Aspinwall, W. Voice, and P. Bowen, The Effect of Machined Topography and Integrity on Fatigue Life, Int. J. Mach. Tools Manuf., 2004, 44, p 125–134

M. Guagliano, Relating Almen Intensity to Residual Stresses Induced by Shot Peening: A Numerical Approach, J. Mater. Process. Technol., 2001, 110, p 277–286

Y.F. Al-Obaid, Shot Peening Mechanics: Experimental and Theoretical Analysis, Mech. Mater., 1995, 19, p 251–260

J.-C. Kim, S.-K. Cheong, and H. Noguchi, Evolution of Residual Stress Redistribution Associated with Localized Surface Microcracking in Shot-Peened Medium-Carbon Steel During Fatigue Test, Int. J. Fatigue, 2013, 55, p 147–157

Z. Qian, S. Chumbley, T. Karakulak, and E. Johnson, The Residual Stress Relaxation Behavior of Weldments During Cyclic Loading, Metall. Mater. Trans. A-Phys. Metall. Mater. Sci., 2013, 44–7, p 3147–3156

Q. Feng, C. Jiang, and Z. Xu, Residual Stress Relaxation of Shot-Peened Deformation Surface Layer on Duplex Stainless Steel Under Applied Loading, J. Mater. Eng. Perform., 2014, 23–2, p 408–412

W.Z. Zhuang and G.R. Halford, Investigation of Residual Stress Relaxation Under Cyclic Load, Int. J. Fatigue, 2001, 23, p 31–37

P. Fu and C. Jiang, Residual Stress Relaxation and Micro-Structural Development of the Surface Layer of 18CrNiMo7-6 Steel After Shot Peening During Isothermal Annealing, Mater. Des., 2014, 56, p 1034–1038

A. Wick, V. Schulze, and O. Vöhringer, Effects of Warm Peening on Fatigue Life and Relaxation Behaviour of Residual Stresses in AISI, 4140 Steel, Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process., 2000, 293, p 191–197

O. Higounenc, Correlation of Shot Peening Parameters to Surface Characteristic, Proceedings of International Conference of Shot Peening ICSP-9, V. Schulze, 6–9 September (Paris), 2005, p 28–35

Acknowledgments

Víctor Llaneza gratefully acknowledges funding from the Principado de Asturias Government, through the Severo Ochoa Programme (contract BP10-021).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Llaneza, V., Belzunce, F.J. Optimal Shot Peening Treatments to Maximize the Fatigue Life of Quenched and Tempered Steels. J. of Materi Eng and Perform 24, 2806–2815 (2015). https://doi.org/10.1007/s11665-015-1549-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1549-3