Abstract

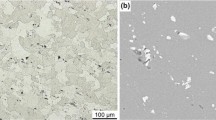

Aluminum alloy 2024-T4 specimens were exposed to atmosphere for 7, 12, and 20 years, respectively, to study long-term corrosion in a coastal environment. One-directional corrosion region and cross-directional corrosion region were defined according to corrosion characters. The statistical regularities, surface appearance, corrosion products, and cross-sectional morphology of both regions were investigated. It was found that the minimum remaining thicknesses of each region can be described by a normal distribution and linearly decrease as the exposure time is increased from 7 to 20 years. The corrosion pits, chlorine ions, and interlinked inner pits are promoting exfoliation, and the alloy’s corrosion susceptibility along the long transverse direction is strongly location dependent due to the restrictions imposed by the side material.

Similar content being viewed by others

References

S.Q. Sun, Q.F. Zheng, D.F. Li, and J.G. Wen, Long-Term Atmospheric Corrosion Behavior of Aluminium Alloy 2024 and 7075 in Urban, Coastal and Industrial Environments, Corros. Sci., 2009, 51, p 719–727

K.R. Van Horn, Aluminum, Properties, Physical Metallurgy and Phase Diagrams, Vol I, American Society for Metals, Metals Park, 1967

E.A. Baker, Long-Term Corrosion Behavior of Materials in the Marine Atmosphere, Degradation of Metals in the Atmosphere, S.W. Dean and T.S. Lee, Ed., American Society for Testing and Materials, Philadelphia, 1988, p 125–144

Z.Y. Wang, T. Ma, W. Han, and G.C. Yu, Corrosion Behavior on Aluminum Alloy LY12 in Simulated Atmospheric Corrosion Process, Trans. Nonferrous Metal. Soc., 2007, 17, p 326–334

B.B. Wang, Z.Y. Wang, W. Han, C. Wang, and W. Ke, Effects of Magnesium Chloride-Based Multicomponent Salts on Atmospheric Corrosion of Aluminum Alloy 2024, Trans. Nonferrous Metal. Soc., 2013, 23, p 1199–1208

Z. Dan, I. Muto, and N. Hara, Effects of Environmental Factors on Atmospheric Corrosion of Aluminium and its Alloy Under Constant Dew Point Conditions, Corros. Sci., 2012, 57, p 22–29

Y.Y. Shi, Z. Zhang, J.X. Su, F.H. Cao, and J.Q. Zhang, Electrochemical Noise Study on 2024-T3 Aluminum Alloy Corrosion in Simulated Acid Rain Under Cyclic Wet-Dry Condition, Electrochim. Acta, 2006, 51, p 4977–4986

M. Liu, J.P. Cai, X.Y. Zhang, F. Lu, Study on Simulative and Accelerated Tests of 2A12 Aluminum Alloy Marine Corrosion, J. Mater. Eng., 2010, z1, p 348–351, 376

J.P. Cai, M. Liu, Z.H. Luo, Z.H. Tang, B. Li, X.Y. Zhang, F. Lu, and C.H. Tao, Study on Accelerated Tests for Aluminum Alloy Atmospheric Corrosion, J. Chin. Soc. Corros. Prot., 2005, 25, p 262–266

Y.L. Cheng, Z. Zhang, F.H. Cao, J.F. Li, J.Q. Zhang, J.M. Wang, and C.N. Cao, A Study of the Corrosion of Aluminum Alloy 2024-T3 Under Thin Electrolyte Layers, Corros. Sci., 2004, 46, p 1649–1667

V. Moutarlier, M.P. Gigandet, B. Normand, and J. Pagetti, EIS Characterisation of Anodic Films Formed on 2024 Aluminium Alloy, in Sulphuric Acid Containing Molybdate or Permanganate Species, Corros. Sci., 2005, 47, p 937–951

A. Astarita, C. Bitondo, A. Squillace, E. Armentani, and F. Bellucci, Stress Corrosion Cracking Behaviour of Conventional and Innovative Aluminium Alloys for Aeronautic Applications, Surf. Interface Anal., 2013, 45, p 1610–1618

S.J. Ketcham and E.J. Jankowsky, Developing an Accelerated Test: Problems and Pitfalls, Laboratory Corrosion Tests and Standards, STP 866, G.S. Haynes and R. Babioan, Ed., American Society for Testing and Materials, West Conshohocken, 1985, p 14

F. Corvo, T. Perez, L.R. Dzib, Y. Martin, A. Castaneda, E. Gonzalez, and J. Perez, Outdoor-Indoor Corrosion of Metals in Tropical Coastal Atmospheres, Corros. Sci., 2008, 50, p 220–230

F. Corvo, A.D. Torrens, N. Betancourt, J. Perez, and E. Gonzalez, Indoor Atmospheric Corrosion in Cuba. A Report About Indoor Localized Corrosion, Corros. Sci., 2007, 49, p 418–435

A.R. Mendoza and F. Corvo, Outdoor and Indoor Atmospheric Corrosion of Non-ferrous Metals, Corros. Sci., 2000, 42, p 1123–1147

Y.J. Liu, Z.Y. Wang, and W. Ke, Study on Influence of Native Oxide and Corrosion Products on Atmospheric Corrosion of Pure Al, Corros. Sci., 2014, 80, p 169–176

J.A. Gonzalez, M. Morcillo, E. Escudero, V. Lopez, and E. Otero, Atmospheric Corrosion of Bre and Anodized Aluminum in a Wide Range of Environment Conditions. Part I: Visual Observations and Gravimetric Results, Surf. Coat. Technol., 2002, 153, p 225–234

A.S. Elola, T.F. Otero, and A. Porro, Evolution of the Pitting of Aluminum Exposed to the Atmosphere, Corrosion, 1992, 48, p 854–863

S.Q. Sun, Q.F. Zheng, D.F. Li, S.Q. Hu, and J.G. Wen, Exfoliation Corrosion of Extruded 2024-T4 in the Coastal Environments in China, Corros. Sci., 2011, 53, p 2527–2538

Q.F. Zheng, S.Q. Sun, J.G. Wen, and D.F. Li, Atmospheric Corrosion Behaviours of Aluminum and Aluminum Alloys in Desert Atmosphere of Southern Xinjiang Province, China, Chin. J. Nonferrous Met., 2009, 19, p 353–359

S.Q. Sun, Q.F. Zheng, D.F. Li, J. Chen, and J.G. Wen, Long-term atmospheric corrosion behavior of LY12 aluminum alloy, J. Chin. Soc. Corros. Prot., 2009, 29, p 442–446

B.B. Wang, Z.Y. Wang, W. Han, and W. Ke, Atmospheric Corrosion of Aluminium Alloy 2024-T3 Exposed to Salt Lake Environment in Western China, Corros. Sci., 2012, 59, p 63–70

D.D.L. Fuente, E. Otero-Huerta, and M. Morcillo, Studies of Long-Term Weathering of Aluminium in the Atmosphere, Corros. Sci., 2007, 49, p 3134–3148

C. Vargel, Corrosion of Aluminum, Dunod, Paris, 1999

S.A. Barter and L. Molent, Fatigue Cracking from a Corrosion Pit in an Aircraft Bulkhead, Eng. Fail. Anal., 2014, 39, p 155–163

M. Liao, G. Renaud, and N.C. Bellinger, Fatigue Modeling for Aircraft Structures Containing Natural Exfoliation Corrosion, Int. J. Fatigue, 2007, 29, p 677–686

G.J. Stephen, T. Pasang, and B.P. Withy, The Effect of Pitting Corrosion on Split Sleeve Cold Hole Expanded, Bare 7075-T651 Aluminum Alloy, J. Manuf. Process., 2013, 15, p 115–120

S.P. Knight, M. Salagaras, and A.R. Trueman, The Study of Intergranular Corrosion in Aircraft Aluminium Alloys Using X-ray Tomography, Corros. Sci., 2011, 53, p 727–734

M. Posada, L.E. Murr, C.S. Niou, D. Roberson, D. Little, R. Arrowood, and D. George, Exfoliation and Related Microstructures in 2024 Aluminum Body Skins on Aging Aircraft, Mater. Charact., 1997, 38, p 259–272

J. Wloka, T. Hack, and S. Virtanen, Influence of Temper and Surface Condition on the Exfoliation Behaviour of High Strength Al-Zn-Mg-Cu Alloys, Corros. Sci., 2007, 49, p 1437–1449

ISO/TC 156, Corrosion of Metals and Alloys, Determination of Bimetallic Corrosion in Outdoor Exposure Corrosion Tests, in ISO 7441, 1984.

ISO/TC 156, Corrosion of Metals and Alloys, Removal of Corrosion Products from Corrosion Test Specimens, in ISO 8407, 1991.

United States Department of Defense, Aircraft Structural Integrity Program, in MIL-STD-1530C (USAF), 2005.

United States Department of Defense. System safety. In MIL-STD-882E, 2012.

D.L. Simpson and C.L. Brooks, Tailoring the Structural Integrity Process to Meet the Challenges of Aging Aircraft, Int. J. Fatigue, 1999, 21, p S1–S14

D.G. Harlow and R.P. We, A Probability Model for the Growth of Corrosion Pits in Aluminum Alloys Induced by Constituent Particles, Eng. Fract. Mech., 1998, 59, p 305–325

X.H. Yang, W.X. Yao, and Y.L. Chen, Research on Mechanical Properties of LY12CZ Aluminum Alloy under Calendar Corrosion Environment, J. Mech. Strength, 2003, 25, p 227–228

Y.L. Hu, D. Li, and B.L. Guo, Statistical Study of Corrosion Dynamics Law and Method to Predict Calendar Life for LY12CZ Aluminum Alloy, Acta Aeronaut. Astronaut. Sin., 2000, 21, p 53–57

W.J. Xie, D. Li, Y.L. Hu, and B.L. Guo, Statistical Study of Corrosion Kinetics Law for LY12CZ and 7075T7351 Aluminum Alloy in EXCO Solution, Acta Aeronaut. Astronaut. Sin., 1999, 20, p 34–38

Y.L. Chen, G.Z. Lu, and C.M. Duan, A Probability Model for the Corrosion Damage of Aircraft Structure in Service Environment, Acta Aeronaut. Astronaut. Sin., 2002, 23, p 249–251

Y.L. Chen, X.H. Yang, and H.Q. Qin, Study on Corrosion Distribution Law of Aircraft Structure, Mater. Sci. Eng., 2002, 20, p 378–380

C.Y. Chen, Fatigue and Fracture, Huazhong University of Science and Technology Press, Wuhan, 2002

X.Z. Fang, Y.H. Wu, S.Z. Sun, Z.F. Yu, W.X. Ding, Z.F. Zhou, et al, Lower Confidence Limit of Reliability for Complete Sample from Normal Distribution, in GB/T 4885-2009, 2009.

Standardization Administration of the People’s Republic of China, Lower Confidence Limit of Reliability for Complete Sample from Normal Distribution, in GB/T 4885, 2009.

P. Marcus, J. Oudar, Eds., Corrosion Mechanism in Theory and Practice, Marcel Dekker, Inc., New York, 1995.

S.I. Pyun, S.M. Moon, S.H. Ahn, and S.S. Kim, Effects of Cl−, NO3 −, and SO4 2− Ions on Anodic Dissolution of Pure Aluminum in Alkaline Solution, Corros. Sci., 1999, 41, p 653–667

F.X. Song, X.M. Zhang, S.D. Liu, N.M. Han, and D.F. Li, Anisotropy of Localized Corrosion in 7075-T7451 Al Alloy Thick Plate, Trans. Nonferrous Metal. Soc., 2013, 23, p 2483–2490

Acknowledgments

Financial support for this study was Granted by National Natural Science Foundation of China (51475470).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, T., He, Y., Cui, R. et al. Long-Term Atmospheric Corrosion of Aluminum Alloy 2024-T4 in a Coastal Environment. J. of Materi Eng and Perform 24, 2764–2773 (2015). https://doi.org/10.1007/s11665-015-1541-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1541-y