Abstract

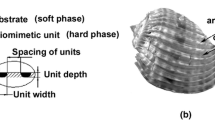

Fatigue wear resistance improvements were researched by studying experimental samples with gray cast iron fabricated with bionic units in different orientations. Experimental samples were modified by laser surface remelting, including parallel, vertical, and gradient units to the wear direction. The remelting pool was then studied to determine the micro-hardness, microstructure, alteration of phase, and etc. Lab-control fatigue wear test method was applied with the treated and untreated samples tested under the laboratorial conditions. Wear resistance result was considered as the rolling contact fatigue (RCF) resistance and mechanisms of the modified samples were experimentally investigated and discussed. Results suggested that all treated samples demonstrated the beneficial effect on the RCF improvement due to lack of graphite and reinforcement of treated region. Results also indicated the sample with fastigiated units was more effective than that with vertical units or parallel units to the wear direction. Influence of the sample unit’s angle which intensely depended on the conditions of actual application, however, was not identified.

Similar content being viewed by others

Reference

G. Bertolino and J.E. Perez-Ipiña, Geometrical Effects on Lamellar Grey Cast Iron Fracture Toughness, J. Mater. Process. Technol., 2006, 179, p 202–206

T. Willidal, W. Bauer, and P. Schumacher, Stress/Strain Behaviour and Fatigue Limit of Grey Cast Iron, Mater. Sci. Eng. A, 2005, 413-414, p 578–582

D.A. Colombo, M.D. Echeverría, S. Laino, R.C. Dommarco, and J.M. Massone, Rolling Contact Fatigue Resistance of PVD CrN and TiN Coated Austempered Ductile Iron, Wear, 2013, 308, p 35–45

K. Shi, S. Hu, and H. Zheng, Microstructure and Fatigue Properties of Plasma Transferred Arc Alloying TiC-W-Cr on Gray Cast Iron, Surf. Coat. Technol., 2011, 206, p 1211–1217

L. Chao, R. Lakshminarayanan, D.K. Shetty, and R. Cutler, Rolling Contact Fatigue and Wear of CVD SiC with Residual Surface Compression, J. Am. Ceram. Soc., 1995, 78(9), p 2307–2313

A. Makela, P. Vouristo, M. Lahdensuo, K. Niemi, and T. Mantyla, Rolling Contact Fatigue Testing of Thermally Sprayed Coatings, Proceedings of the 7th International Thermal Spray Conference, Boston, Massachuesetts, 20-24 June 1994, p 759-763

R. Nieminen, P. Vouristo, K. Niemi, T. Mantyla, and G. Barbezat, Rolling Contact Fatigue Failure Mechanisms in Plasma and HVOF Sprayed WC-Co Coatings, Wear, 1997, 212, p 66–77

S. Stewart and R. Ahmed, Rolling Contact Fatigue of Surface Coatings—A Review, Wear, 2002, 253, p 1132–1144

M.Y.P. Costa, M.L.R. Venditti, M.O.H. Cioffi, H.J.C. Voorwald, V.A. Guimarães, and R. Ruas, Fatigue Behavior of PVD Coated Ti-6Al-4V Alloy, Int. J. Fatigue., 2011, 33, p 759–765

J. Mucha, An Experimental Analysis of Effects of Various Material Tool’s Wear on Burr During Generator Sheets Blanking, Int. J. Adv. Manuf. Technol., 2010, 50, p 495–507

L.B. Niu, M. Hojamberdiev, and Y.H. Xu, Preparation of In Situ-Formed WC/Fe Composite on Gray Cast Iron Substrate by a Centrifugal Casting Process, J. Mater. Process. Technol., 2010, 210, p 1986–1990

J. Grum and R. Sturm, Influence of Laser Surface Melt-Hardening Conditions on Residual Stresses in Thin Plates, Surf. Coat. Technol., 1998, 100-101, p 455–458

M.A.S. Torres and H.J.C. Voorwald, An Evaluation of Shot Peening, Residual Stress and Stress Relaxation on the Fatigue Life of AISI, 4340 Steel, Int. J. Fatigue, 2002, 24, p 877–886

J. Grum and R. Sturm, A New Experimental Technique for Measuring Strain and Residual Stresses During a Laser Remelting Process, J. Mater. Process. Technol., 2004, 147, p 351–358

X. Tong, H. Zhou, Z. Zhang, N. Sun, H. Shan, and L. Ren, Effects of Surface Shape on Thermal Fatigue Resistance of Biomimetic Non-smooth Cast Iron, Mater. Sci. Eng. A, 2007, 467, p 97–103

Y. Iino and K. Shimoda, Effect of Overlap Pass Tempering on Hardness and Fatigue Behaviour in Laser Heat Treatment of Carbon Steel, J. Mater. Sci. Lett., 1987, 6, p 1193–1194

J. Grum and R. Sturm, Deformation of Specimen During Laser Surface Remelting, J. Mater. Eng. Perform., 2000, 9, p 138–146

H. Zhou, N. Sun, H. Shan, D. Ma, X. Tong, and L. Ren, Bio-inspired Wearable Characteristic Surface: Wear Behavior of Cast Iron with Biomimetic Units Processed by Laser, Appl. Surf. Sci., 2007, 253, p 9513–9520

C. Wang, H. Zhou, Z. Zhang, Z. Jing, D. Cong, C. Meng, and L. Ren, Tensile Property of Low Carbon Steel with Gridding Units, Appl. Surf. Sci., 2013, 273, p 128–134

D. Zeng, L. Lu, Z. Li, J. Zhang, X. Jin, and M. Zhu, Influence of Laser Dispersed Treatment on Rolling Contact Wear and Fatigue Behavior of Railway Wheel Steel, Mater. Des., 2014, 54, p 137–143

E. Hornbogen, Fracture Toughness and Fatigue Crack Growth of Grey Cast Irons, J. Mater. Sci., 1985, 20, p 3897–3905

J. Grum and R. Sturm, Microstructure Analysis of Nodular Iron 400-l2 After Laser Surface Melt Hardening, Mater. Charact., 1996, 37, p 81–88

Hertz, Uber die Berührung fester elastischer Körper, J. Reine Angew Math., 1882, 92, p 156–171

Y. Kimura, M. Sekizawa, and A. Nitanai, Wear and Fatigue in Rolling Contact, Wear, 2002, 253, p 9–16

J. Ringsberg, M. Loo-Morrey, B. Josefson, A. Kapoor, and J.H. Beynon, Prediction of Fatigue Crack Initiation for Rolling Contact Fatigue, Int. J. Fatigue, 2000, 22, p 205–215

J. Ortiz, A. Cisilino, and J. Otegui, Boundary Element Analysis of Fatigue Crack Propagation Micromechanisms in Austempered Ductile Iron, Eng. Anal. Bound. Elements, 2001, 25, p 467–473

T. David and L. Jianchun, Short Fatigue Crack Growth in Cast Iron Described Using P-a Curves, Int. J. Fatigue, 1995, 17, p 201–206

P. Ma, L. Qian, J. Meng, S. Liu, and F. Zhang, Fatigue Crack Growth Behavior of a Coarse- and a Fine-Grained High Manganese Austenitic Twin-Induced Plasticity Steel, Mater. Sci. Eng. A, 2014, 605, p 160–166

G.R. Irwin, Plastic Zone Near a Crack and Fracture Toughness, Proceedings of the Seventh Ordnance Materials Conference, vol. IV. Syracuse University, New York, p 63–78

L. Haenny and G. Zambelli, The Stiffness and Modulus of Elasticity of Grey Cast Irons, J. Mater. Sci. Lett., 1983, 2, p 239–242

Acknowledgments

This article was supported by Project 985 - High Performance Materials of Jilin University and the Project 985 - Bionic Engineering Science and Technology Innovation and National Natural Science Foundation of China (No. 51275200).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, ZK., Zhou, T., Zhang, Hf. et al. Influence of Orientations of Bionic Unit Fabricated by Laser Remelting on Fatigue Wear Resistance of Gray Cast Iron. J. of Materi Eng and Perform 24, 2511–2520 (2015). https://doi.org/10.1007/s11665-015-1499-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1499-9