Abstract

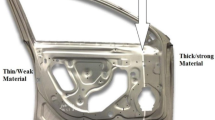

In the present work, tailor friction stir welded blanks (TFSWBs) were fabricated successfully using 2.0-mm-thick AA5754-H22 and AA5052-H32 sheet metals with optimized tool design and process parameters. Taguchi L9 orthogonal array has been used to design the friction stir welding experiments, and the Grey relational analysis has been applied for the multi objective optimization in order to maximize the weld strength and total elongation reducing the surface roughness and energy consumption. The formability of the TFSWBs and parent materials was evaluated and compared in terms of limiting drawing ratio (LDR) using a conventional circular die. It was found that the formability of the TFSWBs was comparable with that of both the parent materials without failure in the weldment. A modified conical tractrix die (MCTD) was proposed to enhance the LDR of the TFSWBs. It was found that the formability was improved by 27% using the MCTD.

Similar content being viewed by others

References

J.C. Mombo Caristan, V. Lobring, W. Prange, and A. Frings, Tailored Welded Blanks: A New Alternative in Automobile Body Design, Industrial Laser Handbook, Springer, Heidelberg, 1992, p 89–102

M. Merklein, M. Johannes, M. Lechner, and A. Kuppert, A Review on Tailored Blanks—Production, Applications and Evaluation, J. Mater. Process. Technol., 2014, 214, p 151–162

H. Shao, J. Gould, and C. Albright, Laser Blank Welding High-Strength Steels, Metall. Mater. Trans. B, 2007, 38, p 321–331

A.A. Zadpoor, J. Sinke, and R. Benedictus, Mechanics of Tailor Welded Blanks: An Overview, Key Eng. Mater., 2007, 344, p 373–382

S.K. Panda and D. Ravi, Kumar, Experimental and Numerical Studies on the Forming Behavior of Tailor Welded Steel Sheets in Biaxial Stretch Forming, Mater. Des., 2010, 31, p 1083–1365

N. Farabi, D.L. Chen, and Y. Zhou, Tensile Properties and Work Hardening Behavior of Laser-Welded Dual-Phase Steel Joints, J. Mater. Eng. Perform., 2012, 21, p 222–230

J.R. Davis, Aluminum and Aluminum Alloys, 5th ed., ASM International, Materials Park, 1993, p 784

S.S. Birley and P.E. Roper, Fusion Welding of Aluminum Alloys, 4564743, USA, 1986

W.M. Thomas, E.D. Nicholas, J.C. Needham, M.G. Murch, S.P. Temple, and C.J. Dawes, Friction Stir Butt Welding, PCT/GB92/02203, 1991

N. Pathak, K. Bandyopadhyay, M. Sarangi, and S.K. Panda, Microstructure and Mechanical Performance of Friction Stir Spot-Welded Aluminum-5754 Sheets, J. Mater. Eng. Perform., 2013, 22(1), p 131–141

R.S. Mishra and Z.Y. Ma, Friction Stir Welding and Processing, Mater. Sci. Eng. R Reports, 2005, 50(1), p 1–78

R. Nandan, T. Debroy, and H. Bhadeshia, Recent Advances in Friction-Stir Welding-Process, Weldment Structure and Properties, Prog. Mater Sci., 2008, 53(6), p 980–1023

P.L. Threadgill, A.J. Leonard, H.R. Shercliff, and P.J. Withers, Friction Stir Welding of Aluminium Alloys, Int. Mater. Rev., 2009, 54, p 49

K.V. Jata and S.L. Semiatin, Continuous Dynamic Recrystallization During Friction Stir Welding of High Strength Aluminum Alloys, Scr. Mater., 2000, 43, p 743

L. Fratini, G. Buffa, D. Palmeri, J. Hua, and R. Shivpuri, Material Flow in FSW of AA7075-T6 Butt Joints: Continuous Dynamic Recrystallization Phenomena, J. Eng. Mater. Technol., 2006, 128, p 428

A. Arora, Z. Zhang, A. De, and T. DebRoy, Strains and Strain Rates During Friction Stir Welding, Scr. Mater., 2009, 61, p 863

M.P. Miles, B.J. Decker, and T.W. Nelson, Formability and Strength of Friction Stir Welded Aluminum Sheets, Metall. Mater. Trans. A, 2004, 35A, p 3461

M.P. Miles, D.W. Melton, and T.W. Nelson, Formability of Friction-Stir-Welded Dissimilar-Aluminum-Alloy Sheets, Metall. Mater. Trans. A, 2005, 36, p 3335

Y.S. Sato, Y. Sugiura, Y. Shoji, S.H.C. Park, H. Kokawa, and K. Ikeda, Post-weld Formability of Friction Stir Welded Al Alloy 5052, Mater. Sci. Eng. A, 2004, 369, p 138

T. Hirata, T. Oguri, H. Hagino, T. Tanaka, S.W. Chung, Y. Takigawa, and K. Higashi, Influence of Friction Stir Welding Parameters on Grain Size and Formability in 5083 Aluminum Alloy, Mater. Sci. Eng. A, 2007, 456, p 344

G. Buffa, L. Fratini, J. Hua, and R. Shivpuri, Friction Stir Welding of Tailored Blanks: Investigation on Process Feasibility, CIRP Ann. Manuf. Technol., 2006, 55, p 279

M.B. Silva, M. Skjoedt, P. Vilaça, N. Bay, and P.A.F. Martins, Single Point Incremental Forming of Tailored Blanks Produced by Friction Stir Welding, J. Mater. Process. Technol., 2009, 209, p 811

C. Leitão, B. Emílio, B.M. Chaparro, and D.M. Rodrigues, Formability of Similar and Dissimilar Friction Stir Welded AA5182-H111 and AA6061-T4 Tailored Blanks, Mater. Des., 2009, 30, p 3235

S. Hazra, D. Williams, R. Roy, R. Aylmore, and A. Smith, Effect of Material and Process Variability on the Formability of Aluminium Alloys, J. Mater. Process. Technol., 2011, 211, p 1516

B.L. Juneja, Fundamentals of Metal Forming Processes, New Age International, New Delhi, 2006, p 463

R. Narayanasamy and C. Loganathan, The Influence of Friction on the Prediction of Wrinkling of Prestrained Blanks When Drawing Through a Conical Die, Mater. Des., 2007, 28, p 904

A. Arora, A. De, and T. DebRoy, Toward Optimum Friction Stir Welding Tool Shoulder Diameter, Scr. Mater., 2011, 64, p 9

Z. Hu, S. Yuan, X. Wang, G. Liu, and Y. Huang, Effect of Post-Weld Heat Treatment on the Microstructure and Plastic Deformation Behavior of Friction Stir Welded 2024, Mater. Des., 2011, 32, p 5055–5060

K.N. Krishnan, On the Formation of Onion Rings in Friction Stir Welds, Mater. Sci. Eng. A, 2002, 327, p 246

D.K. Karupannasamy, J. Hol, M.B. de Rooij, T. Meinders, and D.J. Schipper, A Friction Model for Loading and Reloading Effects in Deep Drawing Processes, Wear, 2014, 318, p 27

ASTM E8/E8M-11, Standard Test Methods for Tension Testing of Metallic Materials, Annual Book of ASTM Standards, ASTM, 2012, p 1-27

L.M.A. Hezam, M.A.Ã. Hassan, I.M. Hassab-Allah, and M.G. El-Sebaie, Development of a New Process for Producing Deep Square Cups Through Conical Dies, Int. J. Mach. Tools Manuf, 2009, 49, p 773

A. Fehrenbacher, N.A. Duffie, N.J. Ferrier, F.E. Pfefferkorn, and M.R. Zinn, Toward Automation of Friction Stir Welding Through Temperature Measurement and Closed-Loop Control, J. Manuf. Sci. Eng., 2011, 133, p 051008

H. Zhang, S.B. Lin, L. Wu, J.C. Feng, and S.L. Ma, Defects Formation Procedure and Mathematic Model for Defect Free Friction Stir Welding of Magnesium Alloy, Mater. Des., 2006, 27, p 805

D.K. Leu, The Limiting Drawing Ratio for Plastic Instability of the Cup-Drawing Process, J. Mater. Process. Technol., 1999, 86, p 168–176

R.K. Verma and S. Chandra, An Improved Model for Predicting Limiting Drawing Ratio, J. Mater. Process. Technol., 2006, 172, p 218–224

D. Julong, Introduction to Grey System Theory, J. Grey Syst., 1989, 1, p 1

K. Bandyopadhyay, S.K. Panda, and P. Saha, Investigations Into the Influence of Weld Zone on Formability of Fiber Laser-Welded Advanced High Strength Steel, J. Mater. Eng. Perform., 2014, 23(4), p 1465–1479

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kesharwani, R.K., Panda, S.K. & Pal, S.K. Experimental Investigations on Formability of Aluminum Tailor Friction Stir Welded Blanks in Deep Drawing Process. J. of Materi Eng and Perform 24, 1038–1049 (2015). https://doi.org/10.1007/s11665-014-1361-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1361-5