Abstract

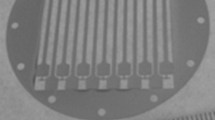

This study aims to examine the effect of annealing conditions on nitinol (NiTi) characteristics and applies this knowledge to fabricate a NiTi-copper shape memory alloy bimorph actuator. The effect of the annealing conditions was investigated at various temperatures, i.e., 500, 600, and 650 °C, for 30 min. With the characterizations using x-ray diffraction, energy dispersive spectroscopy, and differential scanning calorimetry techniques, the results showed that annealing temperatures at 600 and 650 °C were able to appropriately form the crystalline structure of NiTi. However, at these high annealing temperatures, the oxide on a surface was unavoidable. In the fabrication of actuator, the annealing at 650 °C for 30 min was chosen, and it was performed at two pre-stressing conditions, i.e., straight and curved molds. From static and dynamic response experiments, the results suggested that the annealing temperature significantly affected the deflection of the actuator. On the other hand, the effect of pre-stressing conditions was relatively small. Furthermore, the micro gripper consisting of two NiTi-copper bimorph actuators successfully demonstrated for the viability of small object manipulation as the gripper was able to grasp and hold a small plastic ball with its weight of around 0.5 mg.

Similar content being viewed by others

References

P. Krulevitch, A.P. Lee, P.B. Ramsey, J.C. Trevino, J. Hamilton, and M.A. Northrup, Thin Film Shape Memory Alloy Microactuators, J. Microelectromechanical Syst., 1996, 5(4), p 270–282

S. Miyazaki and A. Ishida, Martensitic Transformation and Shape Memory Behavior in Sputter-Deposited TiNi-Base Thin Films, Mater. Sci. Eng., 1999, A273–275, p 106–133

W. Huang, On the Selection of Shape Memory Alloys for Actuators, Mater. Des., 2002, 23, p 11–19

B. Winzek, S. Schmitz, H. Rumpf, T. Sterzl, R. Hassdorf, S. Thienhaus, J. Feydt, M. Moske, and E. Quandt, Recent Developments in Shape Memory Thin Film Technology, Mater. Sci. Eng. A, 2004, 378, p 40–46

Y. Fu, H. Du, W. Huang, S. Zhang, and M. Hu, TiNi-Based Thin Films in MEMS Applications: A Review, Sens. Actuators A, 2004, 112, p 395–408

Y. Bellouard, Shape Memory Alloys for Microsystems: A Review from a Material Research Perspective, Mater. Sci. Eng. A, 2008, 481–482, p 582–589

L. Fumagalli, F. Butera, and A. Coda, SmartFlex® NiTi Wires for Shape Memory Actuators, J. Mater. Eng. Perform., 2009, 18, p 691–695

M. Frotscher, F. Kahleyss, T. Simon, D. Biermann, and G. Eggeler, Achieving Small Structures in thin NiTi Sheets for Medical Applications with Water Jet and Micro Machining: A Comparison, J. Mater. Eng. Perform., 2011, 20, p 776–782

Y.H. Li, M.K. Li, F.L. Meng, and W.T. Zheng, Investigation on Mechanical Properties of Deformation TiNi Thin Films, J. Mater. Eng. Perform., 2012, 21, p 2691–2694

K. Lygin, S. Langbein, P. Labenda, and T. Sadek, Methodology for the Development, Production and Validation of R-Phase Actuators, J. Mater. Eng. Perform., 2012, doi:10.1007/s11665-012-0285-1

E. Makino, T. Mitsuya, and T. Shibata, Fabrication of TiNi Shape Memory Micropump, Sens. Actuators A, 2001, 88, p 256–262

F. Sassa, Y. Al-Zain, T. Ginoza, S. Miyazaki, and H. Suzuki, Miniaturized Shape Memory Alloy Pumps for Stepping Microfluidic Transport, Sens. Actuators B, 2012, 165, p 157–163

S. Takeuchi and I. Shimoyama, A Three-Dimensional Shape Memory Alloy Microelectrode with Clipping Structure for Insect Neural Recording, J. Microelectromechanical Syst., 2000, 9(1), p 24–31

J.J. Gill, D.T. Chang, L.A. Momoda, and G.P. Carman, Manufacturing Issues of Thin Film NiTi Microwrapper, Sensors Actuators A, 2001, 93, p 148–156

Y.Q. Fu, J.K. Luo, S.E. Ong, S. Zhang, A.J. Flewitt, and W.I. Milne, A Shape Memory Microcage of TiNi/DLC Films for Biological Applications, J. Micromech. Microeng., 2008, 18(3), p 035026

C.Y. Chung and P.M. Chan, NiTi Shape Memory Alloy Thin Film Micro-cantilevers Array, Thin Solid Films, 2011, 519, p 5307–5309

X. Wang, Y. Bellouard, and J.J. Vlassak, Laser Annealing of Amorphous NiTi Shape Memory Alloy Thin Films to Locally Induce Shape Memory Peroperties, Acta Mater., 2005, 53, p 4955–4961

Y. Motemani, M.J. Tan, T.J. White, and W.M. Huang, Rapid Thermal Annealing of Ti-Rich TiNi Thin Films: A New Approach to Fabricate Patterned Shape Memory Thin Films, Mater. Des., 2011, 32, p 688–695

A. Pimpin, E. Wongweerayoot, and W. Srituravanich, Two-Step Electroplating Process in Fabrication of Thermal Bimorph Cantilever Actuator for Flow Control Application, Appl. Mech. Mater., 2012, 225, p 367–371

K.T. Liu and J.G. Duh, Hardness Evolution of NiTi and NiTiAl Thin Films Under Various Annealing Temperatures, Surf. Coat. Technol., 2008, 202, p 2737–2742

S. Sanjabi and Z.H. Barber, The Effect of Film Composition on the Structure and Mechanical Properties of NiTi Shape Memory Thin Films, Surf. Coat. Technol., 2010, 204, p 1299–1304

A. Kumar, S.K. Sharma, S. Bysakh, S.V. Kamat, and S. Mohan, Effect of Substrate and Annealing Temperatures on Mechanical Properties of Ti-Rich NiTi Films, J. Mater. Sci. Technol., 2010, 26(11), p 961–966

G.S. Firstov, R.G. Vitchev, H. Kumar, B. Blanpain, and J. Van Humbeeck, Surface Oxidation of NiTi Shape Memory Alloy, Biomaterials, 2002, 23, p 4863–4871

A. Undisz, R. Hanke, and M. Rettenmayr, Effect of Heating Rate on Surface Composition of Annealed NiTi, Shape Memory and Superelastic Technologies, Prague, Czech Republic, 2013

D. Vojtěch, M. Voděrová, J. Fojt, P. Novák, and T. Kubásek, Surface Structure and Corrosion Resistance of Short-Time Heat-Treated NiTi Shape Memory Alloy, Appl. Surf. Sci., 2010, 257, p 1573–1582

P. Surbled, C. Clerc, B. Le Pioufle, M. Ataka, and H. Fujita, Effect of the Composition and Thermal Annealing on the Transformation Temperatures of Sputtered TiNi Shape Memory Alloy Thin Films, Thin Solid Films, 2001, 401, p 52–59

J. Khalil-Allafi, G. Eggeler, A. Dlouhy, W.W. Schmahl, and C. Somsen, On the Influence of Heterogeneous Precipitation on Martensitic Transformations in a Ni-Rich Shape Memory Alloy, Mater. Sci. Eng. A, 2004, 378, p 148–151

Acknowledgment

This research was financially supported by the 90th Anniversary of Chulalongkorn University Fund (Ratchadaphiseksomphot Endowment Fund) and Special Task Force for Activating Research (STAR) of Chulalongkorn University, Thailand through the Micro-Nano Fabrication Technology Research Group (GSTAR 56-005-21-002). In addition, the authors would like to thank Dr. Anurat Wisitsoraat (Microelectronics and MEMS laboratory, NECTEC) and Dr. Tachai Luangvaranunt (Department of Metallurgical Engineering, Chulalongkorn University) for their assistance in sample preparation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wongweerayoot, E., Srituravanich, W. & Pimpin, A. Fabrication and Characterization of Nitinol-Copper Shape Memory Alloy Bimorph Actuators. J. of Materi Eng and Perform 24, 635–643 (2015). https://doi.org/10.1007/s11665-014-1334-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1334-8