Abstract

The aim of this work was to characterize the structure and electrochemical behavior of a silicon-doped diamond-like carbon (DLC) film deposited by hollow cathode plasma immersion ion process (HCPIIP) on a cylinder liner for heavy duty diesel engine. The film structure was characterized by scanning electron microscopy, x-ray diffraction, and Raman spectroscopy. Nanoindentation tests were performed to evaluate the film hardness and Young’s modulus. Monitoring of the open circuit potential with time, electrochemical impedance spectroscopy (EIS), and potentiodynamic polarization measurements was performed in a solution consisting of 0.25 wt.% NaCl + 5.0 wt.% H2SO4 at room temperature. The results showed that the film has an amorphous nature consisting of a mixture of sp3 and sp2-like carbon bonds with an I D/I G ratio of 0.87. Nanoindentation tests showed that the H/E ratio of the DLC film was 0.102. EIS measurements indicated that the impedance values were higher for the DLC-coated material. Potentiodynamic polarization curves revealed that the corrosion current density was almost three times lower for the coated alloy. The HCPIIP process was considered successful to enhance the surface properties of the cylinder liner.

Similar content being viewed by others

References

K. Bobzin, N. Bagcivan, S. Theiß, R. Weiß, U. Depner, T. Troßmann, J. Ellermeier, and M. Oechsner, Behavior of DLC Coated Low-Alloy Steel Under Tribological and Corrosive Load: Effect of Top Layer and Interlayer Variation, Surf. Coat. Technol., 2013, 215, p 110–118

A. Suzuki, Y. Aiyama, M. Tokoro, H. Sekiguchi, and M. Masuko, Friction and Wear Characteristics of Hydrogenated Diamond-like Carbon Films Formed on the Roughened Stainless Steel Surface, Wear, 2010, 269, p 118–124

R. Morgenstern, W. Kiessling, S, Reichstein. Reduced Friction Losses and Wear by DLC Coating of Piston Pins, ASME Internal Combustion Engine Division, Proceedings of 2008 Fall Technical Conference, April 27-30, 2008 (Chicago, IL), ASME, 2008 (ICES2008-1650)

K. Bewilogua, G. Brauer, A. Dietz, J. Gabler, G. Goch, B. Karpuschewski, and B. Szyszka, Surface Technology for Automotive Engineering, CIRP Ann., 2009, 58, p 608–627

O. Sato, M. Takiguchi, A. Takayuki, Y. Seki, K. Fujimura, Y. Tateishi, Improvement of Piston Lubrication in a Diesel Engine by Means of Cylinder Surface Roughness, Proceedings of SAE International Congress, March 8-11, 2004 (Detroit, MI), SAE Int., 2004 (SAE 2004-01-0604)

A. Ferrarese, M. Dias, R.A. Bruno, E. Rejowski, Solutions to Heavy Duty Diesel engines after Proconve P7, 21th SAE BRASIL International Congress and Exhibition São Paulo, Brazil, October 2-4, 2012 (Detroit, MI), SAE Int., 2012 (SAE 2012-36-0358)

Rejowski, E. Caracterização e desempenho de um filme de carbono amorfo hidrogenado tipo diamante (a-C:H) dopado com silício, aplicado em camisa de cilindro de motor à combustão interna (Caracterization and performance of Hidrogen Diamond-Like Carbon Film Doped with Silicon (a-C:H) Applied in Heavy Duty Diesel Liner), Master Thesis on Nuclear Materials Technology, Nuclear and Energy Research Institute (IPEN), São Paulo, Brazil, 2012, in Portuguese

C.A. Charitidis, Nanomechanical and Nanotribological Properties of Carbon-Based Thin Films: A Review, Int. J. Refract. Met. Hard Mater., 2010, 28(1), p 51–70

A.L. Baia Neto, R.A. Santos, F.L. Freire Jr., S.S. Camargo Jr., R. Carius, and F. Finger, Relation Between Mechanical and Structural Properties of Silicon-Incorporated Hard a-C:H Films, Thin Solid Films, 1997, 293, p 206–211

A.K. Gangopadhyay, P.A. Willermet, M.A. Tamor, and W.C. Vassel, Amorphous Hydrogenated Carbon Films for Tribological Applications I. Development of Moisture Insensitive Films Having Reduced Compressive Stress, Tribol. Int., 1997, 30(1), p 19–28

E. Rejowski, P. Mordente, M.F. Pillis, T. Casserly, Application of DLC Coating in Cylinder Liners for Friction Reduction, SAE Tech. Pap. Ser., 2012-01-1329, 2012

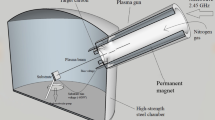

D. Lusk, T. Casserly, M. Gupta, K. Boinapally, Y. Cao, R. Ramamurti, and P. Desai, A High Density Hollow Cathode Plasma PECVD Technique for Deposition Films on the Internal Surfaces of Cylindrical Substrates, Plasma Process Polym., 2009, 6, p S429–S432

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, 7(6), p 1564–1580

EVV Der Automobilindustrie, 230-214, Resistance of Metallic Materials to Condensate Corrosion in Exhaust Gas-Carrying Components-Testing Methods, June 2010

S.-S. Hadinata, M.-T. Lee, S.-J. Pan, W.-T. Tsai, C.-Y. Tai, and C.-F. Shih, Electrochemical Performances of Diamond-Like Carbon Coatings on Carbon Steel, Stainless Steel and Brass, Thin Solid Films, 2013, 529, p 412–416

A.O. Lobo, A.A. Martin, E.F. Antunes, V.J. Trava-Airoldi, and E.J. Corat, Caracterização de materiais carbonosos por espectroscopia Raman (Characterization of Carbonaceous Materials by Raman Spectroscopy), Rev. Bras. Appl. Vacuo., 2005, 24(2), p 98–103 (in portuguese)

J. Robertson, Properties of Diamond-Like Carbon, Surf. Coat. Technol., 1992, 50(3), p 185–203

K.C. Walter, H. Kung, T. Levine, J.T. Tesmer, P. Kodali, B.P. Wood, D.J. Rej, M. Nastasi, J. Koskinen, and J.-P. Hirvonen, Characterization and Performance of Diamond-Like Carbon Films Synthesized by Plasma and Ion-Beam-Based Techniques, Surf. Coat. Technol., 1995, 74-75, p 734–738

H. Liu, Q. Xu, C. Wang, X. Zhang, and B. Tang, Investigating the Microstructure and Mechanical Behaviors of DLC Films on AISI52100 Bearing Steel Surface Fabricated by Plasma Immersion Ion Implantation and Deposition, Surf. Coat. Technol., 2013, 228, p S159–S163

P.V. Bharathy, Q. Yang, M.S.R.N. Kiran, J. Rha, D. Nataraj, and D. Mangalaraj, Reactive Biased Target Ion Beam Deposited W-DLC Nanocomposite Thin Films—Microstructure and Its Mechanical Properties, Diamond Relat. Mater., 2012, 23, p 34–43

S. Yamamoto, A. Kawana, H. Ichimura, and C. Masuda, Relationship Between Tribological Properties and sp3/sp2 Structure of Nitrogenated Diamond-Like Carbon Deposited by Plasma CVD, Surf. Coat. Technol., 2012, 210, p 1–9

A. Varma, V. Palshin, and E.I. Meletis, Structure-Property Relationship of Si-DLC Films, Surf. Coat. Technol., 2001, 148, p 305–314

P. Papakonstantinou, J.F. Zhao, P. Lemoine, E.T. McAdams, and J.A. McLaughlin, The Effects of Si Incorporation on the Electrochemical and Nanomechanical Properties of DLC Thin Films, Diamond Relat. Mater., 2002, 11, p 1074–1080

J. Choi, S. Nakao, S. Miyagawa, M. Ikeyama, and Y. Miyagawa, The Effects of Si Incorporation on the Thermal and Tribological Properties of DLC Films Deposited by PBII&D with Bipolar Pulses, Surf. Coat. Technol., 2007, 201, p 8357–8361

W.-J. Wu, T.-M. Pai, and M.-H. Hon, Wear Behavior of Silicon-Containing Diamond-Like Carbon Coatings, Diamond Relat. Mater., 1998, 7, p 1478–1484

A. Amanov, T. Watabe, R. Tsuboi, and S. Sasaki, Improvement in the Tribological Characteristics of Si-DLC Coating by Laser Surface Texturing Under Oil-Lubricated Point Contacts at Various Temperatures, Surf. Coat. Technol., 2013, 232, p 549–560

A. Bendavid, P.J. Martin, C. Comte, E.W. Preston, A.J. Haq, F.S.M. Ismail, and R.K. Singh, The Mechanical and Biocompatibility Properties of DLC-Si Films Prepared by Pulsed DC Plasma Activated Chemical Vapor Deposition, Diamond Relat. Mater., 2007, 16, p 1616–1622

M. Ikeyama, S. Nakao, Y. Miyagawa, and S. Miyagawa, Effects of Si Content in DLC Films on Their Friction and Wear Properties, Surf. Coat. Technol., 2005, 191, p 38–42

A. Leyland and A. Matthews, On the Significance of the H/E Ratio in Wear Control: A Nanocomposite Coating Approach to Optimized Tribological Behavior, Wear, 2000, 246, p 1–11

S. Choudhury, M.T. Laugier, and I.Z. Rahman, Characterization of DLC Coatings Deposited by rf Magnetron Sputtering, J. Mater. Proc. Technol., 2004, 153-154, p 804–810

Y.-R. Jeng, P.-C. Tsai, K.-T. Wu, Y.-M. Wang, F.C.-N. Hong, S.-M. Huang, and K.-C. Chen, Effect of Feed Gas Composition Effects on the Nanotribological Properties of Diamond-Like Carbon Films, Thin Solid Films, 2013, 529, p 301–305

Y. Mabuchi, T. Higuchi, and V. Weihnacht, Effect of sp2/sp3 Bonding Ratio and Nitrogen Content on Friction Properties of Hydrogen-Free DLC Coatings, Tribol. Int., 2013, 62, p 130–140

U.M. Angst, B. Elsener, C.K. Larsen, and O. Vennesland, Chloride Induced Reinforcement Corrosion: Electrochemical Monitoring of Initiation Stage and Chloride Threshold Values, Corros. Sci., 2011, 53, p 1451–1464

B. Jegdic, D.M. Drazic, and J.P. Popic, Open Circuit Potentials of Metallic Chromium and Austenitic 304 Stainless Steel in Aqueous Sulphuric Acid Solution and the Influence of Chloride Ions on Them, Corros. Sci., 2008, 50, p 1235–1244

M.B. González and S.B. Saidman, Corrosion Protection Properties of Polypyrrole Electropolymerized onto Steel in the Presence of Salicylate, Prog. Org. Coat., 2012, 75, p 178–183

M. Serdar, L.V. Zulj, and D. Bjegovic, Long-Term Corrosion Behaviour of Stainless Reinforcing Steel in Mortar Exposed to Chloride Environment, Corros. Sci., 2013, 69, p 149–157

L. Wang, J.F. Su, and X. Nie, Corrosion and Tribological Properties and Impact Fatigue Behaviors of TiN- and DLC-Coated Stainless Steels in a simulated Body Fluid Environment, Surf. Coat. Technol., 2010, 205, p 1599–1605

J.H. Sui, W. Cai, L.H. Liu, and L.C. Zhao, Surface Characteristics and Electrochemical Corrosion Behavior of NiTi Coated with Diamond-Like Carbon, Mater. Sci. Eng. A, 2006, 438-440, p 639–642

R.A. Antunes, N.B. de Lima, M.A. Rizzutto, O.Z. Higa, M. Saiki, and I. Costa, Surface Interactions of a W-DLC-Coated Biomedical AISI, 316L Stainless Steel in Physiological Solution, J. Mater. Sci. Mater. Med., 2013, 24, p 863–876

G. Venktasubramanian, M.A. Sheik, and K.J. Aboy, Effect of pH on the Corrosion Behavior of Aluminium Alloy Welded Plate in Chloride Solutions, Res. J. Chem. Sci., 2013, 3, p 74–80

G.A. Zhang and Y.F. Cheng, On the Fundamentals of Electrochemical Corrosion of X65 Steel in CO2-Containing Formation Water in the Presence of Acetic Acid in Petroleum Production, Corros. Sci., 2009, 51, p 87–94

A.B. da Silva, J.A.C.P. Gomes, E. D’Elia, M.J.C. Rezende, A.C. Pinto, B.N.M. Silva, and B.V. Silva, Isatin-Derived Compounds as Carbono Steel Corrosion Inhibitors in Highly Saline Media, Int. J. Electrochem. Sci., 2013, 8, p 9317–9331

R. Sharma, P.K. Barhai, and N. Kumari, Corrosion Resistant Behavior of DLC Films, Thin Solid Films, 2008, 516, p 5397–5403

M. Azzi, P. Amirault, M. Paquette, J.E. Klemberg-Sapieha, and L. Martinu, Corrosion Performance and Mechanical Stability of 316L/DLC Coating System: Role of Interlayers, Surf. Coat. Technol., 2010, 204, p 3986–3994

R. Hang, S. Ma, and P.K. Chu, Corrosion Behavior of DLC-Coated NiTi Alloy in the Presence of Serum Proteins, Diamond Relat. Mater., 2010, 19, p 1230–1234

H.-G. Kim, S.-H. Ahn, J.-G. Kim, S.J. Park, and K.-R. Lee, Electrochemical Behavior of Diamond-Like Carbon Films for Biomedical Applications, Thin Solid Films, 2005, 475, p 291–297

I. Masami, N. Setsuo, S. Tsutomu, and C. Junho, Improvement of Corrosion Property of Mg-Alloy by DLC and Si-DLC Coatings with PBII, Technique and Multi-Target DC-RF Magnetron Sputtering, Nucl. Instrum. Methods Phys. Res. Sect. B, 2009, 267, p 1675–1679

Acknowledgments

The authors are thankful to Sub One Technology for the deposition of the DLC films, and to Prof. Evaldo José Corat from INPE for the Raman analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rejowski, E.D., de Oliveira, M.C.L., Antunes, R.A. et al. Structural Characterization and Corrosion Stability of a Si-Doped DLC Coating Applied on Cylinder Liner. J. of Materi Eng and Perform 23, 3926–3933 (2014). https://doi.org/10.1007/s11665-014-1208-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1208-0