Abstract

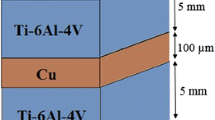

The joining of a Ti-6Al-4V alloy to a Mg-AZ31 alloy was performed using Ni electroplated coatings during the TLP bonding process. In this work, different coating thicknesses were used ranging from 1 to 20 μm. The effect of the coat thickness on microstructural developments and mechanical properties was studied. The bonded specimens were examined by metallographic examination, scanning electron microscopy, and X-ray diffraction analysis. It was observed that as the coat thickness increased from 1 to 12 μm, the joint shear strength increased from 9 to 47 MPa. A further increase in coat thickness had a detrimental effect on the bond strength, and a lower value of 11 MPa was recorded. The mechanism of joint formation includes three stages: solid-state diffusion, eutectic formation, and isothermal solidification.

Similar content being viewed by others

References

R.W. Schutz and H.B. Watkins, Recent Developments in Titanium Alloy Application in the Energy Industry, Mater. Sci. Eng. A, 1998, 243, p 305

I. Gurrapa, Characterization of Titanium Alloy Ti-6Al-4V for Chemical, Marine and Industrial Applications, Mater. Charact., 2003, 51, p 131

M.K. Kulekci, Magnesium and its Alloys Applications in Automotive Industry, Int. J. Adv. Manuf. Technol., 2007, 39, p 851

B.L. Mordike and T. Ebert, Magnesium Properties, Applications, Potential, Mater. Sci. Eng. A, 2001, 302, p 37

A.M. Atieh and T.I. Khan, Effect of Process Parameters on Semi-solid TLP Bonding of Ti-6Al-4V to Mg-AZ31, J. Mater. Sci., 2013, 48, p 6737

A.M. Atieh and T.I. Khan, Transient Liquid Phase (TLP) Brazing of Mg-AZ31 and Ti-6Al-4V Using Ni and Cu Sandwich Foils, Sci. Technol. Weld. Join., 2014, 19, p 333

W. Elthalabawy and T.I. Khan, Liquid Phase Bonding of 316L Stainless Steel to AZ31 Magnesium Alloy, J. Mater. Sci. Technol., 2011, 27, p 22

W. MacDonald and T. Eagar, Transient Liquid Phase Bonding Processes, Proceedings of the TMS Symposium Materials Science Joining, TMS, Warrendale, PA, 1991, pp. 93–100

Y. Zhou, W.F. Gale, and T.H. North, Modelling of Transient Liquid Phase Bonding, Int. Mater. Rev., 1995, 40, p 181

K. Cooke, Diffusion Bonding and Characterization of a Dispersion Strengthened Aluminum Alloy, University of Calgary, Calgary, 2011

J. Miettinen, Thermodynamic Description of Cu-Mg-Ni and Cu-Mg-Zn Systems, CALPHAD, 2008, 32, p 389

R. Bormann and K. Zöltzer, Determination of the Thermodynamic Functions and Calculation of Phase Diagrams for Metastable Phases, Phys. Status Solid A, 1992, 131, p 691

Y. Zhong, M. Yang, and Z.K. Liu, Contribution of First-Principles Energetics to Al-Mg Thermodynamic Modeling, CALPHAD, 2005, 29, p 303

F. Zhang, S.L. Chen, Y.A. Chang, and U.R. Kattner, A Thermodynamic Description of the Ti-Al System, Intermetallics, 1997, 5, p 471

J. Miettinen, Thermodynamic Description of the Cu-Al-Ni System at the Cu-Ni Side, CALPHAD, 2005, 29, p 40

W. Elthalabawy, Diffusion Bonding Behavior and Characterization of Joints Made Between 316L Stainless Steel Alloy and AZ31 Magnesium Alloy, University of Calgary, Calgary, 2010

N.S. Bosco and F.W. Zok, Critical Interlayer Thickness for Transient Liquid Phase Bonding in the Cu-Sn System, Acta Mater., 2004, 52, p 2965

V. Raghavan, Al-Ni-Ti (Aluminum-Nickel-Titanium), J. Phase Equilib. Diffus., 2009, 31, p 55

V. Raghavan, Al-Ni-Ti (Aluminum-Nickel-Titanium), J. Phase Equilib. Diffus., 2005, 26, p 268

V. Raghavan, Al-Ni-Ti-V (Aluminum-Nickel-Titanium-Vanadium), J. Phase Equilib. Diffus., 2005, 26, p 281

E. Semenova, Aluminium-Magnesium-Nickel, New Series, Landolt-Börnstein, 1991, pp. 150–156

V. Raghavan, Al-Mg-Ni (Aluminum-Magnesium-Nickel), J. Phase Equilib. Diffus., 2009, 30, p 274

H.T. Yuan, L.B. Wang, R. Cao, Y.J. Wang, Y. Zhang, D.Y. Yan, W.H. Zhang, and W.L. Gong, Electrochemical Characteristics of Mg2−x Al x Ni (0 < x<0.5) Alloys, J. Alloy. Compd., 2000, 309, p 208

L. Guanglie, C. Linshen, W. Lianbang, and Y. Huantang, Study on the Phase Composition of Mg2−xM x Ni (M = Al, Ti) Alloys, J. Alloy. Compd., 2001, 321, L1

F. Islam and M. Medraj, The Phase Equilibria in the Mg-Ni-Ca System, CALPHAD, 2005, 29, p 289

I.Y. Zavaliy, R.V. Denys, V.V. Berezovets, and V. Paul Boncour, Phase Relationships in the Mg-Ti-Ni System at 450 °C, Abstr. 10th Int. Conf. Cryst. Chem. Intermet. Compd./ASM Alloy Phase Diagrams Cent., 2007, p 58

H. Mehrer, editor, Diffusion in Solid Metals and Alloys, Landolt-Börnstein, New Series III/26. Table: Chemical Diffusion Tables: Fe-Ni-Nb-U, Springer, New York, 1990

I. Tuah-Poku, M. Dollar, and T. Massalski, A Study of the Transient Liquid Phase Bonding Process Applied to a Ag/Cu/Ag Sandwich Joint, Metall. Trans. A, 1988, 19, p 675

H.E. Friedrich and B.L. Mordike, Magnesium Technology Metallurgy, Design Data, and Applications, Springer, Berlin, 2006

S. Pfirrmann, C. Limberg, C. Herwig, R. Stösser, and B. Ziemer, A Dinuclear Nickel(I) Dinitrogen Complex and its Reduction in Single-Electron Steps, Angew. Chem. Int. Ed. Engl., 2009, 48, p 3357

Acknowledgments

The authors would like to acknowledge The German Jordanian University (GJU), and NSERC Canada for the financial support for this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Atieh, A.M., Khan, T.I. Effect of Interlayer Thickness on Joint Formation Between Ti-6Al-4V and Mg-AZ31 Alloys. J. of Materi Eng and Perform 23, 4042–4054 (2014). https://doi.org/10.1007/s11665-014-1179-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1179-1