Abstract

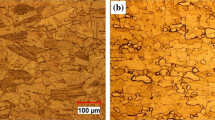

The stricter environmental, health, and safety regulations address the harmful effects of lead and provide the driving force for the development of lead-free brass alloys. Conventional leaded brass rods are widely used in several manufacturing sectors (i.e., fabrication of hydraulic components, fittings, valves, etc.) due to their superior workability in extrusion and drawing as well as their superior machinability. As machinability performance involves shear and dynamic fracture processes evolved under high strain-rate conditions, the understanding of the mechanical behavior/microstructure interaction is critical in order to successfully tailor candidate lead-free alloys for improved machinability without compromising the reliability of manufactured components. In this work, the mechanical behavior under static and dynamic loading of three lead-free brass alloys (CW510L-CW511L-C27450) in comparison to a conventional leaded brass alloy (CW614N) was studied. The fractographic evaluation of the texture of conjugate fracture surfaces was performed to identify the involved fracture mechanisms and their relation to the alloy microstructure. It was shown that the CW510L lead-free brass alloy is a potential candidate in replacing conventional CW614N leaded brass, combining high tensile strength and fracture toughness, due to the prevalence of the β-intermetallic phase in the alloy microstructure.

Similar content being viewed by others

References

G. Pantazopoulos, Leaded Brass Rods C38500 for Automatic Machining Operations: A Technical Report, Journal of Materials Engineering and Performance, 2002, 11(4), p 402–407

A.I. Toulfatzis, G.J. Besseris, G.A. Pantazopoulos, and C. Stergiou, Characterization and Comparative Machinability Investigation of Extruded and Drawn Copper Alloys Using Non-parametric Multi-response Optimization and Orthogonal Arrays, International Journal of Advanced Manufacturing Technology, 2011, 57(5–8), p 811–826

P. Garcia, S. Rivera, M. Palacios, and J. Belzunce, Comparative Study of the Parameters Influencing the Machinability of Leaded Brasses, Engineering Failure Analysis, 2010, 17(4), p 771–776

G. Pantazopoulos and A. Vazdirvanidis, Characterization of the Microstructural Aspects of Machinable α-β Brass, Microscopy and Analysis, 2008, 22(5), p 13–16

G.A. Pantazopoulos and A.I. Toulfatzis, Fracture Modes and Mechanical Characteristics of Machinable Brass Rods, Metallogr. Microstruct. Anal., 2012, 1(2), p 106–114

T. Pardoen and F. Delannay, A Method for the Metallographical Measurement of the CTOD at Cracking Initiation and the Role of Reverse Plasticity on Unloading, Engineering Fracture Mechanics, 2000, 65(4), p 455–466

T. Pardoen, M. Scibetta, R. Chaouadi, and F. Delannay, Analysis of the Geometry Dependence of Fracture Toughness at Cracking Initiation by Comparison of Circumferentially Cracked Round Bars and SENB Tests on Copper, International Journal of Fracture, 2000, 103(3), p 205–225

T. Pardoen and F. Delannay, Critical Assessment of the Application of the J-Integral and CTOD Concepts to Circumferentially Cracked Copper Bars, International Journal of Fracture, 1996, 79(4), p 373–391

P.S. Theocaris and V.N. Kytopoulos, Investigation by Scanning Electron Microscope of the Effect of Geometry and Loading Mode on Blunting of Copper Sheets, Journal Materials Science, 1992, 27(13), p 3624–3636

G. Pantazopoulos, A Review of Defects and Failures of Brass Rods and Related Components, Pract. Fail. Anal., 2003, 3(4), p 14–22

G. Pantazopoulos and A. Vazdirvanidis, Failure Analysis of Fractured Leaded-Brass (CuZn39Pb3) Extruded Hexagonal Rod, Journal of Failure Analysis and Prevention, 2008, 8(3), p 218–222

K. Laue and H. Stenger, Extrusion-Processes-Machinery-Tooling, 4th Printing, American Society for Metals, Metals Park, OH, 1981

G.E. Dieter, Mechanical Metallurgy, SI, Metric ed., McGraw-Hill, New York, NY, 1988

ASM International, Fractography, ASM Handbook, Vol 12, ASM International, Materials Park, OH, 1992

D. Hull, Fractography, observing, measuring and interpreting fracture surface topography, Cambridge University Press, Cambridge, 1999

S.P. Lynch and S. Moutsos, A Brief History of Fractography, Journal of Failure Analysis and Prevention, 2006, 6(6), p 54–69

S.P. Lynch, Failures of Structures and Components by Metal-Induced Embrittlement, Journal of Failure Analysis and Prevention, 2008, 8(3), p 259–274

G.A. Pantazopoulos, Damage Assessment Using Fractography as Failure Surface Evaluation: Applications in Industrial Metalworking Machinery, Journal of Failure Analysis and Prevention, 2011, 11(6), p 588–594

W.F. Hosford and R.M. Caddell, Metal Forming: Mechanics and Metallurgy, Prentice Hall, Englewood Cliffs, NJ, 1983

D.J. Woley and A.G. Fox, The Embrittlement of Leaded and Unleaded α + β (60-40) Brasses in the Temperature Range 300 to 500 °C, Journal of Material Science Letters, 1998, 7, p 763–765

Acknowledgments

The authors wish to express special thanks to Mr. A. Gontzes (CEO), Mr. V. Gontzes (General Manager) and Mr. I. Papachristou (Quality Department Supervisor) of FITCO S.A for providing the samples for this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Toulfatzis, A.I., Pantazopoulos, G.A. & Paipetis, A.S. Fracture Behavior and Characterization of Lead-Free Brass Alloys for Machining Applications. J. of Materi Eng and Perform 23, 3193–3206 (2014). https://doi.org/10.1007/s11665-014-1096-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1096-3