Abstract

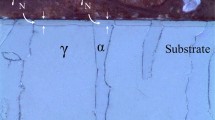

Nitrocarburizing of the type SAE 2205 duplex stainless steel was conducted at 450 °C, using a type of salt bath chemical surface treatment, and the microstructure and properties of the nitrided surface were systematically researched. Experimental results revealed that a modified layer transformed on the surface of samples with the thickness ranging from 3 to 28 μm changed with the treatment time. After 2205 duplex stainless steel was subjected to salt bath nitriding at 450 °C for time less than 8 h, the preexisting ferrite zone in the surface transformed into austenite by active nitrogen diffusion. The main phase of the nitrided layer was the expanded austenite. When the treatment time was extended to 16 h, the preexisting ferrite zone in the expanded austenite was decomposed and transformed partially into ε-nitride precipitate. When the treatment time extended to 40 h, the preexisting ferrite zone in the expanded austenite was transformed into ε-nitride and CrN precipitate. Further, a large amount of nitride precipitated from preexisting austenite zone. The nitrided layer depth thickness changed intensively with the increasing nitriding time. The growth of the nitride layer takes place mainly by nitrogen diffusion according to the expected parabolic rate law. The salt bath nitriding can effectively improve the surface hardness. The maximum values measured from the treated surface are observed to be approximately 1400 HV0.1 after 8 h, which is about 3.5 times as hard as the untreated material (396 HV0.1). Low-temperature nitriding can improve the erosion/corrosion resistance. After nitriding for 4 h, the sample has the best corrosion resistance.

Similar content being viewed by others

References

C. Blawert, A. Weisheit, B.L. Mordike, and F.M. Knoop, Plasma Immersion Ion Implantation of Stainless Steel: Austenitic Stainless Steel in Comparison to Austenitic-Ferritic Stainless Steel, Surf. Coat. Technol., 1996, 85, p 15–27

L.H. Chiu, Y.Y. Su, F.S. Chen, and H. Chang, Microstructure and Properties of Active Screen Plasma Nitrided Duplex Stainless Steel, Mater. Manuf. Process., 2010, 25, p 316–323

T.L. Christiansen and M.A.J. Somers, Controlled Dissolution of Colossal Quantities of Nitrogen in Stainless Steel, Metall. Mater. Trans. A, 2006, 37, p 675

Y. Lin, J. Lu, L. Wang, T. Xu, and Q. Xue, Surface Nanocrystallization by Surface Mechanical Attrition Treatment and its Effect on Structure and Properties of Plasma Nitrided AISI, 321 Stainless Steel, Acta Mater., 2006, 54, p 5599–5605

T.S. Hummelshøj, T.L. Christiansen, and M.A.J. Somers, Lattice expansion of carbon-stabilized expanded austenite, Scripta Mater., 2010, 63, p 761–763

L. Wang, X. Bin, Y. Zhiwei, and S. Yaqin, The Wear and Corrosion Properties of Stainless Steel Nitrided by Low-Pressure Plasma-Arc Source Ion Nitriding at Low Temperatures, Surf. Coat. Technol., 2000, 130, p 304–308

L. Wang, S. Ji, and J. Sun, Effect of Nitriding Time on the Nitrided Layer of AISI, 304 Austenitic Stainless Steel, Surf. Coat. Technol., 2006, 200, p 5067–5070

R.B. Frandsen, T. Christiansen, and M.A.J. Somers, Simultaneous Surface Engineering and Bulk Hardening of Precipitation Hardening Stainless Steel, Surf. Coat. Technol., 2006, 200, p 5160

S. Sienz, S. Mandl, and B. Rauschenbach, In Situ Stress Measurements During Low-Energy Nitriding of Stainless Steel, Surf. Coat. Technol., 2002, 156, p 185–189

A.S. Hamdy, B. Marx, and D. Butt, Corrosion Behavior of Nitride Layer Obtained on AISI, 316L Stainless Steel via Simple Direct Nitridation Route at Low Temperature, Mater. Chem. Phys., 2011, 126, p 507–514

Y. Sun and E. Haruman, Effect of Carbon Addition on Low-Temperature Plasma Nitriding Characteristics of Austenitic Stainless Steel, Vacuum, 2006, 81, p 114–119

H. Tsujimura, T. Goto, and Y. Ito, Surface Nitriding of SUS 304 Austenitic Stainless Steel by a Molten Salt Electrochemical Process, J. Electrochem. Soc., 2004, 151D, p 67–71

H. Tsujimura, T. Goto, and Y. Ito, Electrochemical formation and control of chromium nitride films in molten LiCl–KCl–Li3N systems, Electrochimica. Acta, 2002, 47, p 2725–2731

K. Funatani, Low-Temperature Salt Bath Nitriding of Steels, Met. Sci. Heat Treat., 2004, 46, p 277–281

J.W. Zhang, L.T. Lu, K. Shiozawa, W.N. Zhou, and W.H. Zhang, Effect of Nitrocarburizing and Post-Oxidation on Fatigue Behavior of 35CrMo Alloy Steel in Very High Cycle Fatigue Regime, Int. J. Fatigue, 2011, 33, p 880–886

P. Jacquet, J.B. Coudert, and P. Lourdin, How Different Steel Grades React to a Salt Bath Nitrocarburizing and Post-Oxidation Process: Influence of Alloying Elements, Surf. Coat. Technol., 2011, 205, p 4064–4067

Y.Z. Shen, K.H. Oh, and D.N. Lee, Nitriding of Steel in Potassium Nitrate Salt Bath, Scripta Mater., 2005, 53, p 1345–1349

H. Tsujimura, T. Goto, and Y. Ito, Electrochemical Surface Nitriding of Pure Iron by Molten Salt Electrochemical Process, J. Alloys Compd., 2004, 376, p 246–250

H.Y. Li, D.F. Luo, C.F. Yeung, and K.H. Lau, Microstructural Studies of QPQ Complex Salt Bath Heat-Treated Steels, J. Mater. Process. Technol., 1997, 69, p 45

C.F. Yeung, K.H. Lau, H.Y. Li, and D.F. Luo, Advanced QPC Complex Salt Bath Heat Treatment, J. Mater. Process. Technol., 1997, 66, p 249

G.-J. Li, Q. Peng, J. Wang, C. Li, Y. Wang, J. Gao, S.-Y. Chen, and B.-L. Shen, Surface Microstructure of 316L Austenitic Stainless Steel by the Salt Bath nitrocarburizing and Post-Oxidation Process Known as QPQ, Surf. Coat. Technol., 2008, 202, p 2865–2870

C.E. Foerster, F.C. Serbena, S.L.R. da Silva, C.M. Lepienski, CJdeM Siqueira, and M. Ueda, Mechanical and Tribological Properties of AISI, 304 Stainless Steel Nitrided by Glow Discharge Compared to Ion Implantation and Plasma Immersion Ion Implantation, Nucl. Instr. Meth. B, 2007, 257, p 732

L.C. Gontijo, R. Machado, E.J. Miola, L.C. Casteletti, N.G. Alcantara, and P.A.P. Nascente, Study of the S Phase Formed on Plasma-Nitrided AISI, 316L Stainless Steel, Mater. Sci. Eng. A, 2006, 431, p 315–321

J. Wang, Y. Lin, J. Yan, D. Zen, Q. Zhang, R. Huang, and H. Fan, Influence of Time on the Microstructure of AISI, 321 Austenitic Stainless Steel in Salt Bath Nitriding, Surf. Coat. Technol., 2012, 206, p 3399–3404

J. Wang, Y. Lin, J. Yan, D. Zen, R. Huang, and H. Zejing, Modification of AISI, 304 Stainless Steel Surface by the Low Temperature Complex Salt Bath Nitriding at 430°C, ISIJ Int., 2012, 52, p 1128–1133

D. Lopez, C. Sanchez, and A. Toro, Corrosion-Erosion Behavior of TiN-Coated Stainless Steels in Aqueous Slurries, Wear, 2005, 258, p 684–692

S.D. Chyou and H.C. Shih, The Effect of Nitrogen on the Corrosion of Plasma-Nitrided 4140 Steel, Corrosion, 1991, 47(1), p 31–34

C.X. Li and T. Bell, Corrosion Properties of Active Screen Plasma Nitrided 316 Austenitic Stainless Steel, Corros. Sci., 2004, 46, p 1527–1547

E. Menthe and K.-T. Rie, Further Investigation of the Structure and Properties of Austenitic Stainless Steel After Plasma Nitriding, Surf. Coat. Technol., 1999, 116–119, p 199

K.C. Chen, J.L. He, W.H. Huang, and T.T. Yeh, Study on the Solid–Liquid Erosion Resistance of Ion-Nitrided Metal, Wear, 2002, 252, p 580–585

H. Dong, S-Phase Surface Engineering of Fe–Cr, Co–Cr and Ni–Cr Alloys, Int. Mater. Rev., 2010, 55(2), p 65–98

Acknowledgments

The authors are very grateful to the National Natural Science Foundation of China (Grant No. 50901047) for financial support of the research and work involved in this study. Further acknowledgements should go to the author (J.W) along with Prof. Baoluo Shen of Sichuan University and Prof. Defu Luo of XiHua University, P.R.China, for their valuable discussions during the course of the research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yan, J., Wang, J., Lin, Y. et al. Microstructure and Properties of SAE 2205 Stainless Steel After Salt Bath Nitrocarburizing at 450 °C. J. of Materi Eng and Perform 23, 1157–1164 (2014). https://doi.org/10.1007/s11665-014-0922-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-0922-y