Abstract

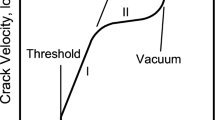

The long-term durability of high-performance ceramics-coated glass should be appropriately evaluated prior to their practical applications. Fatigue properties of such materials should be clarified to ensure the long-term durability. In this work, a borosilicate glass was coated with alumina or silicon carbide thin films by sputtering method. Fatigue tests of coated glass were conducted under three-point bending. It was clarified that the fatigue life was elongated by coating ceramic thin films on glass and the fatigue life distribution in glass coated with thicker films shifted toward longer life region. Proof testing was carried out for coated glass specimens to remove specimens having lower fatigue lives. It was suggested that proof testing for fatigue of ceramics-coated glass was effective as a screening procedure which can remove weaker specimens by static pre-loading before fatigue tests. In correlating average fatigue lives, fatigue resistance strength was introduced as the average bending strength divided by the applied maximum stress. It was revealed that the average fatigue lives of every coated glass, including average lives after proof testing, were well correlated by a power function of the fatigue resistance strength and its modified parameter, irrespective of film material and thickness and also applied stress level.

Similar content being viewed by others

References

K.H. Kim, K.C. Park, and D.Y. Ma, Structural Electrical and Optical Properties of Aluminum Doped Zinc Oxide Films Prepared by Radio Frequency Magnetron Sputtering, J. Appl. Phys., 1997, 81, p 7764–7772

Y. Fukuma, H. Asada, N. Nishimura, and T. Koyanagi, Ferromagnetic Properties of IV-VI, Diluted Magnetic Semiconductor Ge1−xMn x Te Films Prepared by Radio Frequency Sputtering, J. Appl. Phys., 2003, 93, p 4034–4039

Y. Peng, C. Park, and D.E. Laughlin, Fe3O4 Thin Films Sputter Deposited from Iron Oxide Targets, J. Appl. Phys., 2003, 93, p 7957–7959

D.A. Chang, P. Lin, and T.Y. Tseng, Optical Properties of ZrTiO4 Films Grown by Radio-Frequency Magnetron Sputtering, J. Appl. Phys., 1995, 77, p 4445–4451

G.T. Kiehne, G.K.L. Wong, and J.B. Ketterson, Optical Second-Harmonic Generation in Sputter-Deposited AlN Films, J. Appl. Phys., 1998, 84, p 5922–5927

H. Mizoguchi, N. Kitamura, K. Fukumi, T. Mihara, J. Nishii, M. Nakamura, N. Kikuchi, H. Hosono, and H. Kawazoe, Optical Properties of SrMoO3 Thin Film, J. Appl. Phys., 2000, 87, p 4617–4619

S. Venkataraj, O. Kapperiz, H. Weis, R. Drese, R. Jayavel, and M. Wuttig, Structural and Optical Properties of Thin Zirconium Oxide Films Prepared by Reactive Direct Current Magnetron Sputtering, J. Appl. Phys., 2002, 92, p 3599–3607

T. Hoshide, Strength Characteristics of Structural Ceramics, Mater. Sci. Res. Int., 1996, 2, p 220–228

T. Hoshide, M. Tanaka, and H. Tsujiai, Fatigue Properties of Borosilicate Glass Coated with Two-Layered Ceramic Thin Films, J. Mater. Eng. Perform., 2013, 22, p 1079–1084

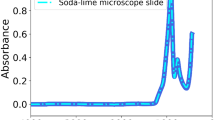

T. Hoshide, A. Nebu, and K. Hayashi, Bending Strength of Borosilicate Glass Coated with Alumina and Silicon Carbide by RF Magnetron Sputtering, JSME Int. J. A, 1998, 41, p 332–337

T. Hoshide, K. Hayashi, T. Saito, K. Katsuki, and T. Inoue, Mechanical Properties of Borosilicate Glass Coated with Alumina by Sputtering Process, Mater. Sci. Res. Int., 1996, 2, p 33–38

P.J. Burnett and D.S. Rickerby, Assessment of Coating Hardness, Surf. Eng, 1987, 3, p 69–76

“Method for Ultra-Low Loaded Hardness Test,” Japanese Industrial Standard, JIS Z 2255, 2003.

T. Hoshide, Proof Testing and Subsequent Fatigue Properties of Ceramics, Cyclic Fatigue in Ceramics, H. Kishimoto, T. Hoshide, and N. Okabe, Ed., Elsevier Sci., Amsterdam, 1995, p 207–232.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hoshide, T., Shimizu, S. & Tanaka, M. Fatigue Life Properties and Availability of Proof Testing in Ceramics-Coated Glass. J. of Materi Eng and Perform 23, 753–758 (2014). https://doi.org/10.1007/s11665-013-0844-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0844-0