Abstract

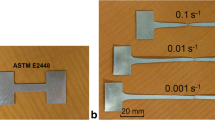

In this study, constitutive equations for superplastic materials with an extra large elongation were investigated through mechanical analysis. From the view of phenomenology, firstly, some traditional empirical constitutive relations were standardized by restricting some strain paths and parameter conditions, and the coefficients in these relations were strictly given new mechanical definitions. Subsequently, a new, general constitutive equation with varying parameters was theoretically deduced based on the general mechanical equation of state. The superplastic tension test data of Zn-5%Al alloy at 340 °C under strain rates, velocities, and loads were employed for building a new constitutive equation and examining its validity. Analysis results indicated that the constitutive equation with varying parameters could characterize superplastic flow behavior in practical superplastic forming with high prediction accuracy and without any restriction of strain path or deformation condition, showing good industrial or scientific interest. On the contrary, those empirical equations have low prediction capabilities due to constant parameters and poor applicability because of the limit of special strain path or parameter conditions based on strict phenomenology.

Similar content being viewed by others

References

M. Azpeitia, E.E. Martinez, and G. Torres, Superplastic Behavior of Zn-Al Eutectoid Alloy With 2% Cu, J. Mater. Sci., 2012, 47(17), p 6206–6212

A.J. Barnes, Superplastic Forming 40 Years and Still Growing, J. Mater. Eng. Perform., 2007, 16(4), p 440–454

P. Malek, The Deformation Structure of the Superplastic Zn-Al Alloy, Mat. Sci. Eng. A, 1999, 268(1-2), p 132–140

Y.Q. Song, The Mechanical Analysis of Superplastic Deformation in Tension, Chin. J. Mech. Eng., 2003, 139(10), p 64–72 (in Chinese)

D. Samantaray, S. Mandal, and A.K. Bhaduri, Constitutive Equations to Predict High-Temperature Flow Stress in Modified 9Cr-1Mo(P91) Steel, Mater. Des., 2010, 31, p 981–984

M. Zhou and M.P. Clode, Constitutive Equations for Modelling Flow Softening Due to Dynamic Recovery and Heat Generation During Plastic Deformation, Mech. Mater., 1998, 27, p 63–76

J.H. Hollomon, The Effect of Heat Treatment and Carbon Content on the Work Hardening Characteristics of Several Steels, Trans. ASM, 1944, 32, p 123–133

W.A. Backoken, I.R. Turner, and D.H. Avery, Superplasticity in an Al-Zn Alloy, Trans. ASM Q., 1964, 57(6), p 980–990

C. Rossard, Formation de la striction dans la déformation a chaud par traction, Rev. Met., 1966, 63(3), p 225–231

A.K. Mukherjee, J.E. Bird, and J.E. Dorn, Experimental Correlation for High-Temperature Creep, Trans. ASM, 1969, 62, p 155–179

M. Zhou and F. Dunne, Mechanisms-Based Constitutive Equations for the Superplastic Behaviour of a Titanium Alloy, J. Strain Anal. Eng., 1996, 31(3), p 187–196

E. Tanaka, S. Murakami, and H. Ishikawa, Constitutive Modeling of Superplasticity Taking Account of Grain and Cavity Growth, Trans. Jpn. Soc. Mech. Eng. A, 1997, 63(609), p 962–967

M.A. Khaleel, K.I. Johnson, C.H. Hamilton, and M.T. Smith, Deformation Modeling of Superplastic AA-5083, Int. J. Plast., 1998, 14(10-11), p 1133–1154

J. Lin, Selection of Material Models for Predicting Necking in Superplastic Forming, Int. J. Plast., 2003, 19(4), p 469–481

G. Giuliano, Constitutive Equation for Superplastic Ti-6Al-4V Alloy, Mater. Des., 2008, 29(7), p 1330–1333

N. Chandra, Constitutive Behavior of Superplastic Materials, Int. J. NonLinear Mech., 2002, 37(3), p 461–484

H.J. McQueen and N.D. Ryan, Constitutive Analysis in Hot Working, Mater. Sci. Eng. A, 2002, 322(1-2), p 43–63

Y.Q. Song, Z.P. Guan, P.K. Ma, and J.W. Song, Theoretical and Experimental Standardization of Strain Hardening Index in Tensile Deformation, Acta Metall. Sin., 2006, 42(7), p 673–680

Y.Q. Song, Z.P. Guan, Z.G. Li, and M.H. Wang, Theoretical and Metrical Standardization of Strain Rate Sensitivity Index, Sci. China E, 2007, 50(6), p 714–735

Y.Q. Song, Y.C. Cheng, and Y. Liu, Mechanical Definition and Standardized Measurement of the Strain Hardening Exponent in Tensile Deformation, Sci. China E, 2001, 44(2), p 113–122

Y.Q. Song, Y.C. Cheng, and X.W. Wang, Mechanical Meaning of Strain-Rate Sensitivity Index and Criterion of Its Measurement Under Tension Condition, Chin. J. Mech. Eng., 2000, 30(8), p 33–38 (in Chinese)

M.P. Phaniraj and A.K. Lahiri, The Applicability of Neural Network Model to Predict Flow Stress for Carbon Steels, J. Mater. Process. Technol., 2003, 141(2), p 219–227

S. Mandal, P.V. Sivaprasad et al., Artificial Neural Network Modeling to Evaluate and Predict the Deformation Behavior of Stainless Steel Type AISI, 304L During Hot Torsion, Appl. Soft. Comput., 2009, 9(1), p 237–244

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 51005098, 51005099) and the Jilin Natural Science Foundation (No. 201115015). The authors gratefully acknowledge the support from these institutions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guan, Z., Ren, M., Jia, H. et al. Constitutive Equation with Varying Parameters for Superplastic Flow Behavior. J. of Materi Eng and Perform 23, 791–798 (2014). https://doi.org/10.1007/s11665-013-0807-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0807-5