Abstract

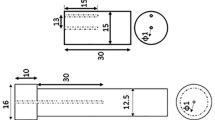

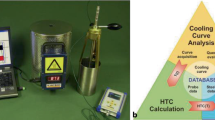

Polymer quenchants are becoming increasingly popular as substitutes for traditional quenching media in hardening metallic alloys. Water-soluble organic polymer offers a number of environmental, economic, and technical advantages, as well as eliminating the quench-oil fire hazard. The close control of polymer quenchant solutions is essential for their successful applications, in order to avoid the defects of structure of steels, such as shrinkage cracks and deformations. The aim of the present paper is to evaluate and optimize the experimental parameters of polymer quenching bath which gives the best behavior quenching process and homogeneous microstructure of the final work-piece. This study has been carried out on water-soluble polymer based on poly(N-vinyl-2-pyrrolidone) PVP K30, which does not exhibit inverse solubility phenomena in water. The studied parameters include polymer concentration, bath temperature, and agitation speed. Evaluation of cooling power and hardening performance has been measured with IVF SmartQuench apparatus, using standard ISO Inconel-600 alloy. The original numerical evaluation method has been introduced in the computation software called SQ Integra. The heat transfer coefficients were used as input data for calculation of microstructural constituents and the hardness profile of cylindrical sample.

Similar content being viewed by others

References

F. Moreaux and G. Beck, Nouvelles solutions aqueuses pour la trempe des alliages métalliques Importance de l’agitation, Traitement Thermique, 1989, 225, p 45–49

N.A. Hilder, The Behavior of Polymer Quenchants, Heat Treat. Met., 1987, 14(2), p 31–46

R.I.G. Thompson, S.J. Randles, M. Brown, and J.L. Wood, Aspects of the Use of Polyoxy-Alkylene Glycols in Polymer Quenchants, Synth. Lubr., 2006, 17(4), p 277–293

G.E. Totten, C.E. Bates, and N.A. Clinton, Handbook of Quenchants and Quenching Technology, Chapter 1, Introduction to Heat Treating of Steel, ASM International, Materials Park, OH, 1993, p 1–33

S. Segerberg, Polymer Quenchants: Evaluation of Technical and Environmental Properties, Heat Treat. Met., 1986, 13(1), p 1–3

R. Blackwood, M. Lorbach, and E.R. Mueller, Is Something Bugging Your Polymer Quenchant, Heat Treat., 1985, 17, p 40–42

N.A. Hilder, Polymer Quenchants: A Review, Heat Treat. Met., 1986, 13(1), p 15–26

R. Ikkene, Z. Koudil, and M. Mouzali, Pouvoir de refroidissement des solutions de trempe à base de polymères hydrosolubles, Conte Rendu de Chimie, 2008, 11(3), p 297–306

R. Ikkene, Z. Koudil, and M. Mouzali, Evaluation du pouvoir de durcissement d’un bain de trempe à base de polyéthylène glycol dans l’eau, Anal de Chimie, Science des Matériaux, 2009, 33(6), p 493–503

R. Ikkene, Z. Koudil, and M. Mouzali, Measurement of the Cooling Power of Polyethylene Glycol Aqueous Solutions Used as Quenching Media, J. ASTM Int., 2010, 7(2), Paper ID JAI102660

E. Troell and H. Kristofferse, Influence of Ageing and Contamination of Polymer Quenchants on Cooling Characteristics BHM, 2010, 155(3), p 114–118

M. Przylecka and W. Gestwa, The Possibility of Correlation of haRDENING power for Oils and Polymers of Quenching Mediums, Adv. Mater. Sci. Eng., 2009, Article ID 843281, p 7. doi:10.1155/2009/843281

C. Chun-huai, Z. Jing, Analysis of the Segerberg Hardening Power Equation, J. ASTM Int., 2009, 6(1), Paper ID JAI101922

J. Bodin, Cooling Characteristics of Different Quenching Media IVF, Sweden Presentation at the 2nd IMS-VHT International Meeting Yokohama, March 23-25, 2005

I. Felde and T. Reti, Evaluation of Hardening Performance of Cooling Media by Using Inverse Heat Conduction Methods and Property Prediction, J. Mech. Eng., 2010, 56(2), p 77–83

G. Ramesh and K.N. Prabhu, Cooling Characteristics of Liquid Quenchants for Heat Treatment of Castings, Indian Foundry J., 2012, 58(12), p 23–29

G.E. Totten, C.E Bates, and N.A. Clinton, Measuring Hardenability and Quench Severity, Chap. 2, Handbook of Quenchants and Quenching Technology, ASM International, Materials Park, OH, 1993

N.A. Hilder, “Aspects of the use of polyoxyalkylene glycols in polymer quenchants,” Ph.D Thesis, University of Aston, Birmingham, 1988

A.G. Ksenofontov and S.Yu. Shevchenko, Criteria for Evaluating the Cooling Capacity of Quenching Media, Met. Sci. Heat Treat., 1998, 40(10), p 408–411

R.W. Monroe and C.E. Bates, Evaluating Quenchants and Facilities for Hardening Steel, J. Heat. Treat., 1983, 3(2), p 83–99

K.N. Prabhu and P. Fernades, Nanoquenchants for Industrial Heat Treatment, J. Mater. Eng. Perform., 2008, 17(1), p 101–103

K.N. Prabhu and P. Fernandes, Heat Transfer During Quenching and Assessment of Quench Severity: A Review, J. ASTM Int., 2009, 6(1), Paper ID JAI101784

M.A. Grossmann, M. Asimov, and F. Urban, Hardenability and Its Relationship to Quenching and Some Quantitative Data in Hardenability of Alloy Steels, ASM, Materials Park, OH, 1939, p 237–249

N.N. Khavskii and R.K. Zhelokhovtseva, On the Problem of Optimum Cooling in Quenching of Steels, Izvestiya vuzov, Chem. Metall., 1982, 3, p 111–113

J. Bodin and S. Segerberg, Measurement and Evaluation of the Power of Quenching Media for Hardening, Heat Treat. Met., 1993, 20(1), p 15–23

G.E. Totten, M.E. Dakins et al., Cooling Curve Analysis of Synthetic Quenchant: A Historical Perspective, J. Heat Treat., 1988, 6(2), p 87–95

N.I. Kobasko and G.E. Totten, Design of the Industrial Quenching Processes, Trans. Mater. Heat Treat., 2004, 25(5), p 527–530

R.C. Ivanus, Measurement and Evaluation of the Quench Severity During Quenching in Various Quench Media, Metall. Int., 2010, 15(4), p 54–61

M.E. Dakins, G.E. Totten, and R.W. Heins, Cooling Curve Shape Analysis Can Help Evaluate Quenchants, Heat Treat., 1988, 12, p 38–39

N.I. Kobashko, E.C. de Souza, L.C.F. Canale, and G.E. Totten, Vegetable Oil Quenchants: Calculation and Comparison of the Cooling Properties of Series of Vegetable Oils, J. Mech. Eng., 2010, 56(2), p 131–142

ASTM D6482-06, “Standard Test Method for Determination of Cooling Characteristics of Aqueous Polymer Quenchants by Cooling Curve Analysis with Agitation (Tensi Method),” ASTM International, 100 Barr Harbor Drive, West Conshohocken, PA, USA, 19428-2959

IVF Smart Quench Manuel, Swerea IVF AB, Mölndal, Sweden, 2009

ASTM D6200-01, “Standard Test Method for Determination of Cooling Characteristics of Quench Oils by Cooling Curve Analysis,” ASTM International, 100 Barr Harbor Drive, West Conshohocken, PA, USA, 19428-2959, 2007

T. Réti and I. Felde, A Non-Linear Extension of the Additivity Rule, Comput. Mater. Sci., 1999, 15(4), p 466–482

R.W. Foreman and A. Meszaros, Polymer Quenching Update, Ind. Heat., 1984, 51(1), p 22–29

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Koudil, Z., Ikkene, R. & Mouzali, M. Cooling Capacity Optimization: Calculation of Hardening Power of Aqueous Solution Based on Poly(N-Vinyl-2-Pyrrolidone). J. of Materi Eng and Perform 23, 551–559 (2014). https://doi.org/10.1007/s11665-013-0775-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0775-9