Abstract

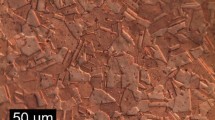

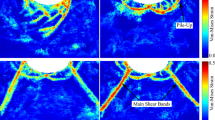

In this paper, two Indium-alloyed Cu-based bulk metallic glasses, Cu54Zr37Ti8In1 and Cu50Zr37Ti8In5, have been evaluated with nanoindentation testing. Both bulk metallic glasses have homogenous nature in structure. Both hardness and Young’s modulus of bulk metallic glasses do not show a loading rate-dependent. Addition of In decreases hardness and Young’s modulus, but increases creep-resistance of bulk metallic glasses. Indentation creep of two bulk metallic glasses has also been investigated. The displacement-time curves of creep processes were described with generalized Kelvin model. The creep displacement, compliance spectrum, and retardation spectrum for each bulk metallic glass were discussed comparatively. The results showed that Cu50Zr37Ti8In5 has better creep-resistance at room temperature and a more relaxed state.

Similar content being viewed by others

References

D.H. Bae, H.K. Lim, S.H. Kim, D.H. Kim, and W.T. Kim, Mechanical Behavior of a Bulk Cu-Ti-Zr-Ni-Si-Sn Metallic Glass Forming Nano-Crystal Aggregate Bands During Deformation in the Supercooled Liquid Region, Acta Mater., 2002, 50(7), p 1749–1759

C.L. Qin, W. Zhang, K. Asami, H. Kimura, X.M. Wang, and A. Inoue, A Novel Cu-Based BMG Composite with High Corrosion Resistance and Excellent Mechanical Properties, Acta Mater., 2006, 54(14), p 3713–3719

N. Chen, D.V. Louzguine-Luzgin, G.Q. Xie, T. Wada, and A. Inoue, Influence of Minor Si Addition on the Glass-Forming Ability and Mechanical Properties of Pd40Ni40P20 Alloy, Acta Mater., 2009, 57(9), p 2775–2780

N. Nishiyama and A. Inoue, Glass-Forming Ability of Pd42.5Cu30Ni7.5P20 Alloy with a Low Critical Cooling Rate of 0.067 K/s, Appl. Phys. Lett., 2002, 80(4), p 568–570

H. Choi-Yim, R. Busch, U. Koster, and W.L. Johnson, Synthesis and Characterization of Particulate Reinforced Zr57Nb5Al10Cu15.4Ni12.6 Bulk Metallic Glass Composites, Acta Mater., 1999, 47(8), p 2455–2462

A. Castellero, B. Moser, D.I. Uhlenhaut, F.H. Dalla Torre, and J.F. Loffler, Room-Temperature Creep and Structural Relaxation of Mg-Cu-Y Metallic Glasses, Acta Mater., 2008, 56(15), p 3777–3785

Z.P. Lu, T.T. Goh, Y. Li, and S.C. Ng, Glass Formation in La-Based La-Al-Ni-Cu-(Co) Alloys by Bridgman Solidification and Their Glass Forming Ability, Acta Mater., 1999, 47(7), p 2215–2224

Z. Bian, H. Kato, C.L. Qin, W. Zhang, and A. Inoue, Cu-Hf-Ti-Ag-Ta Bulk Metallic Glass Composites and Their Properties, Acta Mater., 2005, 53(7), p 2037–2048

A. Castellero, T.A. Baser, J. Das, P. Matteis, J. Eckert, L. Battezzati and M. Baricco, Role of crystalline precipitates on the mechanical properties of (Cu0.50Zr0.50)100-xAlx (x = 4, 5, 7) bulk metallic glasses, J. Alloy. Compd., 2011, 509, p S99-S104

D.V. Louzguine-Luzgin, G. Xie, Q. Zhang, C. Suryanarayana, and A. Inoue, Formation, Structure, and Crystallization Behavior of Cu-Based Bulk Glass-Forming Alloys, Metall. Mater. Trans. A, 2010, 41(7), p 1664–1669

J. Eckert, J. Das, K.B. Kim, F. Baier, M.B. Tang, W.H. Wang, and Z.F. Zhang, High Strength Ductile Cu-Base Metallic Glass, Intermetallics, 2006, 14(8-9), p 876–881

K. Georgarakis, A.R. Yavari, D.V. Louzguine-Luzgin, J. Antonowicz, M. Stoica, Y. Li, M. Satta, A. LeMoulec, G. Vaughan, and A. Inoue, Atomic Structure of Zr-Cu Glassy Alloys and Detection of Deviations from Ideal Solution Behavior with Al Addition by X-Ray Diffraction Using Synchrotron Light in Transmission, Appl. Phys. Lett., 2009, 94(19), p 1919121–1919123

M.M. Trexler and N.N. Thadhani, Mechanical Properties of Bulk Metallic Glasses, Prog. Mater. Sci., 2010, 55(8), p 759–839

A. Inoue, W. Zhang, T. Zhang, and K. Kurosaka, High-Strength Cu-Based Bulk Glassy Alloys in Cu-Zr-Ti and Cu-Hf-Ti Ternary Systems, Acta Mater., 2001, 49(14), p 2645–2652

C.A. Schuh and T.G. Nieh, A Nanoindentation Study of Serrated Flow in Bulk Metallic Glasses, Acta Mater., 2003, 51(1), p 87–99

T. Burgess, K.J. Laws, and M. Ferry, Effect of Loading Rate on the Serrated Flow of a Bulk Metallic Glass During Nanoindentation, Acta Mater., 2008, 56(17), p 4829–4835

B.C. Wei, L.C. Zhang, T.H. Zhang, D.M. Xing, J. Das, and J. Eckert, Strain Rate Dependence of Plastic Flow in Ce-Based Bulk Metallic Glass During Nanoindentation, J. Mater. Res., 2007, 22(2), p 258–263

K.W. Chen, S.R. Jian, P.J. Wei, J.S.C. Jang, and J.F. Lin, The study of Loading Rate Effect of A Cu-Based Bulk Metallic Glass During Nanoindentation, J. Alloy. Compd., 2010, 504, p S69–S73

J. Sort, J. Fornell, W. Li, S. Surinach, and M.D. Baro, Influence of the Loading Rate on the Indentation Response of Ti-Based Metallic Glass, J. Mater. Res., 2009, 24(3), p 918–925

W.H. Li, K. Shin, C.G. Lee, B.C. Wei, T.H. Zhang, and Y.Z. He, The Characterization of Creep and Time-Dependent Properties of Bulk Metallic Glasses Using Nanoindentation, Mater. Sci. Eng. A, 2008, 478(1-2), p 371–375

S. Lesz, R. Szewczyk, D. Szewieczek, and A. Bienkowski, The Structure and Magnetoelastic Properties of the Fe-Based Amorphous Alloy with Hf Addition, J. Mater. Process. Technol., 2004, 157, p 743–748

L. Liu, K.C. Chan, M. Sun, and Q. Chen, The Effect of the Addition of Ta on the Structure, Crystallization and Mechanical Properties of Zr-Cu-Ni-Al-Ta Bulk Metallic Glasses, Mater. Sci. Eng. A, 2007, 445, p 697–706

W. Zhou, X. Lin, and J.F. Li, Effects of Ag Addition on Crystallization, Microstructure and Mechanical Properties of Zr-Cu-Ni-Al-Ag Bulk Metallic Glasses, J. Alloy Compd., 2013, 552, p 102–106

J. Wu, Y. Pan, J. Huang, and J. Pi, Non-Isothermal Crystallization Kinetics and Glass-Forming Ability of Cu-Zr-Ti-In Bulk Metallic Glasses, Thermochim. Acta, 2013, 552, p 15–22

Y.I. Golovin, V.I. Ivolgin, V.A. Khonik, K. Kitagawa, and A.I. Tyurin, Serrated Plastic Flow During Nanoindentation of a Bulk Metallic Glass, Scr. Mater., 2001, 45(8), p 947–952

L.F. Liu, L.H. Dai, Y.L. Bai, B.C. Wei, and G.S. Yu, Strain Rate-Dependent Compressive Deformation Behavior of Nd-Based Bulk Metallic Glass, Intermetallics, 2005, 13(8), p 827–832

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Elastic-Modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, 7(6), p 1564–1583

W.C. Oliver and G.M. Pharr, Measurement of Hardness and Elastic Modulus by Instrumented Indentation: Advances in Understanding and Refinements to Methodology, J. Mater. Res., 2004, 19(1), p 3–20

R. Chen, F.Q. Yang, G.J. Fan, and P.K. Liaw, Hardness Variation Across a Zr57Ti5Cu20Ni8Al10 Bulk Metallic Glass, J. Mater. Sci., 2007, 42(6), p 2208–2211

J.L. Wu, Y. Pan and J.H. Pi, Evaluation of Cu-Zr-Ti-In Bulk Metallic Glasses via Nanoindentation, J. Mater. Eng. Perform., DOI: 10.1007/s11665-013-0519-x

W.H. Wang, Correlations Between Elastic Moduli and Properties in Bulk Metallic Glasses, J. Appl. Phys., 2006, 99(9), p 0935061–09350610

W.H. Wang, Bulk Metallic Glasses with Functional Physical Properties, Adv. Mater., 2009, 21(45), p 4524–4544

W. Martienssen and H. Warlimont, Ed., Springer Handbook of Condensed Matter and Materials Data, Springer, Berlin, 2005, p 45–158

N. Zheng, R.T. Qu, S. Pauly, M. Calin, T. Gemming, Z.F. Zhang, and J. Eckert, Design of Ductile Bulk Metallic Glasses by Adding “Soft” Atoms, Appl. Phys. Lett., 2012, 100(14), p 1419011–1419014

S. Yang, Y.W. Zhang, and K.Y. Zeng, Analysis of Nanoindentation Creep for Polymeric Materials, J. Appl. Phys., 2004, 95(7), p 3655–3666

B.C. Wei, T.H. Zhang, W.H. Li, D.M. Xing, L.C. Zhang, and Y.R. Wang, Indentation Creep Behavior in Ce-Based Bulk Metallic Glasses at Room Temperature, Mater. Trans., 2005, 46(12), p 2959–2962

K.M. Bernatz, I. Echeverria, S.L. Simon, and D.J. Plazek, Characterization of the Molecular Structure of Amorphous Selenium Using Recoverable Creep Compliance Measurements, J. Non-Cryst. Solids, 2002, 307, p 790–801

L.C. Zhang, B.C. Wei, D.M. Xing, T.H. Zhang, W.H. Li, and Y. Liu, The Characterization of Plastic Deformation in Ce-Based Bulk Metallic Glasses, Intermetallics, 2007, 15(5-6), p 791–795

Y.D. Sun, Z.Q. Li, J.S. Liu, M.Q. Cong, and J.Y. Qin, Indentation Creep Behaviors of Mg61Cu28Gd11 and (Mg61Cu28Gd11)99.5Sb0.5 Bulk Metallic Glasses at Room Temperature, J. Rare Earth, 2011, 29(3), p 253–258

Acknowledgments

Thanks for financial support from the National Natural Science Foundation of China (Grant No. 50971041). The authors also thank Computherm LLC, USA for supporting us with Pandat® software and thermodynamic database.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, J., Pan, Y. & Pi, J. Nanoindentation Mechanical Properties of Indium-Alloyed Cu-Based Bulk Metallic Glasses. J. of Materi Eng and Perform 23, 486–492 (2014). https://doi.org/10.1007/s11665-013-0765-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0765-y