Abstract

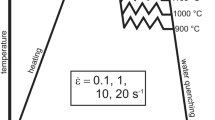

In order to study the workability of a Al-Cu-Li alloy, isothermal hot compressive deformation was investigated in the temperature range of 350-500 °C at strain rates in the range of 0.01-10/s up to a true strain of 0.9 on Gleeble-1500 mechanical testing machine. The flow stress increased rapidly to a peak value. The peak stress decreased with increasing deformation temperature and decreasing strain rate. The effects of strain rate and temperature on hot deformation behavior can be represented by a Zener-Hollomon parameter including an Arrhenius term. The influence of the strain has also been incorporated in the constitutive equation and four material constants α, n, A, and the activation energy Q were calculated by compensation of strain. The proposed constitutive equation (considering the compensation of strain) gives an accurate description for the flow stress of the Al-Cu-Li alloy.

Similar content being viewed by others

References

R.K. Gupta, N. Nayan, G. Nagasireesha, and S.C. Sharma, Development and Characterization of Al-Li Alloys, Mater. Sci. Eng. A, 2006, 420(1-2), p 228–234

R. Rioja and J. Liu, The Evolution of Al-Li Base Products for Aerospace and Space Applications, Metall. Mater. Trans. A, 2012, 43(9), p 3325–3337

J.C. Williams and E.A. Starke, Jr., Progress in Structural Materials for Aerospace Systems, Acta Mater., 2003, 51(19), p 5775–5799

X. Duan and T. Sheppard, The Influence of the Constitutive Equation on the Simulation of a Hot Rolling Process, J. Mater. Process. Technol., 2004, 150(1-2), p 100–106

J.H. Sung, J.H. Kim, and R.H. Wagoner, A Plastic Constitutive Equation Incorporating Strain, Strain-Rate, and Temperature, Int. J. Plast., 2010, 26(12), p 1746–1771

L. Wang, F. Liu, Q. Zuo, and C.F. Chen, Prediction of Flow Stress for N08028 Alloy Under Hot Working Conditions, Mater. Des., 2013, 47, p 737–745

R.N. Wright and M.S. Paulson, Constitutive Equation Development for High Strain Deformation Processing of Aluminum Alloys, J. Mater. Process. Technol., 1998, 80-81, p 556–559

Y.H. Xiao and C. Guo, Constitutive Modelling for High Temperature Behavior of 1Cr12Ni3Mo2VNbN Martensitic Steel, Mater. Sci. Eng. A, 2011, 528(15), p 5081–5087

A. Laasraoui and J. Jonas, Prediction of Steel Flow Stresses at High Temperatures and Strain Rates, Metall. Mater. Trans. A, 1991, 22(7), p 1545–1558

Y.C. Lin and G. Liu, A New Mathematical Model for Predicting Flow Stress of Typical High-Strength Alloy Steel at Elevated High Temperature, Comput. Mater. Sci., 2010, 48(1), p 54–58

J. van de Langkruis, W.H. Kool, and S. van der Zwaag, Assessment of Constitutive Equations in Modelling the Hot Deformability of Some Overaged Al-Mg-Si Alloys with Varying Solute Contents, Mater. Sci. Eng. A, 1999, 266(1-2), p 135–145

D. Samantaray, S. Mandal, and A.K. Bhaduri, A Comparative Study on Johnson Cook, Modified Zerilli-Armstrong and Arrhenius-Type Constitutive Models to Predict Elevated Temperature Flow Behaviour in Modified 9Cr-1Mo Steel, Comput. Mater. Sci., 2009, 47(2), p 568–576

C.M. Sellars and W.J.M. Tegart, Relationship Between Strength and Structure in Deformation at Elevated Temperatures, Mem. Sci. Rev. Met., 1966, 63(9), p 731–745

J.J. Jonas, C.M. Sellars, and W.J.M. Tegart, Strength and Structure Under Hot-Working Conditions, Int. Mater. Rev., 1969, 14(1), p 1–24

T. Sheppard and D. Wright, Determination of Flow Stress: Part 1 Constitutive Equation for Aluminium Alloys at Elevated Temperatures, Met. Technol., 1979, 6(1), p 215–223

T. Sheppard and A. Jackson, Constitutive Equations for Use in Prediction of Flow Stress During Extrusion of Aluminium Alloys, Mater. Sci. Technol., 1997, 13(3), p 203–209

H.J. McQueen, E. Fry, and J. Belling, Comparative Constitutive Constants for Hot Working of Al-4.4 Mg-0.7 Mn (AA5083), J. Mater. Eng. Perform., 2001, 10(2), p 164–172

H.J. McQueen and N.D. Ryan, Constitutive Analysis in Hot Working, Mater. Sci. Eng. A, 2002, 322(1), p 43–63

G. Avramovic-Cingara, H.J. McQueen, and D.D. Perovic, Comparison of Torsion and Compression Constitutive Analyses for Elevated Temperature Deformation of Al-Li-Cu-Mn Alloy, Mater. Sci. Technol., 2003, 19(1), p 11–19

C. Zener and J.H. Hollomon, Effect of Strain Rate Upon Plastic Flow of Steel, J. Appl. Phys., 1944, 15(1), p 22–32

H. Shi, A.J. McLaren, C.M. Sellars, R. Shahani, and R. Bolingbroke, Constitutive Equations for High Temperature Flow Stress of Aluminium Alloys, Mater. Sci. Technol., 1997, 13(3), p 210–216

H.J. McQueen, W.A. Wong, and J.J. Jonas, Deformation of Aluminium at High Temperatures and Strain Rates, Can. J. Phys., 1967, 45(2), p 1225–1234

N.J. Silk, S.B. Davenport, C.N. Sparks, and C.M. Sellars, Development of Constitutive Equations for Modelling of Hot Rolling, Mater. Sci. Technol., 2000, 16(5), p 539–546

O. Sherby, R. Klundt, and A. Miller, Flow Stress, Subgrain Size, and Subgrain Stability at Elevated Temperature, Metall. Trans. A, 1977, 8(6), p 843–850

R.W. Evans and G.R. Dunstan, Hot-Working and Subsequent Restoration of Commercial-Purity Aluminium, J. Inst .Met. Jan., 1971, 99, p 4–14

G. Avramovic-Cingara, D. Perovic, and H. McQueen, Hot Deformation Mechanisms of a Solution-Treated Al-Li-Cu-Mg-Zr Alloy, Metall. Mater. Trans. A, 1996, 27(11), p 3478–3490

H. McQueen, K. Conrod, and G. Avramovic-Cingara, The Hot Working Characteristics of Eutectic-Rod-Stabilized Conductor Alloys, Can. Metall. Q., 1993, 32(4), p 375–386

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ou, L., Nie, Y. & Zheng, Z. Strain Compensation of the Constitutive Equation for High Temperature Flow Stress of a Al-Cu-Li Alloy. J. of Materi Eng and Perform 23, 25–30 (2014). https://doi.org/10.1007/s11665-013-0747-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0747-0