Abstract

The aim of this study is to investigate the feasibility of using glass fibers, a recycled material from waste printed circuit boards (WPCB), as sound absorption and thermal insulation material. Glass fibers were obtained through a fluidized-bed recycling process. Acoustic properties of the recovered glass fibers (RGF) were measured and compared with some commercial sound absorbing materials, such as expanded perlite (EP), expanded vermiculite (EV), and commercial glass fiber. Results show that RGF have good sound absorption ability over the whole tested frequency range (100-6400 Hz). The average sound absorption coefficient of RGF is 0.86, which is prior to those of EP (0.81) and EV (0.73). Noise reduction coefficient analysis indicates that the absorption ability of RGF can meet the requirement of II rating for sound absorbing material according to national standard. The thermal insulation results show that RGF has a fair low thermal conductivity (0.046 W/m K), which is comparable to those of some insulation materials (i.e., EV, EP, and rock wool). Besides, an empirical dependence of thermal conductivity on material temperature was determined for RGF. All the results showed that the reuse of RGF for sound and thermal insulation material provided a promising way for recycling WPCB and obtaining high beneficial products.

Similar content being viewed by others

Introduction

As an essential part of almost all electronic and electrical equipments (EEE), printed circuit boards (PCB) are the basis of electronic industry. Technological innovation and intense marketing accelerate the update of EEE and make waste EEE one of the fastest growing segments of the global waste steam, resulting in dramatic increase of waste printed circuit boards (WPCB) (Ref 1-4). The disposal of WPCB has been attracting significant public attentions because of its potential environmental impact as well as the fertile recyclable composition. WPCB contain plenty of valuable materials, such as metallic constituents, organic resins, glass fibers, etc., which could be recycled as secondary resources (Ref 5-7). Therefore, the recycling of WPCB is an important subject concerning not only the protection of environment, but also the recovery of valuable materials.

Glass fibers take up a significant fraction (50-70 wt.%) of WPCB nonmetal material. Recovery of glass fibers was a feasible and beneficial method for WPCB recycling, and extensive studies have been devoted to this field. Quan et al. (Ref 8) reported that glass fibers could be liberated from the pyrolytic solid product of WPCB through secondary combustion. Zheng et al. (Ref 9, 10) developed a fluidized-bed technique for recovering glass fibers from WPCB nonmetal granules and the obtained fibers were successfully reused in polypropylene composite as reinforcing fillers. Liu et al. (Ref 11) presented a hydrogenative method to recycle aramid fibers from epoxy resin matrix composite. Similarly, Braun et al. (Ref 12) employed hydrogenative method to liquefy the organic resin fraction from the circuit board and reclaimed glass fibers. Although glass fibers could successfully be recovered from WPCB, recycling this material in economically and environmentally viable ways was the critical issue.

Sound absorption and thermal insulation have become more and more required in modern construction because of the increasing demand for a better environment. So far, many efforts have been devoted to the investigation on acoustic and thermal properties of recycled fibrous materials due to their good performance and low cost. Lee and Joo (Ref 13) studied the acoustic absorption coefficients for different mixtures of recycled polyester fibers with the aim of replacing the conventional materials used for sound insulation. Ersoy and Küçük (Ref 14) investigated the sound absorbing potential of waste tea-leaf-fiber and analyzed the effect of covering layers on the absorbing performance. Khedari et al. (Ref 15, 16) developed a new low-cost particleboard from durian peel and coconut coir mixture as thermal insulation product, which was effective for energy saving when used as ceiling and wall.

In this article, the objective of this research is to reuse the glass fibers recovered from WPCB as sound and thermal insulation material, with the aim to recycle this resource in a profitable way. The feasibility was evaluated in terms of sound absorption coefficient and thermal conductivity and the results were compared with some commercial insulation materials. The effect of covering layers on the acoustic performance of recovered glass fibers (RGF) was studied. Besides, the relationship between thermal conductivity and temperature was also investigated. All the results show that it is a promising way to reuse RGF as alternative sound and thermal insulation material with high added value.

Theory Background

Sound absorption ability of a material is usually described by sound absorption coefficient (α), which represents the absorption energy rate of the material against the overall incidence energy. Sound absorption coefficient is influenced by physical parameters such as porosity, flow resistivity, tortuosity, density, and thickness. In general, these parameters can synthetically be characterized by acoustic impedance (Z s), expressed by the following equation (Ref 17):

where Z r and Z i are the real and imaginary parts of acoustic impedance Z s. They represent the acoustic resistance and reactance feature of material, which indicates sound energy attenuation and energy reflection, respectively (Ref 18). If the acoustic impedance Z s of the material is a pure imaginary number (Z r = 0), the material can absorb no energy. On the other hand, if it is a pure real number, the material dissipates sound energy and the absorption coefficient is no more than 1. As shown in Eq 1, the more the resistance Z r approaches to a constant 1 and Z i verges on zero, the higher the sound absorption coefficient is.

Experimental

Preparation of Materials

WPCB were first pulverized into particles to strip and separate copper from the nonmetal materials. Then the nonmetal particles were fed into a fluidized-bed equipment to extract glass fibers. The main components of the nonmetal materials are glass fibers-reinforced thermoset resins. When nonmetals were processed in a fluidized-bed operating at high-temperature air flow, the resins contained were broken down and combusted. Then the glass fibers were recovered by a cyclone separator. More detailed information about the recycling process can be seen in previous study (Ref 9).

In order to evaluate the performance of RGF, some commercial insulation materials, such as expanded vermiculite (EV), expanded perlite (EP), and commercial glass fibers (CGF), were purchased from the market for comparison. They are all traditional insulation materials widely used in building applications (Ref 19, 20). Physical properties of all these materials were measured and calculated (Table 1). The porosity of RGF and CGF was measured using measuring cup method as was indicated by Wang and Torng (Ref 21). At first the mass and the bulk volume of certain amount of RGF were measured. And then the material was saturated with water in a measuring cup with fixed quantity of water to measure the true volume of the fibers. Sonication for 15 min has been conducted to the material to reduce the air bubbles remaining in the medium and to yield reliable results. So, the bulk density and the true density of the material were calculated and the porosity value could be approximated. The data of EV and EP were calculated by the material density provided by the manufacturers. The porosity of porous materials can be expressed by

where \( \Upomega \) is the porosity of material, \( \uprho_{\text{bulk}} \) and \( \uprho_{\text{true}} \) are the bulk density and true/solid density of material. The porosity of RGF and CGF are 92.4 and 94.5%, respectively, which are similar to those of general glass fibers.

Measurement Apparatus

The impedance tube method was used for measuring the absorption coefficient and acoustic impedance of materials. The measurement apparatus consists of two impedance tubes with diameters of 100 and 29 mm. The large tube was used for the frequency range of 100-1600 Hz and the small tube was prepared for the 500-6400 Hz measurement. A schematic diagram of the impedance tube apparatus is shown in Fig. 1. In this study, the acoustic impedance of materials was characterized by normalized specific acoustic impedance, which is a ratio of specific acoustic impedance to the characteristic impedance of air.

Experimental samples with a thickness of 50 mm were prepared for the acoustic measurement. Samples were fixed in the impedance tube with the inner surface against a rigid wall and the outer surface covered with covering layers, if necessary. In order to diminish the experimental deviation during the sampling process, the mass of each sample was rationed before measurement. Sound absorption measurement was carried out at least four times for each sample to insure the experimental accuracy.

The thermal insulation property of RGF was measured through the steady-state bi-plate technique according to ISO 8301 and ASTM C518 standards. The basic principle of operation is to create one-dimensional axial heat flux through the sample and calculate the thermal property using the Fourier equation of heat transfer:

where \( \upkappa \) is the thermal conductivity, q is the steady-state heat flow, A is the cross-sectional area of the sample, and \( - dT/dx \) is the temperature difference gradient.

A heat flow meter (NETZSCH HFM 436) was used in this study for thermal measurement. Sample with cross section of 300 × 300 mm2 and thickness of 50 mm was sandwiched between a pair of ‘hot’ plate and ‘cold’ plate. Temperature range from 10° to 50° was adapted to analyze the influence of temperature on the thermal property. Each thermal conductivity value was an average result of three measurements.

Results and Discussion

Characterization of the RGF

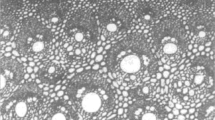

Morphological analysis of the RGF was carried out through scanning electron microscope (SEM) photomicrograph as shown in Fig. 2. It can be seen that the RGF were primarily constituted of single glass fibers with relative clean surfaces. This indicates that the thermal processing in fluidized bed can efficiently remove the resins contained in the nonmetal materials. A rough determination of the fiber size was carried out by counting fiber size through 83 microscopic images. The results show that the average diameter of these fibers is 8.74 μm and more than 90% of the fibers are longer than 0.1 mm (Fig. 3), which indicates a high aspect ratio (above 10) for the recovered fibers. This result can be responsible for the high porosity of RGF shown above (Table 1).

Acoustic Properties of RGF

Sound Absorption Ability of RGF

Sound absorption coefficients of RGF and some commercial absorbers (EV, EP, and CGF) were measured at the frequency range from 100-6400 Hz and the results were shown in Fig. 4. First, it was found that RGF exhibited a typical absorption spectrum of porous absorbing material, which rapidly increases to its first absorption peak and then gradually flattens with the increasing of incident frequency. RGF have very good low-frequency absorption ability. The average absorption coefficient of RGF (0.69) is even higher than that of CGF (0.63) in the range of 100-1000 Hz as shown in Table 2. Therefore, RGF can provide excellent noise absorption in low-frequency band which is closely associated with road traffic and other mechanical noise (Ref 22).

Besides, the sound absorption ability of RGF is distinctly better than those of EV and EP in a large frequency range. As shown in Table 2, the average absorption coefficient of RGF is obviously higher than those of EV and EP in low- and middle-frequency ranges. The reason for the absorption difference among these materials can be ascribed to their respective structure characters. Although the overall porosity of EP and EV is higher than RGF (Table 1), there are a large fraction of internal/closed pores included in these materials (Ref 23-25). However, only open pores interconnected with each other are the key factor for sound absorption (Ref 26). As for the RGF, the pores in the material are formed due to the overlapping of fibers (Ref 21, 27). So, the pores of RGF are open ones interconnected with each other which are contributable to the good absorption ability RGF. When compared with CGF, the absorption coefficient of the RGF is relatively lower in most frequency range except for the peak region of RGF. This is mainly due to the relatively high porosity of CGF, which makes it easy for sound waves to transmit inside the material.

In general, the indication of sound absorption ability by absorption coefficient would be complex since it differs in different sound frequencies. To solve this problem, a single value for evaluating the sound absorption, which called noise reduction coefficient (NRC), was calculated in this study. The NRC can be expressed by the following equation (Ref 28):

It can be seen from Table 3 that the NRC value of RGF is superior to those of EP, EV, and some other recycled absorbers from waste polyolefin plastics (Ref 29) and waste tires (Ref 30), and comparable with recycled coir fibers (Ref 31). According to the national standard (GB/T 16731-1997), materials having NCR exceeds 0.2 can be called sound absorbent material. And sound absorbers can be gradated into four levels according to NRC value:\( {\text{I}},\;{\text{NRC}} \ge 0.8;\;{\text{II}},\;0.8 > {\text{NRC}} \ge 0.6;\;{\text{III}},\;0.6 > {\text{NRC}} \ge 0.4;\;{\text{IV}},\;0.4 > {\text{NRC}} \ge 0.2.\) So, the RGF is a high efficient sound absorbing material by meeting II rating requirement.

Acoustic Impedance Analysis

In order to gain a further insight into the acoustic property of RGF, the acoustic impedances of RGF, CGF, EV, and EP were measured and compared as shown in Fig. 5. The results indicate that the sound energy reflection effect of RGF is much lower when compared with EV and EP (Fig. 5b), especially in high-frequency range, the imaginary part of RGF is rather close to the value of zero. However, the sound absorption coefficient of RGF is not very prominent between 3000 and 6400 Hz. It is found that the real part of acoustic impedance of RGF, in Fig. 5(a), is derived from the value of constant 1, which indicates its relatively low sound energy attenuation capacity. In addition, it should be noted that both the real and imaginary parts of the RGF show some deviation from the optimal values between 800 and 2600 Hz. The declined energy attenuation and strong reflection effect just explain the first absorption coefficient trough of RGF in this frequency range (Fig. 4).

The Effect of Covering Layers on the Absorption Performance of RGF

Fibrous materials covered with covering layers are typically used for fibrous absorbers to protect fibers from being scattered. In this study, a perforated panel (thickness, 3 mm; perforated ratio, 2.2%) and a nonwoven cotton layer (thickness, 3 mm) were selected as surface covering layers. The effect of covering layers on the sound absorption of the RGF was investigated.

As shown in Fig. 6, perforated panel greatly changes the effective sound absorption region of RGF. The absorption peak is shifted from 780 to 410 Hz by the plate, and consequently the absorption performance of RGF in low-frequency range was evidently improved. In the frequency range of 100 to 500 Hz, the average absorption coefficients of RGF were elevated from 0.37 to 0.64, corresponding an improvement of about 73%. However, in middle- and high-frequency ranges, the absorption of RGF is significantly depressed by the panel layer. The average absorption coefficient of the RGF is declined from 0.9 to 0.3 in the frequency range from 500 to 6400 Hz. This is mainly caused by the obstructive effect of perforated panel to the transmission of high-frequency sound waves.

On the other hand, the cotton layer just has a little effect on the performance of RGF. Because of the same fibrous structure, cotton and RGF exhibit similar sound absorption behaviors. The covering of cotton layer does not change the absorption trend of RGF, and the absorption coefficient of the RGF is just slightly improved in some frequencies due to the increase of total material thickness.

Figure 7 shows the acoustic impedance of RGF covered with perforated panel and cotton layer. The RGF covered with cotton layer exhibits similar impedance properties, both acoustic resistance and reactance, to that of single RGF material. This corresponds to the sound absorption result obtained above. For the case of perforated panel covering, the acoustic resistance is close to that of RGF covered with cotton layer. However, the absorption ability of RGF with perforated panel is much lower in middle and high frequencies. So, it can be concluded that the strong sound energy reflection caused by the covering of the panel is the main reason for the poor absorption ability of the assembly in high frequencies.

Thermal Insulation Ability of RGF

Thermal conductivity is a measure of the effectiveness of a material in conducting heat. Table 4 compares the thermal conductivity of RGF with those of some commercial and recycled insulation materials at room temperature (25 °C). It is evident that the thermal conductivity of RGF is at the same range with those of EP and EV (Ref 32) with similar densities, and obviously lower than those of some recycled materials, such as consolidated rubber crumb from waste tires and PU chip foam (Ref 26). The conductivity value of RGF is close to that of low-density rock wool, but it is a little higher than commercial glass wool (Ref 26). This could be attributed to the relatively compact structure of RGF. Nevertheless, note that materials with the thermal conductivity less than 0.12 W/m K are generally considered as thermal insulations (GB 4272-92). Therefore, it can be concluded that the RGF is a fairly good thermal insulation material.

High porosity has been proved in the RGF due to the overlapping of fibers. Pores filled by air serve as scattering centers for phonons. Heat flow transfers through solid fibers and internal pores, while the thermal conductivity of air within the pores is much lower than that of solid substance. So, the high porous structure of RGF leads to a low thermal conductivity of the material.

Application temperature may have significant influence on the thermal conductivity of materials. In this study, thermal conductivity of RGF was measured in the temperature range of 10-50 °C, which covers the majority of thermal conditions for internal application. It can be found that the thermal conductivity showed a strong linear correlation with temperature as shown in Fig. 8. Obviously, the higher of material temperature, the higher is the thermal conductivity of RGF. With the increasing of temperature from 10 to 50 °C, the thermal conductivity increased from 0.0444 to 0.0493 W/m K.

Conclusions

This study demonstrates that glass fibers recycled from WPCB have good sound and thermal insulation properties. The sound absorption coefficient of RGF is superior to those of some traditional absorbers, such as EP, EV, and some recycled absorbing materials. The sound absorption ability of RGF can reach the II rating requirement of sound absorption material according to national standard.

Covering layers have significant effect on the acoustic properties of the RGF. Perforated panel improves the low-frequency ability of the material while significantly depresses the performance in middle- and high-frequency ranges. Cotton layer has a relative small affect on the absorption ability of RGF and generally maintains the good performance of RGF.

The thermal conductivity of RGF is fairly low (0.046 W/m K at 25 °C) and it is at the same range with that of EP, EV, and rock wool. The thermal conductivity of RGF increases with the increasing temperature and exhibits a strong linear dependence on temperature.

The excellent insulation properties indicate that RGF can be used as a good alternative for commercial insulating materials. So, this study provides a bright prospect for utilization of glass fibers recycled from WPCB by giving high added values. Furthermore, this research also can serve as a practical guidance for the reuse of recycled glass fibers from other composite materials, such as sheet molding compound, bulk molding compound, etc.

References

A. Terazono, S. Murakami, N. Abe, B. Inanc, Y. Moriguchi, S. Sakai, M. Kojima, A. Yoshida, J. Li, and J. Yang, Current Status and Research on E-Waste Issues in Asia, J. Mater. Cycl. Waste Manag., 2006, 8, p 1–12

R. Widmer, H. Oswald-Krapf, D. Sinha-Khetriwal, M. Schnellmann, and H. Boni, Global Perspectives on E-Waste, Environ. Impact Assess. Rev., 2005, 25, p 436–458

H. Duan, J. Li, Y. Liu, N. Yamazaki, and W. Jiang, Characterization and Inventory of PCDD/Fs and PBDD/Fs Emissions from the Incineration of Waste Printed Circuit Board, Environ. Sci. Technol., 2011, 45, p 6322–6328

H. Yang, J. Liu, and J. Yang, Leaching Copper from Shredded Particles of Waste Printed Circuit Boards, J. Hazard. Mater., 2011, 187, p 393–400

J. Guo, J. Guo, and Z. Xu, Recycling of Non-metallic Fractions from Waste Printed Circuit Boards: A Review, J. Hazard. Mater., 2009, 168, p 567–590

J. Li, H. Lu, J. Guo, Z. Xu, and Y. Zhou, Recycle Technology for Recovering Resources and Products from Waste Printed Circuit Boards, Environ. Sci. Technol., 2007, 41, p 1995–2000

W.J. Hall and P.T. Williams, Separation and Recovery of Materials from Scrap Printed Circuit Boards, Resour. Conserv. Recycl., 2007, 51, p 691–709

C. Quan, A. Li, and N. Gao, Characterization of Products Recycling from PCB Waste Pyrolysis, J. Anal. Appl. Pyrol., 2010, 89, p 102–106

Y. Zheng, Z. Shen, S. Ma, C. Cai, X. Zhao, and Y. Xing, A Novel Approach to Recycling of Glass Fibers from Nonmetal Materials of Waste Printed Circuit Boards, J. Hazard. Mater., 2009, 170, p 978–982

Y. Zheng, Z. Shen, S. Ma, C. Cai, X. Zhao, Y. Xing, B. Guo, X. Zeng, and L. Wang, Influence of the Recycled Glass Fibers from Nonmetals of Waste Printed Circuit Boards on Properties and Reinforcing Mechanism of Polypropylene Composites, J. Appl. Polym. Sci., 2010, 118, p 2914–2920

Y. Liu, L. Li, and L. Meng, The Experimental Research on Recycling of Aramid Fibers by Solvent Method, J. Reinf. Plast. Compos., 2009, 28, p 2211–2220

D. Braun, W. Von Gentzkow, and A.P. Rudolf, Hydrogenolytic Degradation of Thermosets, Polym. Degrad. Stab., 2001, 74, p 25–32

Y. Lee and C. Joo, Sound Absorption Properties of Recycled Polyester Fibrous Assembly Absorbers, AUTEX Res. J., 2003, 3, p 78–84

S. Ersoy and H. Küçük, Investigation of Industrial Tea-Leaf-Fibre Waste Material for Its Sound Absorption Properties, Appl. Acoust., 2009, 70, p 215–220

J. Khedari, N. Nankongnab, J. Hirunlabh, and S. Teekasap, New Low-Cost Insulation Particleboards from Mixture of Durian Peel and Coconut Coir, Build. Environ., 2004, 39, p 59–65

J. Khedari, S. Charoenvai, and J. Hirunlabh, New Insulating Particleboards from Durian Peel and Coconut Coir, Build. Environ., 2003, 38, p 435–441

H. Zhou, B. Li, and G. Huang, Sound Absorption Characteristics of Polymer Microparticles, J. Appl. Polym. Sci., 2006, 101, p 2675–2679

C. Zwikker and C.W. Kosten, Sound Absorbing Materials, Elsevier, New York, 1949

C.D. Li, Z.F. Chen, J.M. Zhou, B.B. Li, W.P. Wu, Z. Chen, T.Z. Xu, and J.L. Qiu, Material Parameter Determination in Glass Wool Mat for Sound Absorption, Appl. Mech. Mater., 2012, 148, p 1271–1275

F. Cotana, and M. Goretti, Energetic and Environmental Certification of Building Materials, Proceedings of the 1st International Congress on Built Environment and Sustainable Development-ACDES, 2008, p 6–14

C.N. Wang and J.H. Torng, Experimental Study of the Absorption Characteristics of Some Porous Fibrous Materials, Appl. Acoust., 2001, 62, p 447–459

M.J. Swift, P. Bris, and K.V. Horoshenkov, Acoustic Absorption in Re-cycled Rubber Granulate, Appl. Acoust., 1999, 57, p 203–212

M. Dogan and M. Alkan, Some Physicochemical Properties of Perlite as an Adsorbent, Fresenius Environ. Bull., 2004, 13, p 251–257

P.W. Harben and R.L. Bates, Industrial Minerals Geology and World Deposits, Metal Bulletin, London, 1990, p 184

S.A. Suvorov and V.V. Skurikhin, Vermiculite—A Promising Material for High-Temperature Heat Insulators, Refract. Ind. Ceram., 2003, 44, p 186–193

H. Benkreira, A. Khan, and K.V. Horoshenkov, Sustainable Acoustic and Thermal Insulation Materials from Elastomeric Waste Residues, Chem. Eng. Sci., 2011, 66, p 4157–4171

J.P. Arenas and M.J. Crocker, Recent Trends in Porous Sound-Absorbing Materials, Sound Vib., 2010, 44, p 12–18

GB/T 16731-1997, The Gradation of Sound Absorption Property for Absorbent Products, 1997

D. Murugan, S. Varughese, and T. Swaminathan, Recycled Polyolefin-Based Plastic Wastes for Sound Absorption, Polym-Plast. Technol., 2006, 45, p 885–888

R. Maderuelo-Sanz, A.V. Nadal-Gisbert, J.E. Crespo-Amoros, and F. Parres-Garcia, A Novel Sound Absorber with Recycled Fibers Coming from End of Life Tires (ELTs), Appl. Acoust., 2012, 73, p 402–408

M. Hosseini Fouladi, M. Ayub, and M. Jailani Mohd Nor, Analysis of Coir Fiber Acoustical Characteristics, Appl. Acoust., 2011, 72, p 35–42

X. Zhou, F. Zheng, H. Li, and C. Lu, An Environment-Friendly Thermal Insulation Material from Cotton Stalk Fibers, Eng. Build., 2010, 42, p 1070–1074

Acknowledgments

This research was funded by the National Natural Science Foundation of China (50974009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, Z., Shen, Z., Ma, S. et al. Novel Application of Glass Fibers Recovered From Waste Printed Circuit Boards as Sound and Thermal Insulation Material. J. of Materi Eng and Perform 22, 3140–3146 (2013). https://doi.org/10.1007/s11665-013-0587-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0587-y