Abstract

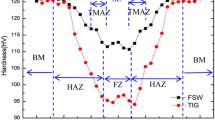

A new Al-Zn-Mg-Sc-Zr alloy with low Sc content was welded by tungsten inert gas (TIG) and friction stir welding (FSW) techniques. The microstructure and properties of those two welded joints were investigated by property tests and microstructural observations. The results show that the new Al-Zn-Mg-Sc-Zr alloy has desirable welding property. The ultimate tensile strength and welding coefficient of the TIG joint reach 405 MPa and 76.7%, respectively, and in FSW joint those property values reach 490 MPa and 92.6%, respectively. The studied base metal has a deformed fibrous subgrains structure, many nano-scaled Al3(Sc,Zr) particles, and very fine aging precipitates. In the TIG joint, the fusion zone consists of coarsened dendritic grains and the heat-affected zone (HAZ) has fibrous micro-scaled subgrains. The FSW welded joint is characterized by a weld nugget zone, thermo-mechanically affected zone (TMAZ), and HAZ. Due to plastic deformation around the rotating pin and anti-recrystallized effectiveness of Al3(Sc,Zr) particles, the weld nugget zone has a very fine subgrain structure. The TMAZ experiences some dissolution of aging precipitates. Coarsening of aging precipitates was observed in the HAZ. The better mechanical properties of the FSW joint are derived from a fine subgrain structure and homogeneous chemical compositions.

Similar content being viewed by others

References

J.C. Williams and E.A. Starke, Jr., Progress in Structural Materials for Aerospace Systems, Acta Mater., 2003, 51, p 5775–5799 (in English)

A. Heinz, A. Haszler, C. Keidel, S. Moldenhauer, R. Benedictus, and W.S. Miller, Recent Development in Aluminium Alloys for Aerospace Applications, Mater. Sci. Eng. A, 2000, 280, p 102–107 (in English)

S.K. Panigrahi and R. Jayaganthan, Effect of Ageing on Microstructure and Mechanical Properties of Bulk, Cryorolled, and Room Temperature Rolled Al 7075 Alloy, J. Alloys Compd., 2011, 509, p 9609–9616 (in English)

R.K.R. Singh, C. Sharma, D.K. Dwivedi, N.K. Mehta, and P. Kumar, The Microstructure and Mechanical Properties of Friction Stir Welded Al-Zn-Mg Alloy in as Welded and Heat Treated Conditions, Mater. Des., 2011, 32, p 682–687 (in English)

A.K. Mukhopadhyay, A. Kumar, S. Raveendra, and I. Samajdar, Development of Grain Structure During Superplastic Deformation of an Al-Zn-Mg-Cu-Zr Alloy Containing Sc, Scr. Mater., 2011, 64, p 386–389 (in English)

K.E. Knipling, D.N. Seidman, and D.C. Dunand, Ambient- and High-temperature Mechanical Properties of Isochronally Aged Al-0.06Sc, Al-0.06Zr and Al-0.06Sc-0.06Zr (at.%) Alloys, Acta Mater., 2011, 59, p 943–954 (in English)

M.E. van Dalen, T. Gyger, D.C. Dunand, and D.N. Seidman, Effects of Yb and Zr Microalloying Additions on the Microstructure and Mechanical Properties of Dilute Al-Sc Alloys, Acta Mater., 2011, 59, p 7615–7626 (in English)

V.G. Davydov, V.I. Elagin, V.V. Zakharov, and T.D. Rostova, Alloying Aluminum Alloys with Scandium and Zirconium Additives, Met. Sci. Heat Treat., 1996, 38, p 347–352 (in English)

Y. Deng, Z.M. Yin, K. Zhao, J.Q. Duan, and Z.B. He, Effects of Sc and Zr Microalloying Additions on the Microstructure and Mechanical Properties of New Al-Zn-Mg Alloys, J. Alloys Compd., 2012, 530, p 71–80 (in English)

Y. Deng, Z.M. Yin, K. Zhao, J.Q. Duan, J. Hu, and Z.B. He, Effects of Sc and Zr Microalloying Additions and Aging Time at 120 °C on the Corrosion Behaviour of an Al-Zn-Mg Alloy, Corros. Sci., 2012, 65, p 288–298 (in English)

Y. Deng, Z.M. Yin, K. Zhao, J.Q. Duan, B. Tang, and Z.B. He, Evolution of Microstructure and Properties in a New Type 2 mm Al-Zn-Mg-Sc-Zr Alloy Sheet, J. Alloys Compd., 2012, 517, p 118–126 (in English)

A. Squillace, A. De Fenzo, G. Giorleo, and F. Bellucci, A Comparison Between FSW and TIG Welding Techniques: Modifications of Microstructure and Pitting Corrosion Resistance in AA 2024-T3 Butt Joints, J. Mater. Process. Technol., 2004, 152, p 97–105 (in English)

S.W. Xu and X.M. Deng, A Study of Texture Patterns in Friction Stir Welds, Acta Mater., 2008, 56, p 1326–1341

R.S. Mishra and Z.Y. Ma, Friction Stir Welding and Processing, Mater. Sci. Eng. R, 2005, 50, p 1–78 (in English)

W.M. Thomas, E.D. Nicholas, J.C. Needham, M.G. Murch, P. Templesmith, and C.J. Dawes, G.B. Patent Application No. 9125978.8, Dec 1991

C.B. Fuller, J.L. Murray, and D.N. Seidman, Temporal Evolution of the Nanostructure of Al(Sc,Zr) Alloys: Part I—Chemical Compositions of Al3(Sc1_xZrx) Precipitates, Acta Mater., 2005, 53, p 5401–5413 (in English)

C.B. Fuller and D.N. Seidman, Temporal Evolution of the Nanostructure of Al(Sc,Zr) Alloys: Part II-Coarsening of Al3(Sc1_xZrx) Precipitates, Acta Mater., 2005, 53, p 5415–5428 (in English)

A. Tolley, V. Radmilovic, and U. Dahmen, Segregation in Al3(Sc,Zr) Precipitates in Al-Sc-Zr Alloys, Scr. Mater., 2005, 52, p 621–625 (in English)

Z.B. He, Y.Y. Peng, Z.M. Yin, and X.F. Lei, Comparison of FSW and TIG Welded Joints in Al-Mg-Mn-Sc-Zr Alloy Plates, Trans. Nonferr. Met. Soc. Chin., 2011, 21, p 1685–1686 (in English)

A. Cabello Munoz, G. Ruckert, B. Huneaua, X. Sauvageb, and S. Maryaa, Comparison of TIG Welded and Friction Stir Welded Al-4.5Mg-0.26Sc Alloy, J. Mater. Process. Technol, 2008, 197, p 337–343 (in English)

S. Dev, A.A. Stuart, R.C. Ravi Dev Kumaar, B.S. Murty, and K.P. Rao, Effect of Scandium Additions on Microstructure and Mechanical Properties of Al-Zn-Mg Alloy Welds, Mater. Sci. Eng. A, 2007, 467, p 132–138 (in English)

L.M. Wu, W.H. Wang, Y.F. Hsub, and S. Trong, Effects of Homogenization Treatment on Recrystallization Behavior and Dispersoid Distribution in an Al-Zn-Mg-Sc-Zr Alloy, J. Alloys Compd., 2008, 456, p 163–169 (in English)

A. Kverneland, V. Hansen, G. Thorkildsen, H.B. Larsen, P. Pattison, X.Z. Li, and J. Gjønnes, Transformations and Structures in the Al-Zn-Mg Alloy System: A Diffraction Study Using Synchrotron Radiation and Electron Precession, Mater. Sci. Eng. A, 2011, 528, p 880–887 (in English)

M.W. Mahoney, C.G. Rhodes, J.G. Flintoff, R.A. Spurling, and W.H. Bingel, Properties of Friction Stir Welded 7075-T651 Aluminum, Metall. Mater. Trans. A, 1998, 29, p 1955–1964 (in English)

Acknowledgments

The authors gratefully acknowledge the financial support from the National General Pre-research Project of China (51312010402).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Lei, X., Deng, Y., Peng, Y. et al. Microstructure and Properties of TIG/FSW Welded Joints of a New Al-Zn-Mg-Sc-Zr Alloy. J. of Materi Eng and Perform 22, 2723–2729 (2013). https://doi.org/10.1007/s11665-013-0577-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0577-0