Abstract

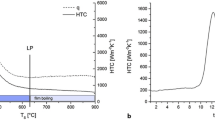

Quenching by spray cooling in the press line is a promising way to harden Al-Mg-Si alloys with regard to reducing profile distortion. For alloys such as EN AW-6082, high cooling rates are required. A device for spray cooling by means of water and compressed air was integrated into a 10 MN horizontal, hydraulic, short-stroke extrusion press. Various spray parameters were investigated. By using 32 water-air nozzles having a total water deposition rate of about 15 L/min and extruding with a profile velocity of 2.5 m/min, high mechanical properties were imparted to 30 mm diameter extruded rods. This arrangement ensures the extruded alloy is cooled to almost room temperature. Comparable properties can be achieved by water quenching, although the water consumption will be tenfold higher. The distribution of water deposition density on the profiles’ surfaces was determined. It was shown that an adjustment of the water-air pressure ratio allows the final temperature of the profiles to be controlled over a wide range. Minimization of temperature gradients in the cross section of complex profiles allows profile distortions to be reduced.

Similar content being viewed by others

References

N. Parson, J. Hankin, K. Hicklin, and C. Jowett, Comparison of the Extrusion Performance and Product Characteristics of Three Structural Extrusion alloys: AA6061, AA6082, and AA6005A, 7th International Aluminum Extrusion Technology Seminar Shaping the Future, May 16-19, 2000 (Chicago, Illinois), Aluminum Association, Vol II, p 1–12

S. Zajac, B. Bengtsson, C. Jonsson, and A. Isaksson, Quench Sensitivity of 6063 and 6082 Aluminum Alloys, 7th International Aluminum Extrusion Technology Seminar Shaping the Future, May 16-19, 2000 (Chicago, Illinois), Aluminum Association, Vol I, p 73–82

V.N. Ščerba, Pressovanie aljuminievych splavov (Extrusion of aluminium alloys), Intermet inžiniring, Moskva, 2001, in Russian

S. Kikuchi, M. Sukimoto, and K. Nakanishi, Analysis of Metal Flow and Recrystallization Behavior in Extrusion and Application of Results to Commercial Production, 4th International Aluminum Extrusion Technology Seminar Interactions, April 11-14, 1988 (Chicago, Illinois), Aluminum Association, Vol I, p 343–355

C. Kramer, Strangabkühlung (Cooling of extruded profiles), Strangpressen (Extrusion), J. Baumgarten, Ed., DGM-Informationsgesellschaftsverlag, 1990, p 119–138 (in German)

R. Jeschar, U. Reiners, and R. Scholz, Wärmeübergang bei der zweiphasigen Spritzwasserkühlung (Heat Transfer During Two Phase Splash Water Cooling), Wärme Gas Int., Vol 6/7 (No. 33), 1984, p 299–308 (in German)

N. Järvstråt and S. Tjøtta, A Process Model for On-line Quenching of Aluminium Extrusions, Metall. Mater. Trans. B, 1996, 3(27), p 501–508

D.D. Hall, I. Mudawar, R.E. Morgan, and S.L. Ehlers, Validation of Systematic Approach to Modeling Spray Quenching of Aluminium Alloy Extrusions, Composites and Continuous Castings, J. Mater. Eng. Perform., 1977, 1(6), p 77–92

D.H. Bratland, Ø. Grong, H. Shercliff, O.R. Myhr, and S. Tøtta, Modelling of Precipitation Reactions in Industrial Processing, Acta Mater., 1997, 1(45), p 1–22

M. Reich, S. Schöne, O. Keßler, M. Nowak, O. Grydin, F. Nürnberger, and M. Schaper, Simulation of Gas and Spray Quenching During Extrusion of Aluminium Alloys, Key Eng. Mater., Vol 424, 2010, p 57–64

A. Golovko, D. Rodman, F. Nürnberger, M. Schaper, Y. Frolov, and S. Bieliaiev, Investigation of the Water-Air Cooling Process of the Thick-Walled Extruded Profile Made of Alloy EN AW-6060 on the Output Table, Metall. Min. Ind., 2012, 2(4), p 66–74

V. Danchenko, O. Golovko, S. Belyaev, M. Schaper, and M. Nowak, Extrusion and Air-Water Cooling of AlSi1MgMn Alloy Extruded Profiles, Metall. Min. Ind., Vol 5 (No. 2), 2010, p 355–362

A. Grydin, O. Golovko, V. Danchenko, and M. Nowak, Vliânie parametrov processa prâmogo pressovaniâ na temperaturu profilej iz alûminievogo splava AA6060 (The Influence of Direct Extrusion Process Parameters on the Temperature of Profile of Aluminium Alloy AA6060), Metall. Min. Ind., 2006, 6(240), p 39–42 (in Russian)

Katalog 70, Spraying Systems Deutschland GmbH, Hamburg, Germany, 2012, p F28 (in German)

I. Frolov, T. Gretzki, Z. Yu, F. Nürnberger, T. Hassel, and Fr-W Bach, Surface Hardening Spline Geometries of Heat-Treatable Steel Cf53 using Water-Air Spray Cooling, Mater. Work. Press., 2009, 1(20), p 270–275

Vollkegeldüsen, Lechler GmbH, Metzingen, Germany, 2012, p 3.9 (in German)

F. Puschmann, “Experimentelle Untersuchung der Spraykühlung zur Qualitätsverbesserung durch definierte Einstellung des Wärmeübergangs,” Dissertation Thesis, Otto-von-Guericke-Universität Magdeburg, 2003

D. Jenista, Progressive Quenching: A New Approach to Distortion Control, 9th International Aluminum Extrusion Technology Seminar Billet and Extrusion The World of Ideas, May 13-16, 2008 (Orlando, Florida), Extrusion Technology for Aluminium Profiles Foundation, Vol I, p 393–401

A.N. Anderson, Physical Metallurgy and Extrusion of 6063 Alloy, Conference Proceedings of 5th International Aluminum Extrusion Technology Seminar Commitment to Excellence, May 19-22, 1992 (Chicago, Illinois), Aluminum Association, Vol I, p 43–56

R.C. Dorward and C. Bouvier, A Rationalization of Factors Affecting Strength, Ductility and Toughness of AA6061-Type Al-Mg-Si-(Cu) Alloys, Mater. Sci. Eng. A, 1998, 1–2(254), p 33–44

Y. Birol, The Effect of Processing and Mn Content on T5 andT6 Properties of AA6082 Profiles, J. Mater. Process. Technol., 2006, 1(173), p 84–91

R.C. Dorward, Preaging Effects in Al-Mg-Si Alloys Containing 0.6 to 0.9 Pct Mg2Si, Metall. Mater. Trans. B, 1973, 2(4), p 507–512

R.N. Wright, M. Usta, and S. Bartolucci, A Modern View of the Thermodynamics and Kinetics of the Magnesium Silicide Presence in 6xxx Alloys, 8th International Aluminum Extrusion Technology Seminar Exploring Innovations, May 18-21, 2004 (Orlando, Florida), Aluminum Extruders Council and the Aluminum Association, Vol II, p 67–75

F.O. Traenkner, Factors Affecting the Physical Characteristics of Aluminum-Magnesium-Silicon Alloy Extrusions, 2nd International Aluminum Extrusion Technology Seminar Billet and Extrusion, November 15-17, 1977 (Atlanta), Aluminum Association, Vol I, p 339–347

H. Hatta, S. Matsuda, and H. Yoshida, Two-Step Aging Behaviors of Al-Mg-Si Alloy Extrusions, 9th International Aluminum Extrusion Technology Seminar Billet and Extrusion the World of Ideas, May 13-16, 2008 (Orlando, Florida), Extrusion Technology for Aluminium Profiles Foundation, Vol I, p 425–430

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nowak, M., Golovko, O., Nürnberger, F. et al. Water-Air Spray Cooling of Extruded Profiles: Process Integrated Heat Treatment of the Alloy EN AW-6082. J. of Materi Eng and Perform 22, 2580–2587 (2013). https://doi.org/10.1007/s11665-013-0563-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0563-6