Abstract

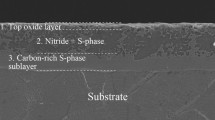

Liquid nitriding of type 321 austenite stainless steel was conducted at low temperature at 430 °C, using a type of a complex chemical heat-treatment; and the properties of the nitrided surface were evaluated. Experimental results revealed that a modified layer was formed on the surface with the thickness ranging from 2 to 30 μm varying with changing treatment time. When the stainless steel subjected to the advanced liquid nitriding less than 8 h at 430 °C, the main phase of the nitrided coating layer was the S phase generally. When the treatment time prolonged up to 16 h, S phase formed and partially transformed to CrN subsequently; and then the fine secondary CrN phase precipitated. All treatments performed in the current study can effectively improve the surface hardness. The nitrided layer thickness changed intensively with the increasing nitrided time. The growth of the nitride layer took place mainly by nitrogen diffusion according to the expected parabolic rate law. The highest hardness value obtained in this experiment was about 1400 Hv0.25. Low-temperature nitriding can improve the corrosion resistance of the 321 stainless steel against diluted vitriolic acid. The immerse test results revealed that the sample nitrided for 16 h had the best corrosion resistance than the others. SEM examinations indicated that after nitriding, the corrosion mechanisms of the steel had changed from serious general corrosion of untreated sample to selectivity corrosion of nitrided samples in the diluted vitriolic acid.

Similar content being viewed by others

References

H. Dong, S-phase Surface Engineering of Fe-Cr, Co-Cr and Ni-Cr Alloys, Int. Mater. Rev., 2010, 55, p 65

W. Jun, Z. Hong, W. Xiao-yong, and L. Cong, The Effect of Long-Term Isothermal Aging on Dynamic Fracture Toughness of Type 17-4 PH SS at 350 °C, Mater. Trans., 2005, 46, p 846

T.L. Christiansen and M.A.J. Somers, Controlled Dissolution of Colossal Quantities of Nitrogen in Stainless Steel, Metall. Mater. Trans. A., 2006, 37, p 675.

Y. Lin, L. Jian, L. Wang, X. Tao, and Q. Xue, Surface Nanocrystallization by Surface Mechanical Attrition Treatment and Its Effect on Structure and Properties of Plasma Nitrided AISI, 321 Stainless Steel, Acta Mater., 2006, 54, p 5599

T.S. Hummelshøj, T.L. Christiansen, and M.A.J. Somers, Lattice expansion of carbon-stabilized expanded austenite, Scripta Mater., 2010, 63, p 761

W. Liang, Surface Modification of AISI, 304 Austenitic Stainless Steel by Plasma Nitriding, Appl. Surf. Sci., 2003, 211, p 308

L. Wang, S. Ji, and J. Sun, Effect of Nitriding Time on the Nitrided Layer of AISI, 304 Austenitic Stainless Steel, Surf. Coat. Technol., 2006, 200, p 5067

R.B. Frandsen, T. Christiansen, and M.A.J. Somers, Simultaneous Surface Engineering and Bulk Hardening of Precipitation Hardening Stainless Steel, Surf. Coat. Technol., 2006, 200, p 5160

S. Sienz, S. Mandl, and B. Rauschenbach, In Situ Stress Measurements During Low-Energy Nitriding of Stainless Steel, Surf. Coat. Technol., 2002, 156, p 185

A.S. Hamdy, B. Marx, and D. Butt, Corrosion Behavior of Nitride Layer Obtained on AISI, 316L Stainless Steel via Simple Direct Nitridation Route at Low Temperature, Mater. Chem. Phys., 2011, 126, p 507

M. Kuczynska-Wydorska and J. Flis, Corrosion and Passivation of Low-Temperature Nitrided AISI, 304L and 316L Stainless Steels in Acidified Sodium Sulphate Solution, Corros. Sci., 2008, 50, p 523

H. Tsujimura, T. Goto, and Y. Ito, Surface Nitriding of SUS 304 Austenitic Stainless Steel by a Molten Salt Electrochemical Process, J. Electrochem. Soc., 2004, 151D, p 67

H. Tsujimura, T. Goto, and Y. Ito, Electrochemical Formation and Control of Chromium Nitride Films in Molten LiCl-KCl-Li3N Systems, Electrochim. Acta, 2002, 47, p 2725

K. Funatani, Low-Temperature Salt Bath Nitriding of Steels, Metal Sci. Heat Treat., 2004, 46, p 277

J.W. Zhang, L.T. Lu, K. Shiozawa, W.N. Zhou, and W.H. Zhang, Effect of Nitrocarburizing and Post-oxidation on Fatigue Behavior of 35CrMo Alloy Steel in Very High Cycle Fatigue Regime, Int. J. Fatigue, 2011, 33, p 880

P. Jacquet, J.B. Coudert, and P. Lourdin, How Different Steel Grades React to a Salt Bath Nitrocarburizing and Post-oxidation Process: Influence of Alloying Elements, Surf. Coat. Technol., 2011, 205, p 4064

Y.Z. Shen, K.H. Oh, and D.N. Lee, Nitriding of Steel in Potassium Nitrate Salt Bath, Scripta Mater., 2005, 53, p 1345

H. Tsujimura, T. Goto, and Y. Ito, Electrochemical Surface Nitriding of Pure Iron by Molten Salt Electrochemical Process, J. Alloys Compd., 2004, 376, p 246

H.Y. Li, D.F. Luo, C.F. Yeung, and K.H. Lau, Microstructural Studies of QPQ Complex Salt Bath Heat-Treated Steels, J. Mater. Process. Technol., 1997, 69, p 45

C.F. Yeung, K.H. Lau, H.Y. Li, and D.F. Luo, Advanced QPC Complex Salt Bath Heat Treatment, J. Mater. Process. Technol., 1997, 66, p 249

B. Larisch, U. Brusky, and H.J. Spies, Plasma Nitriding of Stainless Steels at Low Temperatures, Surf. Coat. Technol., 1999, 116-119, p 205

C.E. Foerster, F.C. Serbena, S.L.R. da Silva, C.M. Lepienski, C.J. de M. Siqueira, and M. Ueda, Mechanical and Tribological Properties of AISI, 304 Stainless Steel Nitrided by Glow Discharge Compared To Ion Implantation and Plasma Immersion Ion Implantation, Nucl. Instrum. Methods Phys. Res., Sect. B, 2007, 257, p 732

S.D. Chyou and H.C. Shih, The Effect of Nitrogen on the Corrosion of Plasma-Nitrided 4140 Steel, Corrosion, 1991, 47, p 31

C.X. Li and T. Bell, Corrosion Properties of Active Screen Plasma Nitrided 316 Austenitic Stainless Steel, Corros. Sci., 2004, 46, p 1527

E. Menthe and K.-T. Rie, Further Investigation of the Structure and Properties of Austenitic Stainless Steel after Plasma Nitriding, Surf. Coat. Technol., 1999, 116-119, p 199

I. Olefjord and L. Wegrelius, The Influence of Nitrogen on the Passivation of Stainless Steels, Corros. Sci., 1996, 38, p 1203–1220

H. Baba, T. Kodama, and Y. Katada, Role of Nitrogen on the Corrosion Behavior of Austenitic Stainless Steels, Corros. Sci., 2002, 44, p 2393

U. Kamachi Mudali, P. Shankar, S. Ningshen, R.K. Dayal, H.S. Khatak, and B. Raj, On the Pitting Corrosion Resistance of Nitrogen Alloyed Cold Worked Austenitic Stainless Steels, Corros. Sci., 2002, 44, p 2183

X. Xiaolei, W. Liang, Y. Zhiwei, and H. Zukun, A Comparative Study on Microstructure of the Plasma-Nitrided Layers on Austenitic Stainless Steel and Pure Fe, Surf. Coat. Technol., 2005, 192, p 220

Acknowledgments

The authors are very grateful to the National Natural Science Foundation of China (Grant No. 50901047) for financial support of this research work; and the author (J.W) would like to thank Prof. Luo Defu of Xihua University, People’s Republic of China, for his valuable discussions during the course of the research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, Y., Wang, J., Zeng, D. et al. Advance Complex Liquid Nitriding of Stainless Steel AISI 321 Surface at 430 °C. J. of Materi Eng and Perform 22, 2567–2573 (2013). https://doi.org/10.1007/s11665-013-0545-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0545-8