Abstract

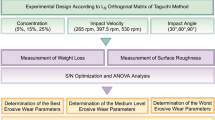

Nihard Grade-4, a nickel-bearing cast iron widely used in slurry pumps and hydrodynamic components, is evaluated for its erosive wear response under mining conditions using a statistical approach. Experiments were conducted by varying the factors namely velocity, slurry concentration, angle of impingement, and pH in three levels, using L9 orthogonal array. Analysis of variance was used to rank the factors influencing erosive wear. The results indicate that velocity is the most influencing factor followed by the angle of impingement, slurry concentration, and pH. Interaction effects of velocity, slurry concentration, angle of impingement, and pH on erosion rate have been discussed. Wear morphology was also studied using SEM characterization technique. At lower angle (30°) of impingement, the erosion of material is by micro fracture and shallow ploughing with the plastic deformation of the ductile austenitic matrix. At the normal angle (90°) of impingement, the material loss from the surface is found because of deep indentation, forming protruded lips which are removed by means of repeated impact of the erodent.

Similar content being viewed by others

References

B.D. Jana and M.M. Stack, Modelling Impact Angle Effects on Erosion-Corrosion of Pure Metals: Construction of Materials Performance Maps, Wear, 2005, 259, p 243–255

A.V. Levy, Solid Particle Erosion and Erosion-Corrosion of Materials, ASM International, Materials Park, OH, 1995

I. Finnie, Erosion of Surface by Solid Particles, Wear, 1960, 3, p 87–103

M.A. Al-Bukahiti, S.M. Ahmed, F.M.F. Badran, and K.M. Emara, Effect of Impingement Angle on Slurry Erosion Behaviour and Mechanisms of, Steel and High-Chromium White Cast Iron, Wear, 1017, 262(2007), p 1187–1198

H. Meng, X. Hu, and A. Neville, A Systematic Study of Two Stainless Steels in Marine Conditions via Experimental Design, Wear, 2007, 263, p 355–362

S.S. Rajahram, T.J. Harvey, and R.J.K. Wood, Full Factorial Investigation on the Erosion-Corrosion Resistance of UNS S31603, Tribol. Int., 2010, 43, p 2072–2083

J. Liu, S. Li, and Y. Man, Wear Resistance of M-hard 4 and High-Chromium Cast Iron Re-evaluated, Wear, 1993, 166, p 37–40

G. Davidson, Considerations for Proper Sizing and Materials Selection to Optimize Centrifugal Slurry Pump Performance, Proceedings of the Fourth International Pump Symposium, Turbomachinery Laboratories, Texas A & M University, 1987, p 35–54

K. Rohrig, Ni-Hard Material Data and Applications, Nickel Development Institute, Technology & Engineering, Toronto, 1996, p 1-28

ASM International, ASM Handbook of Microstructures and Metallography, ASM International, Materials Park, OH, 2004

M. Divakar, V.K. Agarwal, and S.N. Singh, Effect of the Material Surface Hardness on the Erosion of AISI, 316, Wear, 2005, 259, p 110–117

B.A. Lindsley and A.R. Marder, The Effect of Velocity on the Solid Particle Erosion Rate of Alloys, Wear, 1999, 225–229, p 510–516

J.K. Robert, Wood, Erosion-Corrosion Interactions and Their Effect on Marine and Offshore Materials, Wear, 2006, 261, p 1012–1023

M.M. Stack, J. Chacon-Nava, and F.H. Stott, Relationship Between the Effects of Velocity and Alloy Corrosion Resistance in Erosion-Corrosion Environments at Elevated Temperatures, Wear, 1995, 180, p 91–94

M.M. Stack, N. Corlettb, and S. Turgoose, Some Thoughts on Modelling the Effects of Oxygen and Particle Concentration on the Erosion-Corrosion of Steels in Aqueous Slurries, Wear, 2003, 255, p 225–236

S. Turenne, M. Fiset, and J. Masounave, The Effect of Sand Concentration on the Erosion of Materials by a Slurry Jet, Wear, 1989, 133, p 95–106

T. Manisekaran, M. Kamaraj, S.M. Sharrif, and S.V. Joshi, Slurry Erosion Studies on Surface Modified 13Cr-Ni Steels: Effect of Angle of Impingement and Particle Size, J. Mater. Eng. Perform., 2007, 16, p 567–572

H.M. Clark, The Influence of the Flow Field in Slurry Erosion, Wear, 1992, 152, p 223–240

B.K. Prasad, A.K. Jha, O.P. Modi, and A.H. Yegneswaran, Effect of Sand Concentration in the Medium and Travel Distance and Speed on the Slurry Wear Response of a Zinc-Based Alloy Alumina Particle Composite, Tribol. Lett., 2004, 17, p 301–309

S.G. Sapate and A.V. Ramo, Erosive Wear Behaviour of Weld Hardfacing High Chromium Cast Iron Effect of Erodent Particles, Tribol. Int., 2006, 39, p 206–212

S.G. Sapate and A.V. Ramo, Effect of Carbide Volume Fraction on Erosion Wear Behaviour of Hard Facing Cast Irons, Wear, 2004, 156, p 774–786

S. Chatterjee and T.K. Pal, Solid Particle Erosion Behaviour of Hardfacing Deposits on Cast Iron—Influence of Deposit Microstructure and Erodent Particles, Wear, 2006, 261, p 1069–1079

I. Finnie, Some Observations on the Erosion of Ductile Metals, Wear, 1972, 19, p 81–90

R.C. Shivamurthy, M. Kamaraj, R. Nagarajan, S.M. Shariff, and G. Padmanabham, Slurry Erosion Characteristics and Erosive Wear Mechanisms of Co-Based and Ni-Based Coatings Formed by Laser Surface Alloying, Metall. Mater. Trans A, 2010, 41A, p 470–486

A.K. Chauhan, D.B. Goel, and S. Prakash, Erosion Behaviour of Hydro Turbine Steels, Bull. Mater. Sci., 2008, 31, p 115–120

M. Duraiselvam, R. Galun, S. Siegmann, V. Wesling, and L. Mordike, Liquid Impact Erosion Characteristics of Martensitic Stainless Steel Laser Clad with Ni-Based Intermetallic Composites and Matrix Composites, Wear, 2006, 261, p 1140–1149

A.J. Ninham and A.V. Levy, The Erosion of Carbide-Metal Composites, Wear, 1988, 121, p 347–361

Acknowledgments

The authors wish to thank the management of the National Institute of Technology, Tiruchirappalli, India for having provided all the necessary facilities to carry out this study. The financial support for this work received from Neyveli Lignite Corporation Limited, Neyveli, India is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yoganandh, J., Natarajan, S. & Babu, S.P.K. Erosive Wear Behavior of Nickel-Based High Alloy White Cast Iron Under Mining Conditions Using Orthogonal Array. J. of Materi Eng and Perform 22, 2534–2541 (2013). https://doi.org/10.1007/s11665-013-0539-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0539-6