Abstract

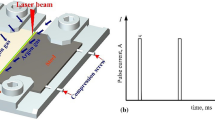

Welding of heterogeneous Ti-6Al-4V alloy and X5CrNi18-10 steel, using a continuous Nd:YAG laser was performed by inserting a 600-μm-thick Cu foil between the two components, thus enabling an improvement of the properties of the joint. The changes in the main laser welding parameters (power and speed), based on the microstructural observations and mechanical tests, show that the resulting properties are influenced by the nature and dimensions of the transitional zone between the unmelted Ti-6Al-4V and the melted bath, where the intermetallic phases accumulate.

Similar content being viewed by others

References

W.B. Lee and S.B. Jung, Effect of Microstructure on Mechanical Properties of Friction-Welded Joints between Ti and AISI, 321 Stainless Steel, Mater. Trans., 2004, 45(9), p 2805–2811

W.B. Lee, Y.J. Kim, and S.B. Jung, Effects of Copper Insert Layer on the Properties of Friction Welded Joints between TiAl and AISI4140 Structural Steel, Intermetallics, 2004, 12, p 671–678

S. Kundu, M. Ghosh, and S. Chatterjee, Diffusion Bonding of Commercially Pure Titanium and 17-4 Precipitation Hardening Stainless Steel, Mater. Sci. Eng., A, 2006, 428(1-2), p 18–23

H. Hiraga, K. Fukatsu, K. Ogawa, M. Nakayama, and Y. Muto, Nd:YAG Laser Welding of Pure Titanium to Stainless Steel, Weld. Res. Int., 2002, 16(8), p 623–631

C. Groza, I. Mitelea, and E. Dimian, Mechanical and Structural Characteristics of Friction Welded Ti-6Al-4V+X5CrNi18-10 Dissimilar Joints, Proc. of the 20th International Conference on Metallurgy and Materials, METAL 2011, May 18-20, Brno, Czech Republic, 2011, p 614–619

N. Kahraman, B. Gülenç, and F. Findik, Joining of Titanium/Stainless Steel by Explosive Welding and Effect on Interface, J. Mater. Process. Technol., 2005, 169(2), p 127–133

M. Gao, S.W. Mei, Z.M. Wang, X.Y. Li, and X.Y. Zeng, Characterisation of Laser Welded Dissimilar Ti/Steel Joint using Mg Interlayer, Sci. Technol. Weld. Joining, 2012, 17(4), p 269–276

V.V. Semak, W.D. Bragg, B. Damkroger, and S. Kempka, Transient Model for the Keyhole During Laser Welding, J. Phys. D Appl. Phys., 1999, 32, p L61–L64

M.Bass, E.W.Van Stryland, Eds., Handbook of Optics, vol. 2, McGraw-Hill, USA, 1994

R. Fabbro, S. Slimani, F. Coste, and F. Briand, Study on Keyhole Behavior for Full Penetration Nd:YAD CW Laser Welding, J. Phys. D Appl. Phys., 2004, 38, p 1881–1887

O.G. Bykovskiy, I.V. Tkachenko, Properties of Alloys Forming in Transition Zone of Welded Steel-Ti Joint, Avtomaticeskaia svarka, 1987, 9, p 414 (in Russian)

Acknowledgments

This study was also supported by a grant of the Romanian National Authority for Scientific Research, CNCS—UEFISCDI, project number PN-II-ID-PCE-2011-3-0837. The partial support from the Department of Interface and Reactivity in Materials, Interdisciplinary Laboratory Carnot of the University of Bourgogne is also acknowledged by C. Groza.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mitelea, I., Groza, C. & Craciunescu, C. Copper Interlayer Contribution on Nd:YAG Laser Welding of Dissimilar Ti-6Al-4V Alloy with X5CrNi18-10 Steel. J. of Materi Eng and Perform 22, 2219–2223 (2013). https://doi.org/10.1007/s11665-013-0507-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0507-1