Abstract

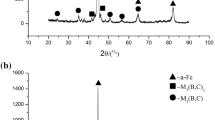

Microstructure, mechanical properties, and wear resistance of B-bearing high-speed steel (HSS) roll material containing 0.90-1.00% C, 1.3-1.5% B, 0.8-1.5% W, 0.8-1.5% Mo, 4.6-5.0% Cr, 1.0-1.2% V, and 0.15-0.20% Ti were studied by means of the optical microscopy (OM), the scanning electron microscopy (SEM), x-ray diffraction (XRD), hardness, impact toughness, and pin-on-disk abrasion tests. The results showed that as-cast structure of B-bearing HSS consisted of α-Fe-, M23(B,C)6-, M3(B0.7C0.3)-, and M2(B,C)-type borocarbides, a small quantity of retained austenite, and a small amount of TiC. The hardness and impact toughness values of as-cast B-bearing HSS reached 65-67 HRC and 80-85 kJ/cm2, respectively. There were many M23(B,C)6-precipitated phases in the matrix after tempering, and then, with increasing temperature, the amount of precipitated phases increased considerably. Hardness of B-bearing HSS gradually decreased with the increasing tempering temperature, and the change of tempering temperature had no obvious effect on impact toughness. B-bearing HSS tempered at 500 °C has excellent wear resistance, which can be attributed to the effect of boron.

Similar content being viewed by others

References

P.R. Da Mota, R.A. Goncalves, A.M. Reis, and M.B. Da Silva, Performance of High-Speed Steel Taps at High Cutting Speed, Int. J. Mach. Mach. Mater., 2007, 2(2), p 299–308

A.S. Chaus, M.V. Sitkevich, and P. Pokorný, Cutting Tests for End-Milling Radius Cutters of High-Speed Steel With and Without Diffusion Coating, J. Frict. Wear, 2010, 31(6), p 419–425

M. Andersson, R. Finnstrom, and T. Nylen, Introduction of Enhanced Indefinite Chill and High Speed Steel Rolls in European Hot Strip Mills, Ironmaking Steelmaking, 2004, 31(5), p 383–388

H.G. Fu, Y.H. Qu, J.D. Xing, X.H. Zhi, Z.Q. Jiang, M.W. Li, and Y. Zhang, Investigations on Heat Treatment of a High-Speed Steel Roll, J. Mater. Eng. Perform., 2008, 17(4), p 535–542

N.F. Garza-Montes-de-Oca and W.M. Rainforth, Wear Mechanisms Experienced by a Work Roll Grade High Speed Steel Under Different Environmental Conditions, Wear, 2009, 267(1-4), p 441–448

R.R. Xavier, M.A. de Carvalho, E. Cannizza, T.H. White, Jr., and A. Sinatora, High-Speed Steel Rolls for Long Products, Iron Steel Technol., 2004, 1(2), p 28–33

B.C. Hwang, D.W. Suh, and S.J. Kim, Austenitizing Temperature and Hardenability of Low-Carbon Boron Steels, Scr. Mater., 2011, 64(12), p 1118–1120

J.J. Zhang, Y.M. Gao, J.D. Xing, S.Q. Ma, D.W. Yi, L. Liu, and J.B. Yan, Effects of Plastic Deformation and Heat Treatment on Microstructure and Properties of High Boron Cast Steel, J. Mater. Eng. Perform., 2011, 20(9), p 1658–1664

J.W. Li, S. Zhang Guo, S.Z. Wei, and Q. Zhao, Preparation Technology of the Low Carbon High Boron Fe-C-B Wear Resistance Steel, Appl. Mech. Mater., 2011, 52-54, p 1718–1722

P.F. Wu, X.D. Liu, G.D. Che, Y. Lu, J.M. Wang, and J.F. Li, Effects of Heat-Treatment Process on Mechanical Properties and Microstructure of ZG30Cr2Mn2Si, Foundry China, 2008, 57, p 63–65

Z.Q. Jiang, H.G. Fu, J. Yang, and J.H. Wang, Effect of Quenching Temperature on Microstructure and Hardness of High Boron Cast Steel, Trans. Mater. Heat Treat., 2007, 28, p 158–160

K. Weber, D. Regener, H. Mehner, and M. Menzel, Characterization of the Microstructure of High-Chromium Cast Irons Using Mössbauer Spectroscopy, Mater. Charact., 2001, 46, p 399–406

C.P. Tabrett and I.R. Sare, The Effect of Heat Treatment on the Abrasion Resistance of Alloy White Irons, Wear, 1997, 203-204, p 206–219

L.E. Zevin and G. Kimmel, Quantitative X-Ray Diffractometry, Springer, New York, 1995

C.M. Kim, X-Ray Method of Measuring Retained Austenite in Heat Treated White Cast Irons, J. Heat. Treat., 1979, 1, p 43–51

F. Xiong, Metallography of X-Ray, Machinery Industry Press, Beijing, 1981

B. Wanzhen, W. Shizhong, L. Rui, X. Liujie, D. Zhanwu, and Y. Xiong, Effects of Retained Austenite on Rolling Wear Properties of High Vanadium High Speed Steel, Lubr. Eng., 2007, 32, p 66–72 (In Chin.)

Measurement of Retained Austenite in the Steel—X-ray Diffractometer Method. GB8362-1987.

Q.S. Luo, J.P. Xie, and Y.P. Song, Effects of Microstructures on the Abrasive Wear Behaviour of Spheroidal Cast Iron, Wear, 1995, 184(1), p 1–10

H.G. Fu, Q. Xiao, and J.D. Xing, A Study of Microstructure and Performance of Tempered Fe-V-W-Mo Alloy, Steel Res. Int., 2006, 77(2), p 139–143

J.D. Xing, W.H. Lu, and X.T. Wang, Proceedings of International Conference on Wear of Materials, Reston, VA, April 11-14, 1983, K.C. Ludema, Ed., ASME, New York, 1983, p 45

H.M. Wang and J.L. Ji, Wear Behaviour of CTC I, FeCrCSi Composite, Chin. J. Met. Sci. Technol., 1990, 6, p 357–364

A.Y. Mosbah, D. Wexler, and A. Calka, Abrasive Wear of WC-FeAl Composites, Wear, 2005, 258, p 1337–1341

G. Abbas and U. Ghazanfar, Two-Body Abrasive Wear Studies of Laser Produced Stainless Steel and Stainless Steel + SiC Composite Clads, Wear, 2005, 258, p 258–264

H.G. Fu, Y.P. Lei, J.D. Xing, and L.M. Huang, Investigations on Microstructures and Properties of B containing Cast Steel for Wear Resistance Applications, Ironmaking Steelmaking, 2008, 35(5), p 371–378

H.M. Wang, Q. Zhang, and H.S. Shao, Two-Body Abrasive Wear Behaviour of Austempered Steel, Wear Theory and Anti-Wear Technology, F.Y. Lin, Ed., Science Press, Beijing, 1993, p 162–165

C.K. Kim, D.G. Lee, and S. Lee, Correlation of Microstructure and Fracture Properties of Five Centrifugal Cast High Speed Steel Rolls, Mater. Sci. Technol., 2007, 23(9), p 1065–1074

X. Li, Z. Du, H. Fu, Z. Feng, and H. Zhao, Experimental Investigation on Heat Treatment of a High-Speed Steel for Hot Rolling Roll Mill, Materialwiss. Werkstofftech., 2010, 41(3), p 170–176

H. Baker, Alloy Phase Diagrams, vol. 3 of ASM Handbook, ASM International, Materials Park, OH, 1992, p 281

A.S. Chaus, Modifying Cast Tungsten-Molybdenum High-Speed Steels with Niobium, Zirconium, and Titanium, Met. Sci. Heat Treat., 2005, 47(1-2), p 53–61

A.S. Chaus and F.I. Rudnitskii, Effect of Modification on the Structure and Properties of Cast Tungsten-Molybdenum High-Speed Steels, Met. Sci. Heat Treat., 1989, 31(1-2), p 121–128

S. Kheirandish, Effect of Ti and Nb on the Formation of Carbides and the Mechanical Properties in As-Cast AISI-M7 High-Speed Steel, ISIJ Int., 2001, 41, p 1502–1509

S. Kheirandish, S. Mirdamadi, and Y.H.K. Kharrazi, Effect of Titanium on Cast Structure of High Speed Steel, Mater. Sci. Technol., 1998, 14, p 312–316

H.G. Fu, D.M. Fu, D.N. Zou, and J.D. Xing, Structures and Properties of High-Carbon High Speed Steel by RE-Mg-Ti Compound Modification, J. Wuhan Univ. Technol. Mater. Sci. Ed., 2004, 19(2), p 48–51

D. Turnbull and B. Vonnegut, Nucleation Catalysis, Ind. Eng. Chem., 1952, 44(6), p 1292–1298

B.L. Bramfitt, Planar Lattice Disregistry Theory and Its Application on Heterogistry Nuclei of Metal, Metall. Trans., 1970, 1(7), p 1987–1995

M.M. Khruschov, The Effect of Wear on the Compressive Stress in the Sphere on Plane Configuration, Wear, 1974, 28, p 69–78

S. Hesheng and Z. Qing, Abrasive Wear of Metal and Wear-Resistant Materials, Machinery Industry Press, Beijing, 1988

Acknowledgments

The authors would like to acknowledge the financial support for this study from the National Natural Science Foundation of China under grant (51274016) and the Scientific Plan Item of Beijing Education Committee under grant (PXM2012-136, PXM2012-156).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fu, H., Ma, S., Hou, J. et al. Microstructure and Properties of Cast B-Bearing High Speed Steel. J. of Materi Eng and Perform 22, 1194–1200 (2013). https://doi.org/10.1007/s11665-012-0378-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-012-0378-x