Abstract

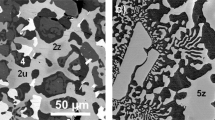

Nickel-based alloys are being considered as candidate materials for the storage of high level waste. In the present investigation, Alloy 600 was assessed by potentiodynamic anodic polarization technique for its corrosion behavior in the as-received, solution annealed, and sensitized condition in 3 M HNO3 and 3 M HNO3 containing simulated high level waste. From the results of the investigation, it was found that the solution annealed specimen possesses superior corrosion resistance compared to the as-received and sensitized specimen. Double loop electrochemical potentiokinetic reactivation test was carried out to study the degree of sensitization. The effect of different concentrations of chloride ions in 3 M HNO3 at 25 °C indicated tendency for pitting as the concentration of chloride ions was increased. Microstructural examination was carried out by optical microscope and scanning electron microscope after electrolytic etching. X-ray photoelectron spectroscopy study was carried out to investigate the passive film formed in 3 M HNO3 and 3 M HNO3 simulated high level waste.

Similar content being viewed by others

References

L. Vehovar and M. Tandler, Stainless Steel Containers for the Storage of Low and Medium Level Radioactive Waste, Nucl. Eng. Des., 2001, 206(1), p 21–33

P.K. Samantaroy, S. Girija, R. Paul, U. Kamachi Mudali, and Baldev Raj, Corrosion Behavior of Alloy 690 and Alloy 693 in Simulated Nuclear High Level Waste Medium, J. Nucl. Mater., 2011, 418(1–3), p 27–37

R.B. Rebak and P. Crook, Nickel Alloys for Corrosive Environments, Adv. Mater. Process., 2000, 157(2), p 37–42

A.J. Bard, J. Jordan, and R. Parsons, Standard Potentials in Aqueous Solutions, Marshal Dekker, New York, 1985

G.S. Was, Grain-Boundary Chemistry and Intergranular Fracture in Austenitic Nickel-Base Alloys—A Review, Corrosion, 1990, 46(4), p 319–330

G. Dominguez-Sanchez, C.G. Tiburcio, F.M. Almeraya-Calderon, and A. Martinez-Villafane, Electrochemical Study About Microorganisms Induced Corrosion in Inconel, Port. Electrochim. Acta, 2005, 23(1), p 47–53

J.D. Kim and J.H. Moon, C-ring Stress Corrosion Test for Inconel 600 and Inconel 690 Sleeve Joint Welded by Nd:YAG Laser, Corros. Sci., 2004, 46(4), p 807–818

Y.S. Lim, H.P. Kim, J.H. Han, J.S. Kim, and H.S. Kwon, Influence of Laser Surface Melting on the Susceptibility to Intergranular Corrosion of Sensitized Alloy 600, Corros. Sci., 2001, 43(7), p 1321–1335

C.B. In, S.P. Kim, Y.I. Kim, W.W. Kim, I.H. Kuk, S.S. Chun, and W.J. Lee, Pitting Resistance of TiN Deposited on Inconel 600 by Plasma-Assisted Chemical Vapor Deposition, J. Nucl. Mater., 1994, 211(3), p 223–230

G.P. Airey, Effect of Processing Variables on the Caustic Stress Corrosion Resistance of Inconel Alloy 600, Corrosion, 1980, 36(1), p 9–17

S. Takaya, T. Suzuki, T. Uchimoto, and K. Miya, Magnetic Force Microscopy Observation of Sensitized Inconel 600, J. Appl. Phys., 2002, 91(10), p 7011–7013

S. Girija, V.R. Raju, U. Kamachi Mudali, and R.K. Dayal, Corrosion Assessment of Type 304L Stainless Steel in Nitric Acid, Corros. Eng. Sci. Technol., 2003, 38(4), p 309–312

S. Girija, U. Kamachi Mudali, V. Shankar, and R.K. Dayal, Microstructure and Pitting Corrosion Aspects of As-weld and Thermally Aged 316 Stainless Steel SMA Weld Deposits Containing Different Nitrogen Contents, Trans. Indian Inst. Met., 2002, 55(5), p 439–446

D.R. Johns and F.R. Beckitt, Factors Influencing the Thermal Stabilisation of Alloy 600 Tubing Against Intergranular Corrosion, Corros. Sci., 1990, 30(2–3), p 223–237

Y.S. Sato, P. Arkom, H. Kokawa, T.W. Nelson, and R.J. Steel, Effect of Microstructure on Properties of Friction Stir Welded Inconel Alloy 600, Mater. Sci. Eng., A, 2008, 477(12), p 250–258

M. Casales, V.M. Salinas-Bravo, A. Martinez-Villafane, and J.G. Gonzalez-Rodriguez, Effect of Heat Treatment on the Stress Corrosion Cracking of Alloy 690, Mater. Sci. Eng., A, 2002, 332(1–2), p 223–230

M.K. Ahn, H.S. Kwon, and J.H. Lee, Predicting Susceptibility of Alloy 600 to Intergranular Stress Corrosion Cracking Using a Modified Electrochemical Potentiokinetic Reactivation Test, Corrosion, 1995, 51(6), p 441–449

M. Shimada, H. Kokawa, Z.J. Wang, Y.S. Sato, and I. Karibe, Optimization of Grain Boundary Character Distribution for Intergranular Corrosion Resistant 304 Stainless Steel by Twin-Induced Grain Boundary Engineering, Acta Mater., 2002, 50(9), p 2331–2341

F. Balboud, G. Sanchez, P. Fauvet, G. Santarini, and G. Picard, Mechanism of Corrosion of AISI, 304L Stainless Steel in the Presence of Nitric Acid Condensates, Corros. Sci., 2000, 42(10), p 1685–1707

S. Ningshen, U. Kamachi Mudali, G. Amarendra, and Baldev Raj, Corrosion Assessment of Nitric Acid Grade Austenitic Stainless Steels, Corros. Sci., 2009, 51(2), p 322–329

D.G. Kolman, D.K. Ford, D.P. Butt, and T.O. Nelson, Corrosion of 304 Stainless Steel Exposed to Nitric Acid-Chloride Environments, Corros. Sci., 1997, 39(12), p 2067–2093

M.G. Fontana, Corrosion Engineering, McGraw Hill, New York, 1986, p 26

Acknowledgments

The authors would like to acknowledge Prof. Ramesh Chandra, IIT, Roorkee and Mr. B. Shashank Dutt of Materials Development and Technology Group, IGCAR for the help in SEM observation of the specimens. Also, thanks to Mr. T. Nandakumar of Corrosion Science & Technology Group, IGCAR for the technical support in carrying out the specimen preparation for the polarization tests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Samantaroy, P.K., Suresh, G., Krishna, N.G. et al. Corrosion Behavior of Alloy 600 in Simulated Nuclear High Level Waste Medium. J. of Materi Eng and Perform 22, 1041–1053 (2013). https://doi.org/10.1007/s11665-012-0345-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-012-0345-6