Abstract

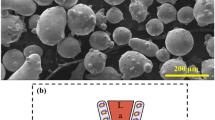

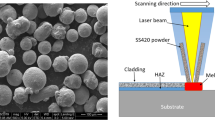

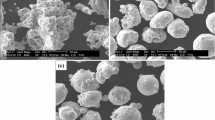

Laser cladding of tungsten carbide (WC) on stainless steels 13Cr-4Ni and AISI 304 substrates has been performed using high power diode laser. The cladded stainless steels were characterized for microstructural changes, hardness, solid particle erosion resistance and corrosion behavior. Resistance of the clad to solid particle erosion was evaluated using alumina particles according to ASTM G76 and corrosion behavior was studied by employing the anodic polarization and open circuit potential measurement in 3.5% NaCl solution and tap water. The hardness of laser cladded AISI 304 and 13Cr-4Ni stainless steel was increased up to 815 and 725Hv100 g, respectively. The erosion resistance of the modified surface was improved significantly such that the erosion rate of cladded AISI 304 (at 114 W/mm2) was observed ~0.74 mg/cm2/h as compared to ~1.16 and 0.97 mg/cm2/h for untreated AISI 304 and 13Cr-4Ni, respectively. Laser cladding of both the stainless steels, however, reduced the corrosion resistance in both NaCl and tap water.

Similar content being viewed by others

References

G.I. Nikitenko, Studies to Reduce Cavitation Erosion of the Impellers in the Hydro Turbines at the Sayano-Shushenskoe Hydroelectric Plant, Hydrotech. Construct., 1998, 32, p 570–573

C.J. Heathcock, B.E. Protheroe, and A. Ball, Cavitation Erosion of Stainless Steels, Wear, 1982, 81, p 311–327

R. Singh, S.K. Tiwari, and S.K. Mishra, Cavitation Erosion in Hydraulic Turbine Components and Mitigation by Coatings: Current Status and Future Needs, J. Mater. Eng. Perform., 2012. doi:10.1007/s11665-011-0051-9

D.H. Graham and A. Bell, Particle Erosion of Candidate Materials for Hydraulic Valves, Wear, 1989, 133, p 125–132

B.S. Mann and V. Arya, HVOF Coating and Surface Treatment for Enhancing Droplet Erosion Resistance of Steam Turbine Blades, Wear, 2003, 254, p 652–668

D. Toma, W. Brandl, and G. Marginean, Wear and Corrosion Behaviour of Thermally Sprayed Cermet Coatings, Surf. Coat. Technol., 2001, 138, p 149–158

Y.P. Kathuria, Some Aspects of Laser Surface Cladding in the Turbine Industry, Surf. Coat. Technol., 2000, 132, p 262–269

F.T. Cheng, C.T. Kwok, and H.C. Man, Laser Surfacing of SS31603 Stainless Steel with Engineering Ceramics for Cavitation Erosion Resistance, Surf. Coat. Technol., 2001, 139, p 14–24

P. Wu, H.M. Du, X.L. Chen, Z.Q. Li, H.L. Bai, and E.Y. Jian, Influence of WC Particle Behavior on the Wear Resistance Properties of Ni-WC Composite Coatings, Wear, 2004, 257, p 142–147

M. Riabkina-Fishman, E. Rabkin, P. Levin, N. Frage, M.P. Dariel, A. Weisheit, R. Galun, and B.L. Mordike, Laser Produced Functionally Graded Tungsten Carbide Coatings on M2 High-Speed Tool Steel, Mater. Sci. Eng. A, 2001, 302, p 106–114

J. Przybyłowicz and J. Kusiński, Structure of Laser Cladded Tungsten Carbide Composite Coatings, J. Mater. Process. Technol., 2001, 109, p 154–160

C.P. Paul, H. Alemohammad, E. Toyserkani, A. Khajepour, and S. Corbin, Cladding of WC-12 Co on Low Carbon Steel Using a Pulsed Nd:YAG Laser, Mater. Sci. Eng. A, 2007, 464, p 170–176

Y. Yang and H.C. Man, Microstructure Evolution of Laser Clad Layers of W-C-Co Alloy Powders, Surf. Coat. Technol., 2000, 132, p 130–136

M. Zhong, W. Liu, Y. Zhang, and X. Zhu, Formation of WC/Ni Hard Alloy Coating by Laser Cladding of W/C/Ni Pure Element Powder Blend, Int. J. Refract. Met. Hard Mater., 2006, 24, p 453–460

A. Hidouci, J.M. Pelletier, F. Ducoin, D. Dezert, and R. El Guerjouma, Microstructural and Mechanical Characteristics of Laser Coatings, Surf. Coat. Technol., 2000, 123, p 17–23

K. Van Acker, D. Vanhoyweghen, R. Persoons, and J. Vangrunderbeek, Influence of Tungsten Carbide Particle Size and Distribution on the Wear Resistance of Laser Clad WC/Ni Coatings, Wear, 2005, 258, p 194–202

H. Chen, C. Xu, J. Qu, I.M. Hutchings, P.H. Shipway, and J. Liu, Sliding Wear Behaviour of Laser Clad Coatings Based Upon a Nickel-Based Self-Fluxing Alloy Co-deposited with Conventional and Nanostructured Tungsten Carbide-Cobalt Hardmetals, Wear, 2005, 259, p 801–806

V.K. Nanda, Parameters Affecting Abrasion and Remedial Measures, Proceedings of 1st International Conference on Silting Problems in Hydro Power Plants, 1999, New Delhi, India, p 43–52

H.S. Sidhu, B.S. Sidhu, and S. Prakash, Solid Particle Erosion of HVOF Sprayed NiCr and Stellite-6 Coatings, Surf. Coat. Technol., 2007, 202, p 232–238

C. Monticelli, A. Frignani, and F. Zucchi, Investigation on the Corrosion Process of Carbon Steel Coated by HVOF WC/CO Cermets in Neutral Solution, Corros. Sci., 2004, 46, p 1225–1237

A.M. Human and H.E. Exner, The Relationship Between Electrochemical Behaviour and In-Service Corrosion of WC Based Cemented Carbides, Int. J. Refract. Met. Hard Mater., 1997, 15, p 65–71

J.D. Voorhies, Electrochemical and Chemical Corrosion of Tungsten Carbide (WC), J. Electrochem. Soc., 1972, 119, p 219–222

M. Metikos-Hukovic and R. Babic, Passivation and Corrosion Behaviors of Cobalt and Cobalt-Chromium-Molybdenum Alloy, Corros. Sci., 2007, 49, p 3570–3579

W.J. Tomlinson and C.R. Linzell, Anodic Polarisation and Corrosion of Cemented Carbides with Cobalt and Nickel Binders, J. Mater. Sci., 1988, 23, p 914–918

Acknowledgments

The work carried out in this paper is part of a supra institutional project SIP0025. Help rendered by Shri Rajesh Jha in carrying out some laser cladding and erosion experiments is sincerely acknowledged.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Singh, R., Kumar, M., Kumar, D. et al. Erosion and Corrosion Behavior of Laser Cladded Stainless Steels with Tungsten Carbide. J. of Materi Eng and Perform 21, 2274–2282 (2012). https://doi.org/10.1007/s11665-012-0170-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-012-0170-y