Abstract

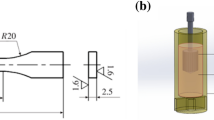

Flow stress characteristic of 1235 aluminum alloy treated by different purification methods was studied by dynamic thermo-simulation test. The effects of oxide inclusions on steady flow stress, peak stress, and true strain corresponding to peak stress were also examined in this study. The results showed that there is a steady flow feature in 1235 aluminum alloy during hot compression deformation. 1235 aluminum alloy with lower inclusion content shows higher strength, therefore, the plasticity and toughness are better and improve the hot-working character of the alloy. Therefore, reducing inclusion content is effective for improving the hot deformation character of aluminum foil (1235 aluminum alloy).

Similar content being viewed by others

References

M. Zhou, D. Shu, L. Li, and W.Y. Zhang, Performance Improvement of Industrial Pure Aluminum Treated by Stirring Molten Fluxes, Mater. Sci. Eng. A, 2003, 347, p 280–290

G.S. Fu, W.Z. Chen, and K.W. Qian, Behavior of Flow Stress of Aluminum Sheets Used for Pressure Can during Compression at Elevated Temperature, Acta Metall. Sin., 2005, 18, p 756–763

Y.L. Chen, G.S. Fu, and W.Z. Chen, Influence of Melt-Treatment on Material Constants of Aluminum Sheet Used for Easy-Open Can During Hot Deformation, Trans. Nonferrous Met. Soc. China, 2006, 16, p 304–310

G.S. Fu, W.Z. Chen, and K.W. Qian, Effects of Melt-Treatment Technique on the Metallurgical Quality and Mechanical Properties of Al Sheet Used for Can Manufacture, Key Eng. Mater., 2005, 297, p 482–488

G.S. Fu, F.S. Sun, L.Y. Ren, W.Z. Chen, and K.W. Qian, Modification Behavior of Trace Rare Earth on Impurity Phases in Commercial Purity Aluminum, J. Rare Earths, 2002, 20, p 61–66

S.O. Poulsen, E.M. Lauridsen, and A. Lyckegaard, In Situ Measurements of Growth Rates and Grain-Averaged Activation Energies of Individual Grains During Recrystallization of 50% Cold-Rolled Aluminium, Scr. Mater., 2011, 64, p 1003–1006

X.Y. Liu, Q.L. Pan, Y.B. He, W.B. Li, W.J. Liang, and Z.M. Yin, Flow Behavior and Microstructural Evolution of Al-Cu-Mg-Ag Alloy During Hot Compression Deformation, Mater. Sci. Eng. A, 2009, 500, p 150–154

S. Gourdet and F. Montheillet, An Experimental Study of Recrystallization Mechanism During Hot Deformation of Aluminum, Mater. Sci. Eng. A, 2000, 283, p 274–288

J.D. Robson, D.T. Henry, and B. Davis, Particle Effects on Recrystallization in Magnesium–Manganese Alloys: Particle-Stimulated Nucleation, Acta Mater., 2009, 57, p 2739–2747

Y. Deng, Z.M. Yin, and J.W. Huang, Hot Deformation Behavior and Microstructural Evolution of Homogenized 7050 Aluminum Alloy During Compression at Elevated Temperature, Mater. Sci. Eng. A, 2011, 528, p 1780–1786

J. Zhang, F.S. Pan, R.L. Zuo, and C.G. Bai, The Low Temperature Precipitation in Commercial-Purity Aluminium Sheets for Foils, J. Mater. Process. Technol., 2008, 206, p 382–387

Acknowledgment

The authors acknowledge with gratitude the financial support received from the Fujian Natural Science Foundation (E0610004), China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yan, W., Fu, G., Chen, H. et al. Effects of Oxide Inclusions on Flow Stress Behavior of 1235 Aluminum Alloy During Hot Compression. J. of Materi Eng and Perform 21, 2203–2206 (2012). https://doi.org/10.1007/s11665-012-0152-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-012-0152-0