Abstract

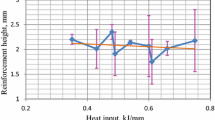

Welding parameters have direct effects on the bead geometry, microstructure, and mechanical properties of low alloy steels. A series of experiments have been carried out to examine some of these parameters using the flux cored arc welding process (FCAW). In this article, an experimental study was conducted to investigate the influence of welding parameters in FCAW process particularly welding voltage and travel speed on weld bead dimensions. The study also includes the effects of bead overlap and deposition sequence on the parent material and the heat-affected zone (HAZ) properties. It was found that an increase in the welding voltage leads to an increase in the weld bead width, and the increase in the welding traverse speed leads to a decrease in the weld bead width. When studying the bead overlap percentages, it was found that the 50% bead overlap can be considered to be practically a better option than the higher percentages of bead overlap (i.e., 70-90%). The experimental investigation of studying the deposition sequence showed that there were no significant differences in the microstructure, hardness, and the size of the refined HAZ between the two proposed deposition sequences. However, a significant improvement in the microstructure and the size of the refined HAZ, and a reduction in the hardness were achieved after depositing the second welding bead, irrespective of the depositing sequence.

Similar content being viewed by others

References

K.C. Mitchell, The Applications of Flux Cored Arc Welding (FCAW) in UK Power Plant, OMMI, 2003, 2(1), p 7

K.C. Mitchell, Repair Welding in the Power Industry Using Cored Wires, Proceedings of the 1998 1st IEE/IMechE International Conference on Power Station Maintenance—Profitability Through Reliability, Mar 30-Apr 1, 1998 (Edinburgh, UK) IEE, Stevenage, England, 1998

A. Aloraier, A. Al-Mazrouee, J.W.H. Price, and T. Shehata, Weld Repair Practices Without Post Weld Heat Treatment for Ferritic Alloys and Their Consequences on Residual Stresses: A Review, Int. J. Pres. Ves. Pip., 2010, 87(4), p 127–133

A. Aloraier, R. Ibrahim, and P. Thomson, FCAW Process to Avoid the Use of Post Weld Heat Treatment, Int. J. Pres. Ves. Pip., 2006, 83(5), p 394–398

A.S. Aloraier, R.N. Ibrahim, and J. Ghojel, Eliminating Post-Weld Heat Treatment in Repair Welding by Temper Bead Technique: Role Bead Sequence in Metallurgical Changes, J. Mater. Process. Technol., 2004, 153–154, p 392–400

K. Ishizaki, Interfacial Tension Theory of the Phenomenon of Arc Welding-Mechanism of Penetration, Proceeding of Symposium on Physics of Arc Welding, The Institute of Welding, London, 1962, p 195–209

K. Ishizaki, On the Formation of the Weld Bead, Proceeding of Symposium on Physics of Arc Welding, The Institute of Welding, London, 1962, p 155–157

A. Shumovsky, Controlling Welding Shrinkage and Distortion, The Canadian Welder, 1952, p 179–180

M.A. Aesh, Optimization of Weld Bead Dimensions in GTAW of Aluminum-Magnesium Alloy, Mater. Manuf. Process., 2001, 16(5), p 725–736

V. Dey, D.K. Pratihar, G.L. Datta, M.N. Jha, T.K. Saha, and A.V. Bapat, Optimization of Bead Geometry in Electron Beam Welding Using a Genetic Algorithm, J. Mater. Process. Technol., 2009, 209(3), p 1151–1157

P. Sathiya, S. Aravindan, A.N. Haq, and K. Paneerselvam, Optimization of Friction Welding Parameters Using Evolutionary Computational Techniques, J. Mater. Process. Technol., 2009, 209(5), p 2576–2584

V.K. Goyal, P.K. Ghosh, and J.S. Saini, Analytical Studies on Thermal Behaviour and Geometry of Weld Pool in Pulsed Current Gas Metal Arc Welding, J. Mater. Process. Technol., 2009, 209(3), p 1318–1336

K.Y. Benyounis and A.G. Olabi, Optimization of Different Welding Processes Using Statistical and Numerical Approaches—A Reference Guide, Adv. Eng. Softw., 2008, 39(6), p 483–496

V. Gunaraj and N. Murugan, Prediction and Comparison of the Area of the Heat-Affected Zone for the Bead-on-Plate and Bead-on-Joint in Submerged Arc Welding of Pipes, J. Mater. Process. Technol., 1999, 95(1–3), p 246–261

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aloraier, A., Almazrouee, A., Shehata, T. et al. Role of Welding Parameters Using the Flux Cored Arc Welding Process of Low Alloy Steels on Bead Geometry and Mechanical Properties. J. of Materi Eng and Perform 21, 540–547 (2012). https://doi.org/10.1007/s11665-011-9948-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-011-9948-6