Abstract

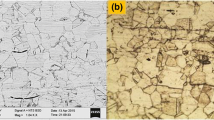

This article presents the comparative evaluation of microstructural features and mechanical properties of friction stir welded (solid-state) and laser beam welded (high energy density fusion welding) AISI 409M grade ferritic stainless steel joints. Optical microscopy, microhardness testing, transverse tensile, and impact tests were performed. The coarse ferrite grains in the base material were changed to fine grains consisting duplex structure of ferrite and martensite due to the rapid cooling rate and high strain induced by severe plastic deformation caused by frictional stirring. On the other hand, columnar dendritic grain structure was observed in fusion zone of laser beam welded joints. Tensile testing indicates overmatching of the weld metal relative to the base metal irrespective of the welding processes used. The LBW joint exhibited superior impact toughness compared to the FSW joint.

Similar content being viewed by others

References

AISI 409M—Technical Data. 2004. Detail brochure published by SAIL, India.

R.H. Kalthauser, Improving the Engineering Properties of Stainless Steels, Source Book on the Ferritic Stainless Steel, ASM Engineering Bookshelf, American Society for Metals, 1982, p 212–218

M. Du Toit and J. Naude, The Influence of Stabilization with Titanium on the Heat Affected Zone Sensitization of 11 to 12% Chromium Ferritic Stainless Steels Under Low Heat Input Welding Conditions, 2009, IIW Doc. IX-H-705-09, p 1–12.

E. Taban, E. Deleu, A. Dhooge, and E. Kaluc, Laser Welding of Modified 12% Cr Stainless Steel: Strength, Fatigue, Toughness, Microstructure and Corrosion Properties, Mater. Des., 2009, 30, p 1193–1200

M.L.Greef, “The Influence of Welding Parameters on the Sensitisation Behaviour of 3CR12,” M.S. Thesis, University of Pretoria, 2006.

M. Van Warmelo, D. Nolan, and J. Norrish, Mitigation of Sensitisation Effects in Unstabilised 12% Cr Ferritic Stainless Steel Welds, Mater. Sci. Eng. A, 2007, 464, p 157–169

A.M. Meyer, “Interstitial Diffusion from the Weld Metal into the High Temperature Heat Affected Zone in 11–12 Percent Chromium Steel Welded Joints,” ME Thesis. University of Pretoria, South Africa, 2000.

M. Penasa and C. Rivela, Application of the Laser Welding Process to Low Thickness Stainless Steels, Weld. Int., 2003, 17, p 947–957

H. Lee and J.L. Wu, The Effects of Peak Temperature and Cooling Rate on the Susceptibility to Intergranular Corrosion of Alloy 690 by Laser Beam and Gas Tungsten Arc Welding, Corros. Sci., 2009, 51, p 439–445

J. Kell, J.R. Tyrer, R.L. Higginson, and R.C. Thomson, Microstructural Characterization of Autogenous Laser Welds on 316L Stainless Steel Using EBSD and EDS, J. Microsc., 2005, 217, p 167–173

W.M. Thomas, E.D.Nicholas, J.C. NeedHam, M.G. Murch, P. Templesmith, and C.J. Dawes. Friction Stir Welding. International Patent Application No. PCT/GB92102203 and Great Britain Patent Application No. 9125978; 1991.

L. Zhou, H.J. Liu, and Q.W. Liu, Microstructural Characteristics and Mechanical Properties of Friction Stir Welded Joints of Ti–6Al–4V Titanium Alloy, Mater. Des., 2010, 31, p 2631–2636

S. Packer, T. Nelson, C.D. Sorensen, R. Steel, and M. Matsunaga. Tool and Equipment Requirements for Friction Stir Welding Ferrous and Other High Melting Temperature Alloys, 4th Int Friction Stir Welding Symp, Park City, Utah, USA, in CD-ROM, 2003 (not paginated).

C.D. Sorensen, T.W. Nelson, and S.M. Packer, Tool Material Testing for FSW of High-Temperature Alloys, Proceedings of the Third International Symposium on Friction Stir Welding, Sept 2001 (Kobe, Japan), TWI, paper on CD.

A.P. Reynolds, W. Tang, M. Posada, and J. Deloach, Friction Stir Welding of DH36 Steel, Sci. Technol. Weld. Join., 2003, 8, p 455–460

M. Collier, R. Steel, T. Nelson, C. Sorensen, and S. Packer, Grade Development of Polycrystalline Cubic Boron Nitride for Friction Stir Processing of Ferrous Alloys, Mater. Sci. Forum, 2003, 426–432, p 3011–3016

S.H.C. Park, T. Kumagai, Y.S. Sato YS, H. Kokawa, K.Okamoto, S. Hirano, and M. Inagaki, Microstructure and Mechanical Properties of Friction Stir Welded 430 Stainless Steel, Proceedings of The Fifteenth (2005) International Offshore and Polar Engineering Conference, Seoul, Korea, June 19-24, 2005.

A.K. Lakshminarayanan and V. Balasubramanian, An assessment of Microstructure Hardness, Tensile and Impact Strength of Friction Stir Welded Ferritic Stainless Steel Joints, Mater. Des., 2010, 31, p 4592–4600

L. Wanga, C.J. Song, F.M. Sun, L.J. Li, and Q.J. Zhai, Microstructure and Mechanical Properties of 12 wt.% Cr Ferritic Stainless Steel with Ti and Nb Dual Stabilization, Mater. Des., 2009, 30, p 49–56

C. Meadows and J.D. Fritz, Understanding Stainless Steel Heat Affected Zones, Weld. J., 2005, 84, p 25–30

K. Shanmugam, A.K. Lakshminarayanan, and V. Balasubramanian, Tensile and Impact Properties of Shielded Metal Arc Welded Ferritic Stainless Steel Joints, J. Mater. Sci. Technol., 2009, 45, p 181–186

E. Taban, E. Deleu, A. Dhooge, and E. Kaluc, Gas Metal Arc Welding of Modified X2CrNi12 Ferritic Stainless Steel Kovove, Mater. Metall. Mater., 2007, 45, p 67–73

ASTM International Standard E8M-04, Standard Test Methods for Tension Testing of Metallic Materials.

ASTM International Standard E23-06, Standard Test Methods for Notched Bar Impact Testing of Metallic Materials.

ASTM International Standard E 407-99 Standard Practices for Microetching Metals and Alloys.

M. Tullmin, F.P.A. Robinson, C.A.O. Henning, A. Strauss, and J.L. Grange, Properties of Laser-Welded and Electron-Beam Welded Ferritic Stainless Steel, Johannesb. S. Afr. Inst. Min. Metall., 1989, 89, p 243–249

G. Madhusudan Reddy and K. Srinivasa Rao, Microstructure and Mechanical Properties of Similar and Dissimilar Stainless Steel Electron Beam and Friction Welds, Int. J. Adv. Manuf. Technol., 2009, 45, p 875–888

R. Kaul, P. Ganesh, A.K. Nath, P. Triapthi, and R.V. Nandedkar, Characterization and Comparison of Laser and Gas Tungsten Arc Weldments of AISI, 430 Stainless Steel, Met. Mater. Process., 2002, 14(1), p 41–48

R.G. Campbell, Ferritic Stainless Steel Welding Metallurgy, Eng. Mater., 1992, 69(70), p 167–216

J.J. Demo, Structure and Constitution of Wrought Ferritic Stainless Steels in Handbook of Stainless Steels, D. Peckner and I.M. Benstein, Ed., McGraw-Hill Book Company, New York, 1977, p 5.1–5.40.

J.C. Lippold and D.J. Kotecki, Welding Metallurgy and Weldability of Stainless Steels, Wiley, Hoboken, NJ, 2005

M.C. Balmforth and J.C. Lippold, A New Ferritic–Martensitic Stainless Steel Constitution Diagram, Weld. J., 2000, 77, p 1s–7s

G. Madhusudhan Reddy and T. Mohandas, Explorative Studies on Grain Refinement of Ferritic Stainless Steel Welds, J. Mater. Sci. Lett., 2001, 20, p 721–723

S.J. Hales and T.R. McNelley, Microstructural Evolution by Continuous Recrystallization in a Superplastic Al–Mg Alloy, Acta Metall., 1988, 36, p 1229–1239

K.V. Jata and S.L. Semiatin, Continuous Dynamic Recrystallization During Friction Stir Welding of High Strength Aluminum Alloys, Scripta Mater., 2000, 43, p 743–749

A. Belyakov, Y. Kimura, and K. Tsuzaki, Microstructure Evolution in Dual Phase Stainless Steel During Severe Deformation, Acta Mater., 2006, 54, p 2521–2532

M. Topic, C. Allen, and R. Tait, The Effect of Cold Work and Heat Treatment on the Fatigue Behavior of 3Cr12 Corrosion-Resistant Steel Wire, Int. J. Fatigue, 2007, 29, p 49–56

H.W. Hayden and S. Floreen, The Influence of Martensite and Ferrite on the Properties of Two Phase Stainless Steels Having Microduplex Microstructures, Metall. Trans., 1950, 1, p 1955–1959

R.N. Wright and J.R. Wood, Fe-Cr-Mn Micro-Duplex Ferritic Martensitic Stainless Steels, Metall. Trans., 1977, 8A, p 1977–2007

Acknowledgments

The authors are grateful to Dr. G. Padmanbam, Scientist ‘F’ and Mr. N. Shanmugarajan, Scientist ‘D’ of Centre for Laser Processing of Materials (CLPM), International Advanced Research Centre for powder metallurgy & New materials, Hyderabad 500 005, Andhra Pradesh, India for their support and guidance in fabricating LBW joints.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lakshminarayanan, A.K., Balasubramanian, V. Characteristics of Laser Beam and Friction Stir Welded AISI 409M Ferritic Stainless Steel Joints. J. of Materi Eng and Perform 21, 530–539 (2012). https://doi.org/10.1007/s11665-011-9943-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-011-9943-y