Abstract

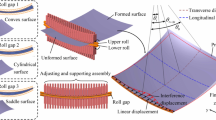

In this research, the wire drawing process with flat roller dies is investigated. A prototypal apparatus is developed to conduct experimental tests on such a process and analyze the influence of main roll drawing parameters (e.g., incoming wire diameter, forming rolls diameter, thickness reduction, and friction conditions) on geometrical characteristics of flattened wires. A finite element model (FEM) is developed to simulate the deformation of the wire during the process. Within the entire range of experiments, a good agreement between experimental data and numerical results is found which allows validating the FE model. A further observation from the experimental program and numerical simulations is that a complicated dependence of the lateral spread of wire and width of contact area on process parameters exists during wire drawing with roller dies.

Similar content being viewed by others

References

B. Carlsson and J. Lagergren, The Deformation of Drawn Wire in Flat Rolling, Proc. ESDA 96, Third Biennial Joint Conf. on Eng. Syst. Design and Analysis, Vol 3, ASME, New York, 1996, p 175–180

B. Carlsson, The Contact Pressure Distribution in Flat Rolling of Wire, J. Mater. Process. Technol., 1998, 73, p 1–6

M. Kazeminezhad and A. Karimi Taheri, A Theoretical and Experimental Investigation on Wire Flat Rolling Process Using Deformation Pattern, J. Mater. Des., 2005, 26, p 99–103

M. Kazeminezhad and A. Karimi Taheri, The Prediction of Macroscopic Shear Bands in Flat Rolled Wire Using the Finite and Slab Element Method, Mater. Lett., 2006, 60, p 3265–3268

M. Kazeminezhad and A. Karimi Taheri, Deformation Inhomogeneity in Flattened Copper Wire, J. Mater. Des., 2007, 28, p 2047–2053

C. Vallellano, P.A. Cabanillas, and F.J. Garcia-Lomas, Analysis of Deformations and Stresses in Flat Rolling of Wire, J. Mater. Process. Technol., 2008, 195, p 63–71

J.W. Pilarczyk, H. Dyja, B. Golis, and E. Tabuda, Effect of Roller Dies Drawing on Structure, Texture and Other Properties of High Carbon Steel Wires, Met. Mater., 1998, 4, p 727–731

J.W. Pilarczyk, P. Van Houtte, and E. Aernoudt, Effect of Hydrodynamic and Roller Die Drawing on the Texture of High Carbon Steel Wires, Int. J. Mater. Sci. Eng. A, 1995, 197, p 97–101

J. Luksza and M. Burdek, The Influence of the Deformation Mode on the Final Mechanical Properties of Products in Multi-Pass Drawing and Flat Rolling, J. Mater. Process. Technol., 2002, 125–126, p 725–730

L.S. Bayoumi, Round-to-Square Section Drawing Through Flat Idle Rolls, Int. J. Mech. Sci., 1999, 41, p 1323–1338

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lambiase, F., Di Ilio, A. Experimental and Finite Element Investigation of Roll Drawing Process. J. of Materi Eng and Perform 21, 161–166 (2012). https://doi.org/10.1007/s11665-011-9932-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-011-9932-1