Abstract

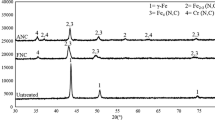

Plasma nitrocarburizing treatments of AISI 4140 low alloy steel have been carried out in a gas mixture of 85% N2-12% H2-3% CO2. All treatments were performed for 5 h at a chamber pressure of 4 mbar. Different treatment temperatures varying from 520 to 620 °C have been used to investigate the effect of treatment temperature on the corrosion and hardness properties and also microstructure of the plasma nitrocarburized steel. Scanning electron and optical microscopy, x-ray diffraction, microhardness measurement, and potentiodynamic polarization technique in 3.5% NaCl solution were used to study the treated surfaces. The results revealed that plasma nitrocarburizing at temperatures below 570 °C can readily produce a monophase ε compound layer. The compound layer formed at 620 °C is composed of two sub-layers and is supported by an austenite zone followed by the diffusion layer. The thickest diffusion layer was related to the sample treated at 620 °C. Microhardness results showed a reduction of surface hardness with increasing the treatment temperature from 520 to 620 °C. It has also been found that with increasing treatment temperature from 520 to 545 °C the corrosion resistance increases up to a maximum and then decreases with further increasing treatment temperature from 545 to 620 °C.

Similar content being viewed by others

References

T. Malinava, S. Malinov, and N. Pantev, Simulation of Microhardness Profiles for Nitrocarburized Surface Layers by Artificial Neural Network, Surf. Coat. Technol., 2001, 135(2–3), p 258–267

A. Suhadi, C.X. Li, and T. Bell, Austenitic Plasma Nitrocarburising of Carbon Steel in N2–H2 Atmosphere with Organic Vapour Additions, Surf. Coat. Technol., 2006, 200, p 4397–4405

T. Bell, Y. Sun, and A. Suhadi, Environmental and Technical Aspects of Plasma Nitrocarburizing, Vacuum, 2000, 59, p 14–23

D. Oliveira, A.P. Tschiptschin, and C.E. Pinedo, Simultaneous Plasma Nitriding and Ageing Treatments of Precipitation Hardenable Plastic Mould Steel, Mater. Des., 2007, 28, p 1714–1718

T. Bell, M. Kinali, and G. Munstermann, Physical Metallurgy Aspects of the Austenitic Nitrocarburising Process, Heat Treat. Met., 1987, 2, p 47–51

M. Karakan, A. Alsaran, and A. Celik, Effect of Process Time on Structural and Tribological Properties of Ferritic Plasma Nitrocarburized AISI, 4140 Steel, Mater. Des., 2004, 25, p 349–353

I. Lee, Plasma Post Oxidation of Nitrocarburized AISI, 4140 Steel, Rare Met., 2006, 25, p 267–271

E. Haruman, T. Bell, and Y. Sun, The Compound Layer Characteristics Resulting from Plasma Nitrocarburizing with an Atmosphere Containing CO2 Gas Additions, Surf. Eng., 1993, 3, p 121–140

B. Edenhofer, Physical and Metallurgical Aspects of Ion Nitriding, Heat Treat. Met. 2, 1974, 1, p 59–67

F. Mahboubi and K. Abdolvahabi, The Effect of Temperature of Plasma Nitriding Behavior of DIN 1.6959 Low Alloy Steel, Vacuum, 2006, 81, p 239–243

S. Li, R.R. Manory, and J.H. Hensler, Compound Layer Growth and Compound Layer Porosity of Austenite Plasma Nitrocarburized Non-Alloyed Steel, Surf. Coat. Technol., 1995, 71, p 112–120

G.E. Totten and A.H. Hawes Maurice, Steel Heat Treatment Handbook, 2nd ed., Taylor and Francis Group, New York, 2007

D.A. Porter and K.E. Easterling, Phase Transformation in Metals and Alloys, VNB, UK, 1983

R.S.E. Schneider and H. Hiebler, Influence of Increased Nitriding Temperatures on the Hardness Profile of Low-Alloy Steels, J. Mater. Sci., 1998, 33, p 1737–1744

M. Fattah and F. Mahboubi, Comparison of Ferritic and Austenitic Plasma Nitriding and Nitrocarburizing Behavior of AISI, 4140 Low Alloy Steel, Mater. Des., 2010, 31, p 3915–3921

C. Dawes, D.F. Tranter, and C.G. Smith, Reappraisal of Nitrocarburizing and Nitriding When Applied to Design and Manufacture of Non-Alloy Steel Automobile Components, J. Heat Treat., 1979, 1(2), p 30–42

A. Basu, J. Dutta Majumdar, J. Alphonsa, S. Mukherjee, and I. Manna, Corrosion Resistance Improvement of High Carbon Low Alloy Steel by Plasma Nitriding, Mater. Lett., 2008, 62, p 3117–3120

R. Winston Revie and H.H. Uhlig, Corrosion and Corrosion Control, 4th ed., Wiley, Hoboken, NJ, 2008

D.C. Wen, Microstructure and Corrosion Resistance of the Layers Formed on the Surface of Precipitation Hardenable Plastic Mold Steel by Plasma-Nitriding, Appl. Surf. Sci., 2009, 256, p 797–804

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fattah, M., Mahboubi, F. Microstructure Characterization and Corrosion Properties of Nitrocarburized AISI 4140 Low Alloy Steel. J. of Materi Eng and Perform 21, 548–552 (2012). https://doi.org/10.1007/s11665-011-9922-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-011-9922-3