Abstract

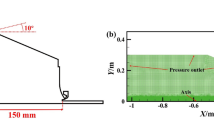

Aluminum powder in tube compaction with a 25 mm front plug through equal channel angular extrusion (ECAE) at room temperature was modeled using the finite element analysis package ABAQUS. The Gurson model was used in modeling this process. 2-D simulations in a 90° angle die showed better consolidation of powder near the inner edge of the die than the outer edge after one pass of ECAE but almost full densification occurs after two passes. The effect of hydrostatic pressure on densification of the powder was investigated by using two plugs varying in length dimension. The results obtained from the simulations were also compared with experiments conducted to compact aluminum powder with mean particle diameter of 45 μm. Optical microscopy, microhardness test, and density measurements confirmed the simulations. The simulations were extended to powder compaction in a 60° and 120° angle die. It was found that one pass of ECAE is sufficient to consolidate the aluminum powder completely and uniformly in a 60° angle die, whereas the material is still porous in a 120° angle die.

Similar content being viewed by others

References

V.M. Segal, Materials Processing by Simple Shear, Mater. Sci. Eng. A, 1995, 197, p 157–164

Y. Iwahashi, Z. Horita, M. Nemoto, and T.G. Langdon, An Investigation of Microstructural Evolution During Equal-Channel Angular Pressing, Acta Mater., 1997, 45, p 4733–4741

Y. Iwahashi, Z. Horita, M. Nemoto, and T.G. Langdon, Factors Influencing the Equilibrium Grain Size in Equal-Channel Angular Pressing: Role of Mg Additions to Aluminum, Metall. Mater. Trans. A, 1998, 29, p 2503–2512

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov, Bulk Nanostructured Materials From Severe Plastic Deformation, Prog. Mater. Sci., 2000, 45, p 103–110

V.M. Segal, Equal Channel Angular Extrusion: From Macromechanics to Structure Formation, Mater. Sci. Eng. A, 1999, 271, p 322–333

V.M. Segal, Engineering and Commercialization of Equal Channel Angular Extrusion (ECAE), Mater. Sci. Eng. A, 2004, 386, p 269–276

Y.T. Zhu and T.C. Lowe, Observations and Issues on Mechanisms of Grain Refinement During ECAP Process, Mater. Sci. Eng. A, 2000, 291, p 46–53

R. Srinivasan, Computer Simulation of the Equal Channel Angular Extrusion (ECAE) Process, Scr. Mater., 2001, 44, p 91–96

T. Suo, Y. Li, Y. Guo, and Y. Liu, The Simulation of Deformation Distribution During ECAP Using 3D Finite Element Method, Mater. Sci. Eng. A, 2006, 432, p 269–274

I. Balasundar, M. Sudhakara Rao, and T. Raghu, Equal Channel Angular Pressing Die to Extrude a Variety of Materials, Mater. Des., 2009, 30, p 1050–1059

S. Xu, G. Zhao, G. Ren, and X. Ma, Numerical Simulation and Experimental Investigation of Pure Copper Deformation Behavior for Equal Channel Angular Pressing/Extrusion Process, Comput. Mater. Sci., 2008, 44, p 247–252

A.V. Nagasekhar and Y. Tick-Hon, Optimal Tool Angles for Equal Channel Angular Extrusion of Strain Hardening Materials by Finite Element Analysis, Comput. Mater. Sci., 2004, 30, p 489–495

P. Leo, E. Cerri, P.P. De Marco, and H.J. Roven, Properties and Deformation Behaviour of Severe Plastic Deformed Aluminum Alloys, J. Mater. Process. Technol., 2007, 182, p 207–214

A.V. Nagasekhar, Y. Tick-Hon, and H.P. Seow, Deformation Behavior and Strain Homogeneity in Equal Channel Angular Extrusion/Pressing, J. Mater. Process. Technol., 2007, 192–193, p 449–452

B.S. Moon, H.S. Kim, and S.I. Hong, Plastic Flow and Deformation Homogeneity of 6061 Al During Equal Channel Angular Pressing, Scr. Mater., 2002, 46, p 131–136

C.J. Luis Perez, P. Gonzales, and Y. Garces, Channel Angular Extrusion in a Commercial Al-Mn Alloy, J. Mater. Process. Technol., 2003, 143–144, p 506–511

G.M. Stoica, D.E. Fielden, R. McDaniels, Y. Liu, B. Huang, P.K. Liaw, C. Xu, and T.G. Langdon, An Analysis of the Shear Zone for Metals Deformed by Equal-Channel Angular Processing, Mater. Sci. Eng. A, 2005, 410–411, p 239–242

S. Li, M.A.M. Bourke, I.J. Beyerlein, D.J. Alexander, and B. Clausen, Finite Element Analysis of the Plastic Deformation Zone and Working Load in Equal Channel Angular Extrusion, Mater. Sci. Eng. A, 2004, 382, p 217–236

J.Y. Suh, H.S. Kim, J.W. Park, and J.Y. Chang, Finite Element Analysis of Material Flow in Equal Channel Angular Pressing, Scr. Mater., 2001, 44, p 677–681

S.J. Oh and S.B. Kang, Analysis of the Billet Deformation During Equal Channel Angular Pressing, Mater. Sci. Eng. A, 2003, 343, p 107–115

S.W. Chung, H. Somekawa, T. Kinoshita, W.J. Kim, and K. Higashi, The Non-Uniform Behavior During ECAE Process by 3-D FVM Simulation, Scr. Mater., 2004, 50, p 1079–1083

O.N. Senkov, S.V. Senkova, J.M. Scott, and D.B. Miracle, Compaction of Amorphous Aluminum Alloy Powder by Direct Extrusion and Equal Channel Angular Extrusion, Mater. Sci. Eng. A, 2005, 393, p 12–21

A.V. Nagasekhar, Y. Tick-Hon, R.K. Guduru, and K.S. Ramakanth, Multipass Equal Channel Angular Extrusion of MgB2 Powder in Tubes, Physica C, 2007, 466, p 174–180

P. Quang, Y.G. Jeong, S.H. Hong, and H.S. Kim, Equal Channel Angular Pressing of Carbon Nanotube Reinforced Metal Matrix Nanocomposites, Key. Eng. Mater., 2006, 326–328, p 325–328

I. Karaman, M. Haouaoui, and H.J. Maier, Nanoparticle Consolidation Using Equal Channel Angular Extrusion at Room Temperature, J. Mater. Sci., 2007, 42, p 1561–1576

K. Matsuki, T. Aida, T. Takeuchi, J. Kusui, and K. Yokoe, Microstructural Characteristics and Superplastic-Like Behavior in Aluminum Powder Alloy Consolidated by Equal-Channel Angular, Acta Mater., 2000, 48, p 2625–2632

J. Robertson, J.T. Im, I. Karaman, K.T. Hartwig, and I.E. Anderson, Consolidation of Amorphous Copper Based Powder by Equal Channel Angular Extrusion, J. Non-Cryst. Solids, 2003, 317, p 144–151

A.T. Procopioa and A. Zavaliangos, Simulation of Multi-Axial Compaction of Granular Media from Loose to High Relative Densities, J. Mech. Phys. Solids, 2005, 53, p 1523–1551

W. Wu, G. Jiang, R.H. Wagoner, and G.S. Daehn, Experimental and Numerical Investigation of Idealized Consolidation Part 1: Static Compaction, Acta Mater., 2000, 48, p 4323–4330

L.H. Han, J.A. Elliott, A.C. Bentham, A. Mills, G.E. Amidon, and B.C. Hancock, A Modified Drucker-Prager Cap Model for Die Compaction Simulation of Pharmaceutical Powders, Int. J. Solid. Struct., 2008, 45, p 3088–3106

H.S. Kim, M.H. Seo, C.-S. Oh, and S.-J. Kim, Equal Channel Angular Pressing of Metallic Powders, Mater. Sci. Forum, 2003, 437–438, p 89–92

S.C. Yoon and H.S. Kim, Equal Channel Angular Pressing of Metallic Powders for Nanostructured Materials, Mater. Sci. Forum, 2006, 503–504, p 221–226

S.C. Yoon, S.-J. Hong, S.I. Hong, and H.S. Kim, Mechanical Properties of Equal Channel Angular Pressed Powder Extrudates of Rapidly Solidified Hypereutectic Al-20 wt% Si Alloy, Mater. Sci. Eng. A, 2007, 449–451, p 966–970

S.C. Lee, S.Y. Ha, K.T. Kim, S.M. Hwang, L.M. Huh, and H.S. Chung, Finite Element Analysis for Deformation Behavior of an Aluminum Alloy Composite Containing SiC Particles and Porosities During ECAP, Mater. Sci. Eng. A, 2004, 371, p 306–312

A.L. Gurson, Continuum Theory of Ductile Rupture by Void Nucleation and Growth: Part I—Yield Criteria and Flow Rules for Porous Ductile Materials, J. Eng. Mater. Technol., 1977, 99, p 2–15

Abaqus Inc, Abaqus Users Manual, Version 6.8-1, 2008

D.P. Delo and R.H. Piehler, Early Stage Consolidation Mechanisms During Hot Isostatic Pressing of Ti-6Al-4V Powder Compacts, Acta Mater., 1999, 47, p 2841–2852

K.T. Kim and M.M. Carroll, Compaction Equations for Strain Hardening Porous Materials, Int. J. Plast., 1987, 3, p 63–73

A.V. Nagasekhar, S.C. Yoon, Y. Tick-Hon, and H.S. Kim, An Experimental Verification of the Finite Element Modelling of Equal Channel Angular Pressing, Comput. Mater. Sci., 2009, 46, p 347–351

M. Furukawa, Z. Horita, and T.G. Langdon, Processing by Equal Channel Angular Pressing: Applications to Grain Boundary Engineering, J. Mater. Sci., 2005, 40, p 909–917

H.S. Kim, M.H. Seo, and S.I. Hong, On the Die Corner Gap Formation in Equal Channel Angular Pressing, Mater. Sci. Eng. A, 2000, 291, p 86–90

A.V. Nagasekhar, Y. Tick-Hon, S. Li, and H.P. Seow, Effect of Acute Tool Angles on Equal Channel Angular Extrusion/Pressing, Mater. Sci. Eng. A, 2005, 410–411, p 269–272

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Haghighi, R.D., Jahromi, A.J. & Jahromi, B.E. Simulation of Aluminum Powder in Tube Compaction Using Equal Channel Angular Extrusion. J. of Materi Eng and Perform 21, 143–152 (2012). https://doi.org/10.1007/s11665-011-9896-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-011-9896-1