Abstract

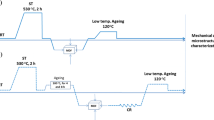

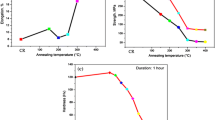

An Al-4Zn-2Mg alloy was subjected to cryorolling (CR) followed by short annealing. An average grain size of ~100 nm was achieved. Cryorolled samples showed large reduction in grain size due to suppression of dynamic recovery and absence of annihilation of dislocations, as compared to room temperature rolled samples. Further, the ultrafine-grained (UFG) Al-4Zn-2Mg alloy when subjected to natural aging showed an improved strength of ~413 MPa with ductility of ~25%, as compared to ~360 MPa and 22% ductility in peak aged condition of coarse-grained alloy. However, UFG alloy in peak aging condition, exhibited a relatively strength (~375 MPa) and 24% ductility combinations than the natural aging condition. The latter is attributed to dynamic precipitation and stored energy. In the present study, it is demonstrated that simultaneous improvement in strength as well as ductility can be achieved for the Al-4Zn-2Mg alloy through CR and controlled heat treatment combinations.

Similar content being viewed by others

References

Z.Y. Liu, G.X. Liang, E.D. Wang, and Z.R. Wang, The Effect of Cumulative Large Plastic Strain on the Structure and Properties of a Cu-Zn Alloy, Mater. Sci. Eng. A, 1998, 242, p 137–140

B. Mingler, H.P. Karnthaler, M. Zehetbauer, and R.Z. Valiev, TEM Investigation of Multidirectionally Deformed Copper, Mater. Sci. Eng. A, 2001, 319–321, p 242–245

C. Xu, M. Furukawa, Z. Horita, and T.G. Langdon, Severe Plastic Deformation as a Processing Tool to Develop Superplastic Metals, J. Alloys Compd., 2004, 378, p 27–34

Z. Horita, T. Fujinami, M. Nemoto, and T.G. Langdon, Equal Channel Angular Pressing of Commercial Aluminum Alloys: Grain Refinement Thermal Stability and Tensile Properties, Metall. Mater. Trans., 2000, A31, p 691–701

S.J. Oh and S.B. Kang, Analysis of the Billet Deformation During Equal Channel Angular Pressing, Mater. Sci. Eng., 2003, A343, p 107–115

Y.Y. Wang, P.L. Sun, P.W. Kao, and C.P. Chang, Effect of Deformation Temperature on the Microstructure Developed in Commercial Purity Aluminum Processed by Equal Channel Angular Extrusion, Scr. Mater., 2004, 50, p 613–617

Y. Saito, H. Utsunomiya, N. Tsuji, and T. Sakai, Novel ultra-High Straining Process for Bulk Materials Development of the Accumulative Roll-Bonding (ARB) Process, Acta Mater., 1999, 47, p 579–583

N. Tsuji, Y. Siato, H. Utsunomiya, and S. Tanigawa, Ultra-Fine Grained Bulk Steel Produced by Accumulative Roll-Bonding (ARB) Process, Scr. Mater., 1999, 40, p 795–800

S.H. Lee, Y. Saito, H. Utsunomiya, N. Tsuji, and T. Sakai, Role of Shear Strain in Ultra Grain Refinement by Accumulative Roll-Bonding (ARB) Process, Scr. Mater., 2002, 46, p 281–285

K.T. Park, H.J. Kwon, W.J. Kim, and Y.S. Kim, Microstructural Characteristics and Thermal Stability of Ultrafine Grained 6061 Al Alloy Fabricated by Accumulative Roll Bonding Process, Mater. Sci. Eng., 2001, A316, p 145–152

J.Y. Huang, Y.T. Zhu, H. Jiang, and T.C. Lowe, Microstructures and Dislocation Configurations in Nanostructured Cu Processed by Repetitive Corrugation and Straightening, Acta Mater., 2001, 49, p 1497–1505

J.Y. Huang, Y.T. Zhu, J. David, and T.C. Lowe, Development of Repetitive Corrugation and Straightening, Mater. Sci. Eng., 2004, A371, p 35–39

Y.T. Zhu, H. Jiang, J.Y. Huang, and T.C. Lowe, A New Route to Bulk Nanostructured Metals, Metall. Mater. Trans., 2001, A32, p 1559–1562

D.H. Shin, J.J. Park, Y.S. Kim, and K.T. Park, Constrained Groove Pressing and Its Application to Grain Refinement of Aluminum, Mater. Sci. Eng., 2002, A328, p 98–103

J.W. Lee and J.J. Park, Numerical and Experimental Investigations of Constrained Groove Pressing and Rolling for Grain Refinement, Mater. Process. Technol., 2002, 130, p 208–213

Y.B. Lee, D.H. Shin, K.T. Park, and W.J. Nam, Effect of Annealing Temperature on Microstructures and Mechanical Properties of a 5083 Al Alloy Deformed at Cryogenic Temperature, Scr. Mater., 2004, 51, p 355–359

T. Shanmugasundaram, B.S. Murty, and V. Subramanya Sarma, Development of Ultrafine Grained High Strength Al-Cu Alloy by Cryorolling, Scr. Mater., 2006, 54, p 2013–2017

S. Cheng, Y.H. Zhao, Y.T. Zhu, and E. Ma, Optimizing the Strength and Ductility of Fine Structured 2024 Al Alloy by Nano-Precipitation, Acta Mater., 2007, 55, p 5822–5832

D. Chu and J.W. Morris, Influence of Grain Structure and Solute Composition on the Work Hardening Behavior of Aluminium at Cryogenic Temperatures, LBL 34019 Lawrence Berkeley Laboratory and University of California

P.N. Adler, R. Delasi, and G. Geschwind, Influence of Microstructure on the Mechanical Properties and Stress Corrosion Susceptibility of 7075 Aluminum Alloy, Metall. Trans., 1972, A3, p 3191–3200

J.T. Staley, Aging Kinetics of Aluminum Alloy 7050, Metal. Trans., 1974, A5, p 929–932

O.B. Lung, Y. Ji-Gang, and Y. Chen-Kuo, Effects of Step-Quench and Aging on Mechanical Properties and Resistance to Stress Corrosion Cracking of 7050 Aluminum Alloy, Mater. Trans. JIM, 2000, 41, p 783–789

Y.H. Zhao, X.Z. Zhao, X.Z. Liao, Z. Jin, R.Z. Valiev, and Y.T. Zhu, Microstructures and Mechanical Properties of Ultrafine Grained 7075 Al Alloy Processed by ECAP and Their Evolutions During Annealing, Acta Mater., 2004, 52, p 4589–4599

A. Deschamps, M. Niewczas, F. Bley, Y. Brechet, D. Embury, L. Lesinq, and F. Livet, Low Temperature Dynamic Precipitation in a Supersaturated Al-Zn-Mg Alloy and Related Strain Hardening, Philos. Mag., 1999, A79, p 2485–2504

L.J. Zheng, C.Q. Chen, T.T. Zhou, P.Y. Liu, and M.G. Zeng, Structure and Properties of Ultrafine-Grained Al-Zn-Mg-Cu and Al-Cu-Mg-Mn Alloys Fabricated by ECA Pressing Combined With Thermal Treatment, Mater. Charact., 2002, 49, p 455–461

Acknowledgments

The authors are grateful to Dr. S. Srikanth, Director, National Metallurgical Laboratory, Jamshedpur, India for his encouragement and extending the necessary support for the work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gopala Krishna, K., Singh, N., Venkateswarlu, K. et al. Tensile Behavior of Ultrafine-Grained Al-4Zn-2Mg Alloy Produced by Cryorolling. J. of Materi Eng and Perform 20, 1569–1574 (2011). https://doi.org/10.1007/s11665-011-9843-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-011-9843-1