Abstract

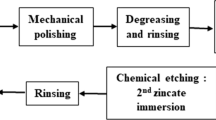

Metallic coatings can be used to improve the wear and corrosion resistance of Al alloys. In this study, Ni was used as a candidate material for such a coating which was applied on the surface of Al 2014 alloy using electrodeposition in a standard Watt’s bath. A two-step heat treatment procedure was employed that served to increase the adhesion as well as hardness of Ni. Deposition was undertaken for different durations using both galvanostatic and potentiostatic techniques. The effect of deposition parameters such as surface finish, current, potential, temperature, pH level and duration on the microstructure, adhesion, and surface properties of the Ni deposit was studied. Materials characterization was performed using scanning electron microscopy, atomic force microscopy, and x-ray diffraction. Cross-sectional scanning transmission electron microscope images revealed the fine-grained (10 nm) structure of Ni initially deposited at the Ni-Al alloy substrate. Microhardness, adhesion, and corrosion behavior of the Ni deposit were evaluated. Experimental results indicate that deposition by galvanostatic technique on 1 μm surface finish at 45 °C with a pH level maintained at 3.6 represented the optimum conditions to generate a uniform Ni deposit on Al 2014. It was concluded that Ni deposition can be used to improve the surface properties of Al alloys.

Similar content being viewed by others

References

P. Hagans and C.M. Haas, Influence of Metallurgy on the Protective Mechanism of Chromium-Based Conversion Coatings on Aluminum-Copper Alloys, Surf. Interface Anal., 1994, 21, p 65–78

A.K. Mishra and R. Balasubramaniam, Corrosion Inhibition of Aluminum Alloy 2014 by Rare Earth Chlorides, Corros. Sci., 2007, 49, p 1027–1044

Y. Odani, Aluminium Alloys, Met. Powder Rep., 1994, 49, p 36–40

M.J. Ghazali, Wear Characteristic of Several Commercial Wrought Aluminium Alloys Against Tool Steel, J. Kejuru., 2006, 18, p 49–56

D. Pletcher and F.C. Walsh, Industrial Electrochemistry, 2nd ed., Chapman and Hall, London, 1990

J.K. Dennis and T.E. Such, Nickel and Chromium Plating, Butterworth, London, 1986

C.P. Steffani, J.W. Dini, J.R. Groza, and A. Palazoglu, Electrodeposition and Corrosion Resistance of Ni-W-B Coatings, J. Mater. Eng. Perform., 1997, 6/4, p 413–416

F. Cai, X. Huang, Q. Yang, and D. Nagy, Effect of Microstructure on the Solid Particle Erosion Properties of Ni Plating, J. Mater. Eng. Perform., 2009, 18/3, p 305–311

V.F.C. Lins, E.S. Cecconello, and T. Matencio, Effect of the Current Density on Morphology, Porosity, and Tribological Properties of Electrodeposited Nickel on Copper, J. Mater. Eng. Perform., 2008, 17/5, p 741–745

U. Klement, L. Hollang, S.R. Dey, M. Battabyal, O.V. Mishin, and W. Skrotzki, Effect of Annealing on Microstructural Development and Grain Orientation in Electrodeposited Ni, Texture and Anisotropy of Polycrystals III, Solid State Phenomena Series, Vol 160, Trans Tech Publications Inc., Stafa-Zurich, Switzerland, 2010, p 235-240

G.Z. Meng, F.L. Sun, Y.W. Shaoa, T. Zhang, F.H. Wang, C.F. Dong, and X.G. Li, Effect of Phytic Acid on the Microstructure and Corrosion Resistance of Ni Coating, Electrochim. Acta, 2010, 55/20, p 5990–5995

M.M. Kamel, Z.M. Anwer, I.T. Abdel-Salam, and I.S. Ibrahim, Nickel Electrodeposition from Novel Lactate Bath, Trans. Inst. Met. Finish., 2010, 88(4), p 191–197

A. Shibata, H. Noda, M. Sone, and Y. Higo, Microstructural Development of an Electrodeposited Ni Layer, Thin Solid Films, 2010, 518(18), p 5153–5158

J.X. Kang, W.Z. Zhao, and G.F. Zhang, Influence of Electrodeposition Parameters on the Deposition Rate and Microhardness of Nanocrystalline Ni Coatings, Surf. Coat. Technol., 2009, 203(13), p 1815–1818

A.M. El-Sherik, J. Shirokoff, and U. Erb, Stress Measurements in Nanocrystalline Ni Electrodeposits, J. Alloys Compd., 2005, 389, p 140–143

M. Holm and T.J. O’Keefe, Evaluation of Nickel Deposition by Electrochemical Impedance Spectroscopy, J. Appl. Electrochem., 2000, 30, p 1125–1132

A.M. El-Sherik, U. Erb, and J. Page, Microstructural Evolution in Pulse Plated Nickel Electrodeposits, Surf. Coat. Technol., 1996, 88, p 70–78

E. Toth-Kadar, I. Bakonyi, L. Pogany, and A. Cziraki, Microstructure and Electrical Transport Properties of Pulsed-Plated Nanocrystalline Nickel Electrodeposits, Surf. Coat. Technol., 1997, 88, p 57–65

I. Bakonyi, E. Toth-Kadar, L. Pogany, A. Cziraki, I. Gerocs, K. Varga-Josepovits, B. Arnold, and K. Wetzig, Preparation and Characterization of d.c.-Plated Nanocrystalline Nickel Electrodeposits, Surf. Coat. Technol., 1996, 78, p 124–136

D.-T. Chin, Mass Transfer and Current-Potential Relation in Pulse Electrolysis, J. Electrochem. Soc., 1983, 130, p 1657–1667

A. Cziraki, I. Gerocs, B. Fogarassy, E. Toth-Kadar, and I. Bakonyi, Microstructure and Growth of Electrodeposited Nanocrystalline Nickel Foils, J. Mater. Sci., 1994, 29, p 4771–4777

Y. Xuetao, W. Yu, S. Dongbai, and Y. Hongying, Influence of Pulse Parameters on the Microstructure and Microhardness of Nickel Electrodeposits, Surf. Coat. Technol., 2008, 202, p 1895–1903

J.M. Molina, R.A. Saravanan, J. Narciso, and E. Louis, Surface Modification of 2014 Aluminium Alloy–Al2O3 Particles Composites by Nickel Electrochemical Deposition, Mater. Sci. Eng., 2004, 383, p 299–306

Y. Liu, P. Skeldon, G.E. Thompson, H. Habazaki, and K. Shimizu, Chromate Conversion Coatings on Aluminium-Copper Alloys, Corros. Sci., 2005, 47, p 341–354

Acknowledgments

The authors wish to acknowledge the support of Center of Research Excellence in Corrosion (CoRE-C), Ministry of Higher Education and the Research Institute at the King Fahd University of Petroleum & Minerals, Dhahran, Saudi Arabia.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ul-Hamid, A., Quddus, A., Dafalla, H. et al. Electrochemical Deposition of Ni on an Al-Cu Alloy. J. of Materi Eng and Perform 21, 213–221 (2012). https://doi.org/10.1007/s11665-010-9816-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-010-9816-9