Abstract

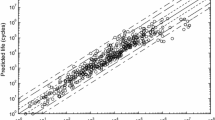

Several methods for estimating fatigue properties of wrought aluminum alloys from simple tensile data or hardness were discussed. Among them, Park-Song’s modified Mitchell’s method provided the best estimation results in low fatigue life regime. Roessle-Fatemi’s hardness method tends to be very erroneous in the present estimations. None of the investigated methods provide the satisfactory estimation results in the case of N f > 3 × 104 cycles. Besides, correlation between ultimate tensile strength and Brinell hardness was developed. Then, the modified Mitchell’s method utilizing the ultimate tensile strength predicted from Brinell hardness was proposed in this study and successfully applied to estimate fatigue properties for wrought aluminum alloys. This simple method requires only Brinell hardness and modulus of elasticity as inputs, both of which are either commonly available or easily measurable. Prediction capability of this method was evaluated for wrought aluminum alloys with hardness between 120 and 157 HB. Results show that the proposed method provides the best life predictions for wrought aluminum alloys.

Similar content being viewed by others

References

S.S. Manson, Fatigue: A Complex Subject-Some Simple Approximation, Exp. Mech., 1965, 5, p 193–226

M.R. Mitchell, Fundamental of Modern Fatigue Analysis for Design, ASM Handbook, Fatigue & Fracture Vol 19, 1996, p 227–249

U. Muralidharan and S.S. Manson, A Modified Universal Slopes Equation for Estimation of Fatigue Characteristic of Metals, J. Eng. Mater. Technol., 1988, 110, p 55–58

A. Bäumel, Jr. and T. Seeger, Materials Data for Cyclic Loading, Supplement 1, Elsevier Science Publishers, Amsterdam, 1990

J.H. Ong, An Improved Technique for the Prediction of Axial Fatigue Life from Tensile Data, Int. J. Fatigue, 1993, 15(3), p 213–219

M.A. Meggiolaro and J.T.P. Castro, Statistical Evaluation of Strain-Life Fatigue Crack Initiation Predictions, Int. J. Fatigue, 2004, 26, p 463–476

M.L. Roessle and A. Fatemi, A Strain-Controlled Fatigue Properties of Steels and Some Simple Approximations, Int. J. Fatigue, 2000, 22, p 495–511

J.H. Park and J.H. Song, New Estimation Method of Fatigue Properties of Aluminum Alloys, J. Eng. Mater. Technol., 2003, 125, p 208–214

J.H. Park and J.H. Song, Detailed Evaluation of Methods for Estimation of Fatigue Properties, Int. J. Fatigue, 1995, 17(5), p 365–373

W.S. Jeon and J.H. Song, An Expert System for Estimation of Fatigue Properties of Metallic Materials, Int. J. Fatigue, 2002, 24, p 685–698

K.S. Kim, X. Chen, C. Han, and H.W. Lee, Estimation Methods for Fatigue Properties of Steels Under Axial and Torsional Loading, Int. J. Fatigue, 2002, 24, p 783–793

K.S. Lee and J.H. Song, Estimation Methods for Strain-Life Fatigue Properties from Hardness, Int. J. Fatigue, 2006, 28, p 286–400

Science and Technology Committee of Aeronautic Engineering Department, “Handbook of Strain Fatigue Analysis,” Science Publishing House, Beijing, China, 1987 (in Chinese)

R.W. Smith, M.H. Hirschberg, and S.S. Manson, “Fatigue Behavior of Materials Under Strain Cycling in Low and Intermediate Life Range.” NASA, Technical Note D-1574, Levis Research Center, Cleveland, Ohio, April 1963.

Y.Y. Wang, “Fatigue Behavior and Fatigue Life Prediction of Metals Under Multiaxial Cyclic Loading,” Ph.D, Dissertation, Nanjing University of Aeronautics and Astronautics, 2005 (in Chinese)

L.E. Tucker, R.W. Landgraf, and W.R. Brose. Technical Report on Fatigue Properties. SAE, J1099, 1979.

T.W. Zhao and Y.Y. Jiang, Fatigue of 7075-T651 Aluminum Alloy, Int. J. Fatigue, 2008, 30, p 834–849

JSMS, Data Book on Fatigue Strength of Metallic Materials, Soc. Mater. Sci. Jpn., 1998, 1(2.3).

ASTM, “Standard Hardness Conversion Tables for Metals,” Annual Book of ASTM STD E140-97, Vol 5. ASTM, USA, 2000, p 1–21.

Committee for Practical Handbook of Engineering Materials, Practical Handbook of Engineering Materials: Aluminum alloys, Magnesium Alloys and Titanium alloys, Standards Press of China, Beijing, China, 1989 (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, J., Zhang, Zp., Sun, Q. et al. A Modified Method to Estimate Fatigue Parameters of Wrought Aluminum Alloys. J. of Materi Eng and Perform 20, 1323–1329 (2011). https://doi.org/10.1007/s11665-010-9765-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-010-9765-3