Abstract

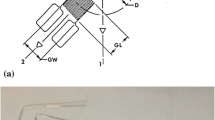

The objective of this study is to determine the effect of solution treatment temperature, quenching media, and various machining sequences on the warpage behavior of aluminum 7249 alloy aged to T6 and T7′ tempers. Large extrusions of 7249 aluminum alloy with fins were cut into 108 “T” sections. The samples were solution-treated, aged, and machined. Three solution temperatures (445, 474, and 505 °C), two quenching media (water and 20% polyalkylene glycol), two aging treatments (T6 and T7′), and three machine sequences were used. The flatness of the samples was measured on the surfaces orthogonal to the z-axis. Three points were on top of both shoulders (six total), six were at the bottom of the sample, and six were on the top of the fin, in the cases where the fin was not milled off. They were then averaged together by surface to represent the overall warpage of each sample.

Similar content being viewed by others

References

O.S. Es-Said, T.M. Ruperto, S.L. Vasquez, A.Y. Yue, D.J. Manriques, J.C. Quilla, S.H. Harris, S. Hannan, J. Foyos, E.W. Lee, B. Pregger, N. Abourialy, and J. Ogren, Warpage Behavior of 7050 Aluminum Alloy Extrusions, J. Mater. Eng. Perform., 2007, 16, p 242–247

H. Boyer, Quenching and Control of Distortion, ASM International, Metals Park, OH, 1988

C. Bates, Selecting Quenchants to Maximize Tensile Properties and Minimize Distortion in Aluminum Parts, J. Heat Treat., 1987, 5, p 27–40

J. Collins and C. Maduell, Polyalkylene Glycol Quenching of Aluminum Alloys, International Corrosion Forum, National Association of Corrosion Engineers, Houston, TX, 1977, p 7 (Pamphlet)

Santa Clara University, School of Engineering, http://www.scudc.scu.edu/cmdoc/dg_doc/develop/process/physics/b3500001.htm.

Warpage, http://www.efunda.com/designstandards/plastic_design/warpage.cfm, Copyright© 2010 eFunda, Inc

“ASTM Standard A1030/A1030M-05, 2010, Standard Practice for Measuring Flatness Characteristics of Steel Sheet Products,” ASTM International, West Conshohocken, PA, 2010. doi: 10.1520/A1030_A1030M-05, www.astm.org

M. Iskandar, D. Reyes, Y. Gaxiola, E. Fudge, J. Foyos, E.W. Lee, P. Kalu, H. Garmestani, and O.S. Es-Said, The Effect of Varying the Solution Treatment Temperature, Natural Aging Treatment and Artificial Aging Treatment on the Mechanical Strength of 7249 Aluminum Alloy, Mater Sci Forum, 2002, 396–402, p 1121–1126

Matweb, http://www.matweb.com/search/DataSheet.aspx?MatGUID=4a884a58c3bb4814b2ed1d25fda9b7d0&ckck=1, Copyright 1996-2010 by Automation Creations, Inc

J. Foyos, E.W. Lee, C. Kumor, M. Smith, C. Hou, and O. S. Es-Said, Feasibility Study of the Warpage of 7050 Aluminum Plates, Light Weight Alloys for Aerospace Applications IV, E.W. Lee, W.E. Frazier, K. Jatta, and N. Kim, Eds., TMS, 1997, p 73–83

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Keleshian, N., Kyser, R., Rodriguez, J. et al. On the Distortion and Warpage of 7249 Aluminum Alloy After Quenching and Machining. J. of Materi Eng and Perform 20, 1230–1234 (2011). https://doi.org/10.1007/s11665-010-9756-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-010-9756-4