Abstract

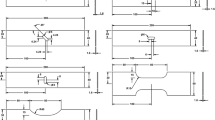

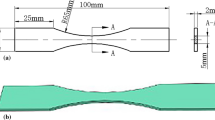

Corrosion is one of the most damaging mechanisms in aluminum alloys commonly used in aerospace engineering structures. Cracks usually initiate from the pits/defects, and currently, there are no measurement probes that can estimate the stress environment around corrosion pits. In this article, a systematic study is conducted to investigate the evolution of corrosion-damage-induced stresses in aluminum alloy 2024-T3 as a function of time. Corrosion experiments were conducted on a metal sample under controlled electrochemical conditions and the surfaces were imaged using AFM techniques. A computational procedure was developed to investigate the stresses resulting from corrosion damage/pits using the AFM image, CAD, and finite element analysis. Analysis was also carried out on corroded specimens under bending and tension loadings in order to see how the loading affects the induced stresses. The results indicated that the stress distribution and levels on the corroded surface varied due to irregularities and randomness in the metal sample. The results also indicated that the stress initially increases and reaches a plateau with increasing corrosion time and may be responsible for failure (crack initiation) of the metals.

Similar content being viewed by others

References

P. Marcus and J. Oudar, Ed., Corrosion Mechanisms in Theory and Practice, Marcel Dekker, Inc., New York, 1995

L.L. Shreir, R.A. Jarman, and C.T. Burstein, Ed., Corrosion-Metal/Environmental Reactions, 3rd ed., Butterworth & Heinemann Ltd, Oxford, 1994

H.H. Strehblow, Mechanisms of Pitting Corrosion, Corrosion Mechanisms in Theory and Practice, P. Marcus and J. Oudar, Ed., Marcel Dekker, Inc., New York, 1995, p 201–238

R.P. Wei, C.M. Liao, and M. Gao, A Transmission Electron Microscopy Study of 7075-T6 and 2024-T3 Aluminum Alloys, Metallurgical and Materials Transactions A, 1998, 29A, p 1153–1160

K. Jones and D.W. Hoeppner, Prior Corrosion and Fatigue of 2024-T3 Aluminum Alloy, Corros. Sci., 2006, 48, p 3109–3122

D.W. Hoeppner, Fatigue Mechanisms STP, Vol 675, American Society for Testing and Materials (ASTM), Philadelphia, PA, 1979, p 841–870

G.T. Burstein, C. Liu, R.M. Souto, and S.P. Vines, Origins of Pitting Corrosion, Corros. Eng. Sci. Technol., 2004, 39, p 25–30

G.N. Frantiziskonis, L.B. Simon, J. Woo, and T.E. Matikas, Multiscale Characterization of Pitting Corrosion and Application to an Aluminum Alloy, Eur. J. Mech. A Solids, 2000, 19, p 309–318

S.I. Rokhlin, J.Y. Kim, H. Nagy, and B. Zoofan, Effect of Pitting Corrosion on Fatigue Crack Initiation and Fatigue Life, Eng. Fract. Mech., 1999, 2, p 425–444

S. Ishihara, S. Saka, Z.Y. Nan, T. Goshima, and S. Sunada, Prediction of Corrosion Fatigue Lives of Aluminum Alloy on the Basis of Corrosion Pit Growth Law, Fatig. Fract. Eng. Mater. Struct., 2006, 29, p 472–480

H.S. Isaacs, Initiation of Stress Corrosion Cracking of Sensitized Type 304 Stainless Steel in Ductile Thiosulfate Solution, J. Electrochem. Soc., 1988, 135, p 2180–2183

T. Suter and H. Bohni, A New Microelectrochemical Method to Study Pit Initiation on Stainless Steels, Electrochim. Acta, 1997, 42, p 275–328

R. Oltra and V. Vignal, Recent Advances in Local Probe Techniques in Corrosion Research—Analysis of the Role of Stress on Pitting Sensitivity, Corros. Sci., 2007, 49, p 158–165

C.H. Paik and R.C. Alkire, Role of Sulfide Inclusions on Localized Corrosion of Ni200 in NaCl Solutions, J. Electrochem. Soc., 2001, 148, p B276–B281

P. Schmutz and G.S. Frankel, Corrosion Study of AA2024-T3 by Scanning Kelvin Probe Force Microscopy and In Situ Atomic Force Microscopy Scratching, J. Electrochem. Soc., 1998, 145, p 2295–2306

R.M. Pidaparti and R.R. Patel, Correlation Between Corrosion Pits and Stresses in Al Alloys, Mater. Lett., 2008, 62(30), p 4497–4499

Rhinoceros 4.0, Rhino 4.0 Tutorial, McNeel North America, Seattle, WA, 2007

SolidWorks, SolidWorks Tutorial, SolidWorks Corporation, Concord, MA, 2007

ANSYS 11.0, ANSYS Tutorial, ANSYS Inc., Canonsburg, PA, 2007

Acknowledgments

The authors thank the U. S. National Science Foundation for sponsoring this research through grant DMR-0505039.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pidaparti, R.M., Patel, R.R. Modeling the Evolution of Stresses Induced by Corrosion Damage in Metals. J. of Materi Eng and Perform 20, 1114–1120 (2011). https://doi.org/10.1007/s11665-010-9753-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-010-9753-7