Abstract

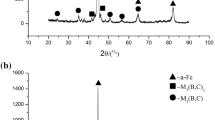

The H11 hot work tool steel was boronized at various processing parameters, austenitized, quenched, and tempered to a core hardness of 47-48 HRC. Microstructure, phase constitution, and microhardness of boronized layers were investigated. Effect of boronized region on the bulk properties was determined by the Charpy impact test. Structure of boronized regions is formed by the compound layers and diffusion inter-layer. The compound layers consisted of only (Fe,Cr)2B phase, but in the case of longer processing time, they contained also of the (Fe,Cr)B-phase. The inter-layer contained enhanced portion of carbides, formed due to carbon diffusion from the boride compounds toward the substrate. Microhardness of boronized layers exceeded considerably 2000 HV 0.1. However, boronizing led to a substantial lowering of the Charpy impact toughness of the material.

Similar content being viewed by others

References

V. Sedlická, M. Hudáková, R. Moravčík, and P. Grgač, X-Ray Phase Analysis of Boronized Layers on the Tool Steels of Ledeburite Type, Proc. of Int. Conf. “Coatings and layers 2005”, May 21-23, 2005 (Demanovská dolina, Slovak Republic), ZTS MATEC Dubnica n. Váhom, 2005, p 168–173 (In Slovak)

W. Grafen and B. Edenhofer, New Developments in Thermo-Chemical Diffusion Processes, Surf. Coat. Technol., 2005, 200, p 1830–1836

M. Kusý, V. Sedlická, M. Hudáková, and P. Grgač, X-Ray Diffraction Analysis of Boronized K 190 PM Tool Steel, Proc. of 21st Int. Conf. on Heat Treatment, November 28-30, 2006 (Jihlava, Czech Republic), ATZK Prague, 2006, p 289–294 (In Czech)

M. Hudáková, M. Kusý, V. Sedlická, and P. Grgač, Analysis of the Boronized Layer on K 190 PM Tool Steel, Mater. Technol., 2007, 41(2), p 81–84

M. Hudáková, M. Kusý, V. Sedlická, and P. Grgač, Contact Diffusion Boronizing of X210Cr12 Tool Steel, Proc. of Int. Conf. “Coatings and Layers 2007”, October 28-30, 2007 (Rožnov pod Radhoštěm, Czech Republic), LISS Rožnov pod Radhoštěm, 2007, CD-ROM

P. Jurči, F. Hnilica, and J. Cejp, Changes of the Fracture Behaviour of Medium-Alloyed Ledeburitic Tool Steel After Plasma Nitriding, Mater. Technol., 2007, 41, p 231–236

F. Hnilica, J. Čmakal, and P. Jurči, Changes to the Fracture Behaviour of the Cr-V Ledeburitic Steel Vanadis 6 as a Result of Plasma Nitriding, Mater. Technol., 2004, 38, p 263–268

I. Campos, R. Torres, G. Ramirez, R. Ganem, and J. Martinez, Growth Kinetics of Doride Layers: Dimensional Analysis, Appl. Surf. Sci., 2006, 252, p 8662–8667

I. Campos, M. Farah, N. Lopez, G. Bermudez, G. Rodriguez, and C. Villa Velazquez, Evaluation of the Tool Life and Fracture Toughness of Cutting Tools Boronized by the Paste Boriding Process, Appl. Surf. Sci., 2008, 254, p 2967–2974

U. Sen and S. Sen, The Fracture Toughness of Borides Formed on Boronized Cold Work Tool Steels, Mater. Charact., 2003, 50, p 261–267

V.I. Dybkov, W. Lengauer, and K. Barmak, Formation of Boride Layers at the Fe-10%Cr Alloy-Boron Interface, J. Alloys Compd., 2005, 398, p 113–122

Ch. Li, B. Shen, G. Li, and Ch. Yang, Effect of Boronizing Temperature and Time on Microstructure and Abrasion Wear Resistance of Cr12Mn2V2 High Chromium Cast Iron, Surf. Coat. Technol., 2008, 202, p 5882–5886

Acknowledgments

The investigations were carried out on devices purchased thanks to the release of European structural funds within the project ICDAM.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jurči, P., Hudáková, M. Diffusion Boronizing of H11 Hot Work Tool Steel. J. of Materi Eng and Perform 20, 1180–1187 (2011). https://doi.org/10.1007/s11665-010-9750-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-010-9750-x