Abstract

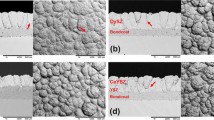

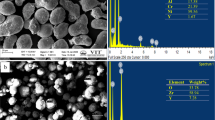

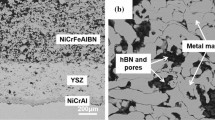

The material commonly used in low-pressure high-rating super critical/ultra super critical steam turbines as well as guide and moving blades of high speed aero compressors is Ti6Al4V alloy. These blades are severely affected owing to erosion which leads to drop in efficiency and increase in maintenance cost. This article deals with SHS 7170 coating on Ti6Al4V alloy using twin wire arc spraying (TWAS), enhancing its bonding by providing a thin bond coat and then treating with high-power diode laser (HPDL). Significant improvement in erosion resistance of this multilayer coating has been achieved because of the formation of fine-grained micro structure due to rapid heating and cooling rates associated with the laser surface treatment. After laser surface treatment, the fracture toughness of this multilayer has improved manifold. The water droplet and particulate erosion test results along with the damage mechanism are reported and discussed in this article.

Similar content being viewed by others

References

E.R. Buchman, An Overview of Erosion Resistant Coatings for Steam Path Surfaces, Turbo Machinery International, Jan/Feb 1987, p 25–28

B.S. Mann, Solid Particle Erosion and Protective Layer for Steam Turbine Blading, Wear, 1999, 224, p 8–12

J.I. Cofer, IV, J.K. Reinker, and W.J. Summer, Advances in Steam Path Technology, GE Power Systems Paper, GER-3713

W. Tabakoff, M. Metwally, and A. Hamed, High Temperature Coatings for Protection Against Turbine Deterioration, Trans. ASME J. Eng. Gas Turbine Power, 1995, 117, p 146–155

M. Metwally, W. Tabakoff, and A. Hamed, Blade Erosion in Automotive Gas Turbine Engine, Trans. ASME J. Eng. Gas Turbine Power, 1995, 117, p 213–219

B.S. Mann and V. Arya, HVOF Coating and Surface Treatment for Enhancing Droplet Erosion Resistance for Steam Turbine Blades, Wear, 2003, 254, p 652–667

B.K. Pant, V. Arya, and B.S. Mann, Enhanced Droplet Erosion Resistance of Laser-Treated Nano Structured TWAS and Plasma Ion-Nitro Carburized Coatings for High-Rating Steam Turbine Components, J. Therm. Spray Tech., Published online 30th April, 2010

D.J. Brangan, M. Breitsameter, B.E. Meacham, and V. Belashchenko, High Performance Nano Scale Composite Coating for Boiler Applications, J. Therm. Spray Tech., 2005, 14(2), p 196–204

B.Q. Wang and M.W. Seitz, Comparison in Behavior of Iron Base Coatings Sprayed by Three Different Arc Spray Processes, Wear, 2001, 250, p 755–761

S. Dallaire, Hard Arc-Sprayed Coatings with Enhanced Erosion and Abrasion Wear Resistance, J. Therm. Spray Tech., 2001, 10(3), p 511–519

S. Dallaire, H. Levert, and J.G. Legoux, Erosion Resistance of Arc-Sprayed Coatings to Iron Core at 25 and 315 °C, J. Therm. Spray Tech., 2001, 10(2), p 337–350

P. Georgieva, R. Thorpe, A. Yanski, and S. Seal, Nano Composite Materials, an Innovative Turnover for the Wire Arc Spraying Technology, Adv. Mater. Process., 2006, 164(8), p 68–69

Industrial News, New Benchmark Achieved with the Development of Nanoscale coatings Using Electric Arc Spraying, J. Therm. Spray Tech., 2005, 14(1), p 13

S. DePalo, M. Mohanty, H. Marc-Charles, and M. Dorfman, Fracture Toughness of HVOF Sprayed WC-Co Coatings, Therm. Spray: Surf. Eng. Appl., 2000, 5, p 245–250

V. Gorokhovsky, C. Bowman, J. Wallace, D. Van Vorous, J. O’Keefe, V. Champagne, M. Pepi, and W. Tabakoff, LAFAD Hard Ceramic and Cermet Coatings for Erosion and Corrosion Protection of Turbo Machinery Components, Proceedings of ASME Turbo Expo 2009: Power for Land, Sea and Air, GT 2009-59391, 8-12 June 2009, Orlando, Florida, USA, p 1–38

J.R. Cheski, R. Patel, K. Rockaway, H. Osaghae, and M. Christianson, A Large Steam Turbine Retrofit Design and Operation History, Presented at 2005 Power-Gen International Conference Held at Las Vegas, NV, 6 Dec 2005

A. Mujezinovic, Bigger Blades Cut Costs, Modern Power Syst., 2003, 23(2), p 25–27

B. Stanisa and V. Ivnsic, Erosion Behavior and Mechanism for Steam Turbine Rotor Blades, Wear, 1995, 186–187, p 395–400

B. Stanisa, Z. Schauperl, and K. Grilec, Erosion Behavior of Turbine Rotor Blades Installed in the Krsko Nuclear Power Plant, Wear, 2003, 254, p 735–741

B.S. Mann, V. Arya, and P. Joshi, Advanced HVOF Coating and Candidate Materials for Protecting LP Steam Turbine Blades Against Droplet Erosion, J. Mater. Eng. Perform., 2005, 14(4), p 487–494

M. Naeem, Heat Treating with Lasers, Heat Treating Prog., 2005, 5(3), p 47–51

C. Phipps, Laser Applications Overview, The State of Art and the Future Trend in United States, RIKEN Rev. 2003, 50, p 11–19, Focused on Laser Precesion Microfabrication (LPM 2002)

B.S. Mann, V. Arya, A.K. Maiti, M.U.B. Rao, and P. Joshi, Corrosion and Erosion Performance of HVOF/TiAlN PVD Coatings and Candidate Materials for High Pressure Gate Valve Application, Wear, 2006, 260, p 75–82

B.S. Mann, V. Arya, B.K. Pant, and M. Agrawal, High-Power Diode Laser Surface Treatment to Minimize Droplet Erosion of Low-Pressure Steam Turbine Moving Blades, J. Mater. Eng. Perform., 2009, 18(7), p 990–998

Acknowledgments

The authors are thankful to Mr. Venkateswar Reddy for doing Scanning Electron Microscopy, and Dr. (Mrs.) Y. Kalpana for providing information on water chemistry. The authors are also thankful to the management of Corporate R&D for permission to publish this article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mann, B.S., Arya, V. & Pant, B.K. Enhanced Erosion Protection of TWAS Coated Ti6Al4V Alloy Using Boride Bond Coat and Subsequent Laser Treatment. J. of Materi Eng and Perform 20, 932–940 (2011). https://doi.org/10.1007/s11665-010-9735-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-010-9735-9