Abstract

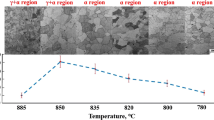

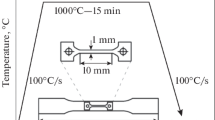

Low-carbon Al-killed hot rolled strips for direct forming, cold rolling, and galvanizing applications are produced from the similar chemistry at Ezz Flat Steel (EFS) through thin slab casting and rolling (TSCR) technology. The desired mechanical and microstructural properties in hot bands for different applications are achieved through control of hot rolling parameters, which in turn control the precipitation and growth of AlN. Nitrogen in solid solution strongly influences the yield strength (YS), ductility, strain aging index (SAI), and other formability properties of steel. The equilibrium solubility of AlN in austenite at different temperatures and its isothermal precipitation have been studied. To achieve the formability properties for direct forming, soluble nitrogen is fixed as AlN by coiling the strip at higher temperatures. For stringent cold forming, boron was added below the stoichiometric ratio with nitrogen, which improved the formability properties dramatically. The requirements of hot band for processing into cold rolled and annealed deep drawing sheets are high SAI and fine-grain microstructure. Higher finish rolling and low coiling temperatures are used to achieve these. Fully processed cold rolled sheets from these hot strips at customer’s end have shown good formability properties. Coil break marks observed in some coils during uncoiling were found to be associated with yielding phenomenon. The spike height (difference between upper and lower yield stresses) and yield point elongation (YPE) were found to be the key material parameters for the break marks. Factors affecting these parameters have been studied and the coiling temperature optimized to overcome the problem.

Similar content being viewed by others

References

F.G. Wilson and T. Gladman, Aluminium Nitride in Steel, Int. Mater. Rev., 1988, 33(5), p 221–286

F. Vodopivec, M. Gabrovsek, and J. Zvokelj, Effects of Finish Rolling Temperature and Carbon Content on Microstructure and Mechanical Anisotropy of 0.04-0.13% C Steels, Trans. ISIJ, 1988, 28, p 117–124

D. Liu, X. Huo, Y. Wang, and X. Sun, Aspects of Microstructure in Low Carbon Steels Produced by the CSP Process, J. Univ. Sci. Technol. Beijing, 2003, 10(4), p 1–6

L. Qingyou, Y. Caifu, L. Xiaokai, Y. Xiaojun, S. Xinjun, T. Zhiling, and G. Yong, Microstructure Evolution of Al-Killed Low Carbon Steel and Microalloyed Steel during Thin Slab Casting and Rolling, 33rd McMaster Symposium on Iron and Steelmaking, Thinner Slab Casting, Hamilton, Canada, June 6-9, 2005, p 1–14

L.S. Darken, R.P. Smith, and E.W. Filer, Solubility of Gaseous Nitrogen in Gamma Iron and the Effect of Alloying Constituents—Aluminium Nitride Precipitation, Trans. AIME, 1951, 191, p 1174–1179

W.C. Leslie, R.L. Rickett, C.L. Dotson, and C.S. Watson, Solution and Precipitation of Aluminium Nitride in Relation to the Structure of Low Carbon Steels, Trans. ASM, 1954, 46, p 1470–1499

H. Yu, Y.L. Kang, H.B. Dong, D.L. Liu, and J. Fu, Analysis on the Behavior of Precipitates in Ultra-Thin Hot Strip of Plain Low Carbon Steel Produced by Compact Strip Production, Acta Metall. Sin., 2002, 15(4), p 375–379

C.W. Siyasiya and W.E. Stumpf, The Effects of Hot Rolling Process and the Nitrogen and Sulphur Content on the Microstructural Development of Al-Killed Hot Rolled Low Carbon Strip Steel, J. SAIMM, 2008, 108, p 481–489

S.K. Paul and S. Mishra, Study on Metallurgical Parameters Affecting Press Forming Characteristics of LPG Steel, Steel India, 1984, 7(2), p 54–60

S.K. Paul, S. Kumar, S. Mishra, and V. Ramaswamy, Assessment of Sheet Metal Formability: Application of the FLD Technique, Trans. IIM, 1992, 45(3), p 163–170

S. Mishra and C. Darmann, Role and Control of Texture in Deep Drawing Steels, Int. Met. Rev., 1982, 27, p 307–320

R.L. Whitely, The Importance of Directionality in Drawing Quality Sheet Steel, Trans. ASM, 1960, 52, p 154–163

J.D. Baird, Strain Aging of Steel—A Critical Review, Iron Steel, 1963, 36(5), p 186–192

F. Jie, L. YangChun, and W. HuaJie, The Precipitation and Effect of Nano Nitrides in HSCL Steel, Sci. China Ser. E Technol. Sci., 2008, 51(7), p 989–998

Strain Aging in Hot Rolled Strips, Vol 1, No 9, R&D Alert, R&D Division, Tata Steel, India, 2000, p 1–4

S.K. Paul, S. Mishra, A.K. De, M.M.S. Sodhi, D.P. Sinha, and R.N. Mukherjee, Commercial Development of Extra Deep Drawing Automotive Sheet Steel in SAIL, SEAISI, Q., 1989, 18(3), p 62–71

P. Choquet et al., Mathematical Model for Predictions of Austenite and Ferrite Microstructures in Hot Rolling Processes, IRSID Report, St. Germain-en-Laye, 1985, p 7

H. Kobayashi, Origin of Break Marks Produced in the Processing of Mild Steel Strip, 41st MWSP Conf. Proc., ISS, Vol 37, 1999, p 743–752

Acknowledgments

The authors are grateful to Mr. M. Ibrahim, Superintendent (Quality Control) and Dr. A. Fathy, Superintendent (Process Control) of Ezz Flat Steel for their keen interest in the work. The authors would also like to express sincere thanks to Mr. Maher Haridy, Metallurgist for his help to evaluate the various mechanical and microstructural properties.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Paul, S.K., Ahmed, U. & Megahed, G.M. Effect of Hot Rolling Process on Microstructure and Properties of Low-Carbon Al-Killed Steels Produced Through TSCR Technology. J. of Materi Eng and Perform 20, 1163–1170 (2011). https://doi.org/10.1007/s11665-010-9711-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-010-9711-4