Abstract

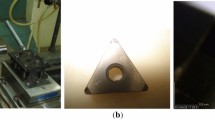

This paper presents the effect of nitriding process parameters on the cutting performance of WC-Co tools. The cutting performance was measured by CNC machining of GG25 cast iron parts. The hardness and phase composition of nitrided layer were determined for different plasma nitriding temperatures and times. The hardness of the nitrided layer increased at all plasma nitrided conditions investigated. However, the machining performance of the cutting inserts varied in the range between a 60% increase and a 40% decrease after plasma nitriding. The maximum number of machined parts was seen when the insert was nitrided at 600 °C-4 h and at 500 °C-4 h.

Similar content being viewed by others

References

D. Pye, Diffusion Surface Treatment Techniques: A Review, Ind. Heat. 2001, p 39–44

B. Podgornik and S. Hogmark, Surface Modification to Improve Friction and Galling Properties of Forming Tools, J. Mater. Process. Technol., 2006, 174, p 334–341

V.V. Uglov, V.M. Anishchik, V.M. Astashynski, N.N. Cherenda, I.G. Gimro, and A.V. Kovyazo, Modification of WC Hard Alloy by Compressive Plasma Flow, Surf. Coat. Technol., 2005, 200, p 245–249

R.K.Y. Fu, S.C.H. Kwok, P. Chen, P. Yang, R.H.C. Ngai, X.B. Tian, and P.K. Chu, Surface Modification of Cemented Carbide Using Plasma Nitriding and Metal Ion Implantation, Surf. Coat. Technol., 2005, 196, p 150–154

P. Hones, R. Consiglio, N. Randall, and F. Lévy, Mechanical Properties of Hard Chromium Tungsten Nitride Coatings, Surf. Coat. Technol., 2000, 125, p 179–184

T. Yamamoto, M. Kawate, H. Hasegawa, and T. Suzuki, Effects of Nitrogen Concentration on Microstructures of WNX Films Synthesized by Cathodic Arc Method, Surf. Coat. Technol., 2005, 193, p 372–374

H.C. Lee and J. Gurland, Hardness and Deformation of Cemented Tungsten Carbide, Mater. Sci. Eng., 1978, 33, p 125–133

R. Konigshofer, A. Eder, W. Lengauer, K. Dreyer, D. Kassel, H.W. Daub, and H. van den Berg, Growth of the Graded Zone and Its Impact on Cutting Performance in High-Pressure Nitrogen Modified Functionally Gradient Hard Metals, J. Alloys Compds., 2004, 366, p 228–232

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hamzaoglu, E., Yilmaz, S. & Gulmez, T. Effect of Plasma Nitriding on the Performance of WC-Co Cutting Tools. J. of Materi Eng and Perform 20, 405–408 (2011). https://doi.org/10.1007/s11665-010-9698-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-010-9698-x